Assembling method of gypsum evacuated mould

An assembly method and cavity mold technology, which are applied in the fields of formwork/template/work frame, on-site preparation of building components, building components, etc., can solve the problem that the strength of reinforced concrete materials cannot be fully exerted, process prefabrication, and transport and unload mold boxes. Difficulties, large plane size of mold box production, etc., to achieve the effect of saving concrete, saving consumption, and high product integrity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

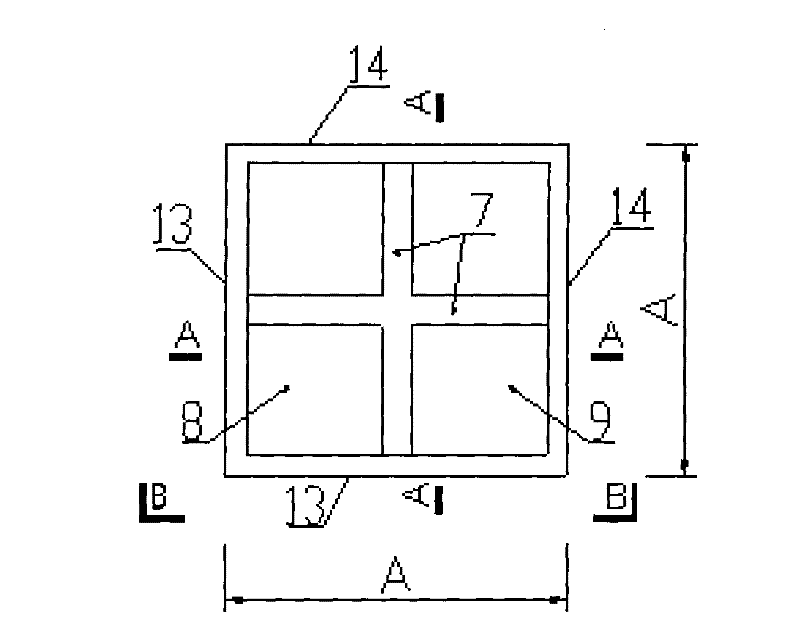

[0035] 1. Connect the four mold boxes to form a large mold box with the bottom exposed: the following combination figure 2 , Figure 5 , Image 6 Explain the specific implementation process. When in use, assembling several plaster cavity mold boxes according to the size of the frame column net includes the following steps:

[0036] (1) Lay horizontal building formwork 1 at the bottom of the floor at the construction site;

[0037] (2) Lay out the line on the formwork to determine the positions of the concrete rib beam 3 and the secondary rib beam 4 of the assembled fixed form box;

[0038] (3) Binding the steel bars of concrete rib beam 3 and secondary rib beam 4;

[0039] (4) Embedded power and telecommunications pipelines at the bottom of the secondary rib 4;

[0040] (5) Lay a number of prefabricated gypsum cavity mold boxes 5 in each regular space enclosed by the rib beam 3 or the secondary rib beam 4. The method is to place the bottom plane 12 of one mold box against the buildin...

Embodiment 2

[0046] 1. Connect the four mold boxes to form a large mold box, the bottom of the mold box is invisible and surrounded by concrete: the following combination figure 2 , Figure 5 , Figure 7 Explain the specific implementation process. When in use, assembling several plaster cavity mold boxes according to the size of the frame column net includes the following steps:

[0047] (1) Lay horizontal building formwork 1 at the bottom of the floor at the construction site;

[0048] (2) Lay out the line on the formwork to determine the positions of the concrete rib beam 3 and the secondary rib beam 4 of the assembled fixed form box;

[0049] (3) Bind the steel bars of the bottom cast-in-place slab 2 on the building template 1. A concrete protective layer pad is set between the slab reinforcement and the template.

[0050] (4) Binding the steel bars of concrete rib beam 3 and secondary rib beam 4;

[0051] (5) Embedded power and telecommunications pipelines at the bottom of the secondary rib ...

Embodiment 3

[0058] Embodiment 3: This embodiment further explains the implementation process. The present invention includes two aspects: Generally speaking, it is suitable for a plaster cavity mold body in which four mold boxes are assembled as a whole. On the other hand, four mold boxes are connected and assembled into one large mold box. Here are the following:

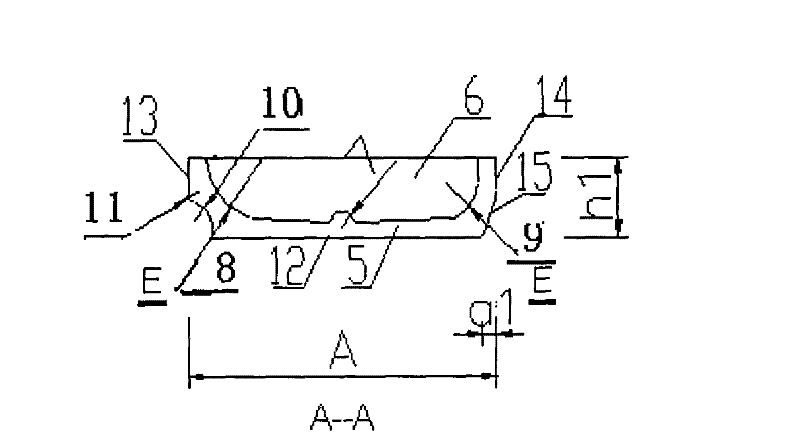

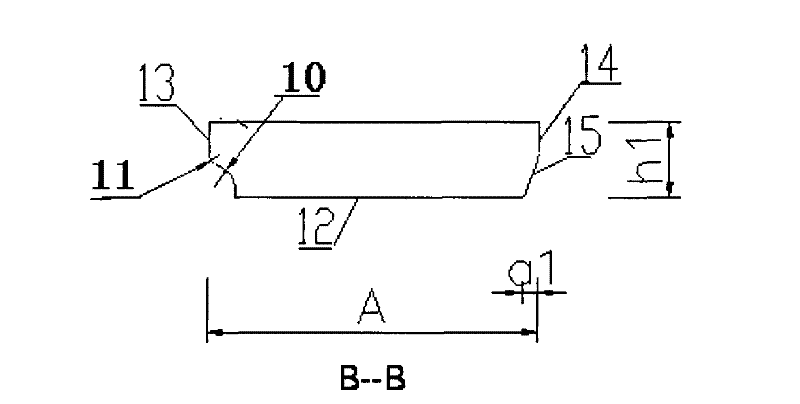

[0059] 1. The shape of the plaster cavity mold box

[0060] The principle to determine the shape of the mold box is to be suitable for assembling the four mold boxes into one; meet the strength requirements; save material and low cost; and the process of connection and assembly is simple.

[0061] The plaster cavity mold box is shaped like Figure one As shown, the external dimension is A×A×h1. Including gypsum layer and cavity, the vertical surface is asymmetrical, the left side of the outer section is composed of vertical vertical surface, arc R1 and arc R2, and the right side of the outer section is made of lead It is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com