System for monitoring curved surface interlaminar extrusion pressure based on array type ultra-thin submissive force sensor

A force sensor and array technology, which is applied in the field of precision measuring devices for the extrusion force between two curved layers, can solve the problems of high cost, inability to complete accurate measurement, and unstable performance, achieve good consistency and improve anti-interference ability. , design simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

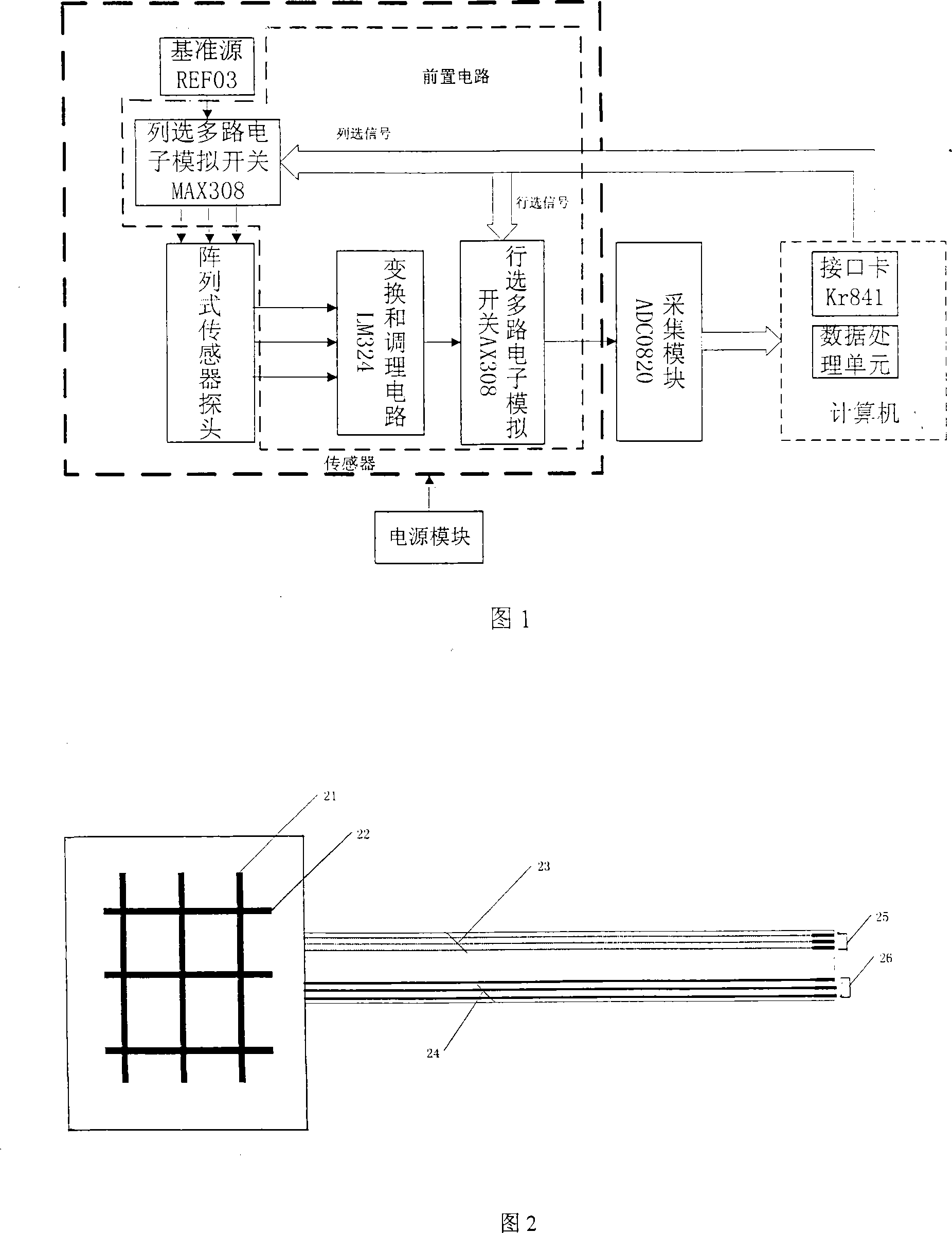

[0025] The curved surface interlayer extrusion force monitoring system based on the array type ultra-thin compliant force sensor proposed by the present invention is described in detail as follows in conjunction with the accompanying drawings and embodiments:

[0026] The composition of the present invention is shown in Figure 1, and the system includes an array sensor made up of an array ultra-thin compliant force sensor probe and a front circuit, a reference source, an acquisition module, a computer containing an interface card and a data processing unit, and a power supply Module; the functions and connections of each component are:

[0027] The power supply module is connected to the sensor and the acquisition module, and outputs +5V and ±12V power supply to provide the required voltage for the sensor and acquisition module;

[0028] The reference source is connected to the array sensor probe by selecting multiple electronic analog switches to provide +2.5V excitation volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com