Optimum design method for two-dimensional heat transfer model of phase change heat storage device

A two-dimensional heat transfer model and phase-change heat storage technology, which can be used in calculations, special data processing applications, instruments, etc., and can solve problems such as low efficiency and large numerical method errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

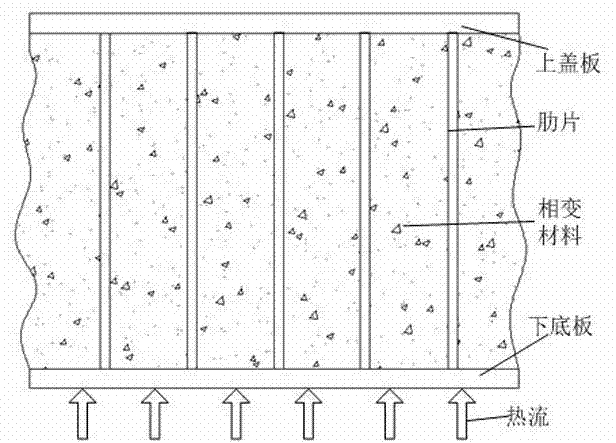

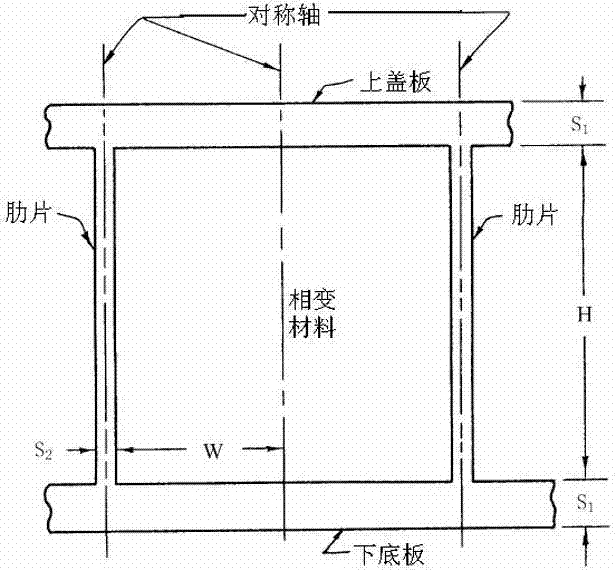

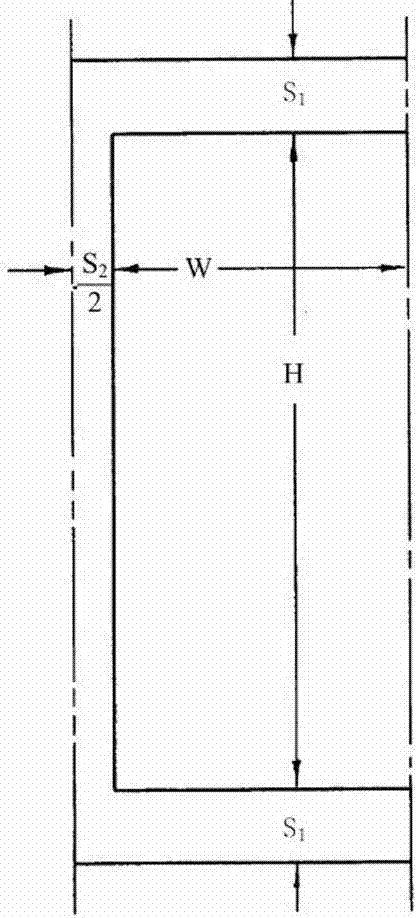

[0058] Example: see Figure 1 to Figure 7 , an optimal design method for a two-dimensional heat transfer model of a phase change heat storage device, comprising the following steps:

[0059] A. Establishment of two-dimensional heat transfer model:

[0060] Because there are metal fins and paraffin-type phase-change materials inside the phase-change heat storage device, the physical parameters such as thermal conductivity, density, and specific heat of the two substances are quite different, and the phase-change materials will change from solid to liquid after absorbing heat. That is, there is a phenomenon of solid / liquid mixing, so the heat transfer relationship inside the two substances is not the same. According to the difference in the heat transfer relationship of the phase change heat storage device, the two-dimensional heat transfer model is divided into four parts (see figure 1 ), which are the lower base plate, the paraffin phase change material, the metal fins and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com