Optimal design method for a finned phase change heat storage device

A phase change heat storage and optimization design technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as low efficiency and large errors, and achieve the effects of high calculation accuracy, optimized design, and meeting engineering design requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

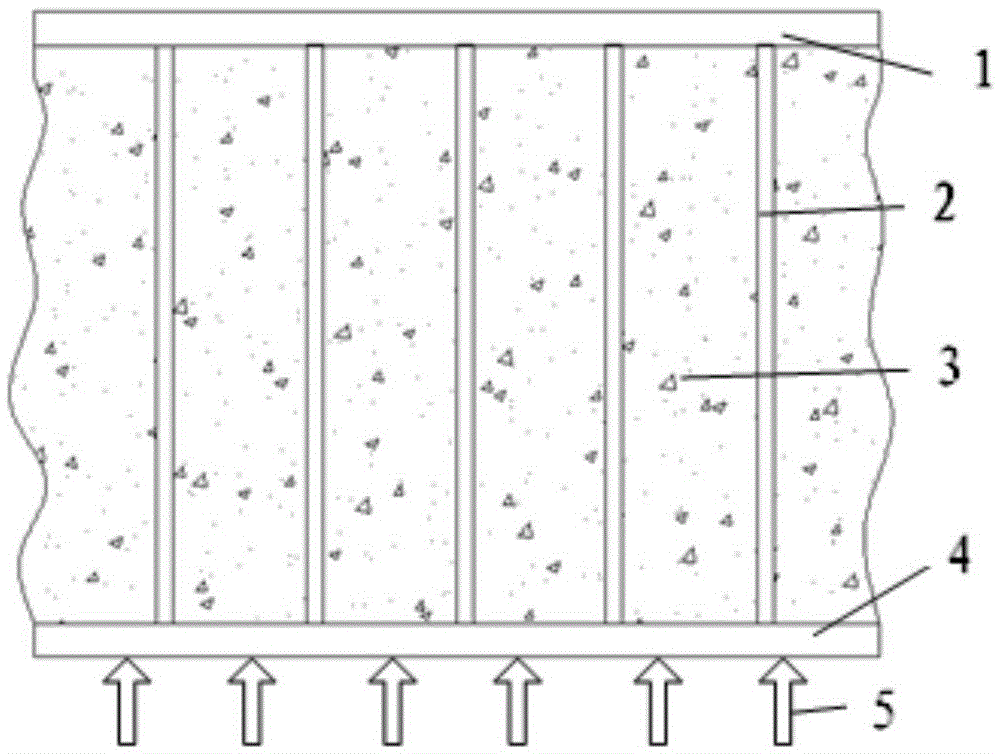

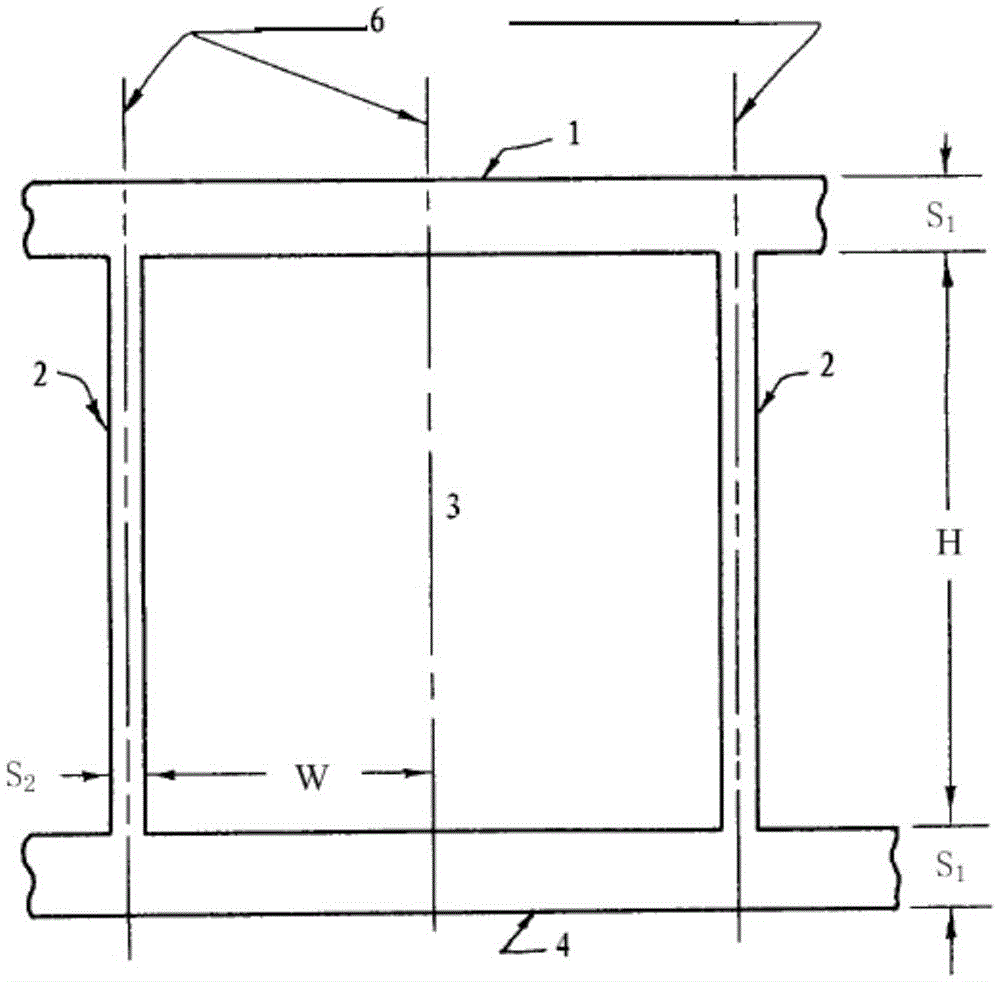

[0033] The present invention proposes an optimal design method for a finned phase change heat storage device in the reentry and return process of a reusable orbital maneuvering vehicle, such as figure 1 As shown, the fin-type phase change heat storage device includes parallel fins 2 installed between the upper cover plate 1 and the lower bottom plate 4 and phase change heat storage materials 3 filled between the fins. The direction of heat flow 5 Such as figure 1 .

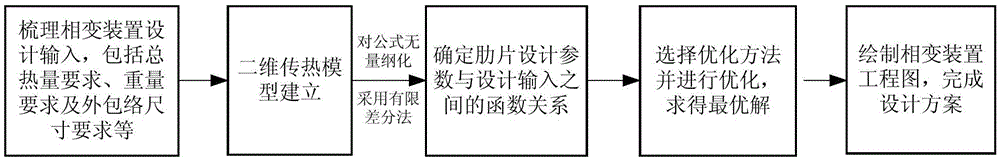

[0034] Such as figure 2 As shown, an optimal design method for a fin-type phase change heat storage device, the steps are as follows:

[0035] (1) When designing a phase change heat storage device, it is first necessary to sort out the design input conditions. According to the relevant requirements for the design of the finned phase change heat storage device during the re-entry and return process of the reusable orbital maneuvering vehicle, the input conditions mainly involved in the present invention include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com