A fluid multifunctional test bench for shield machine

A multi-function, shield machine technology, applied in the testing of machine/structural components, controlling multiple variables, instruments at the same time, etc., can solve the problems of poor detection accuracy, low integration, poor adaptability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

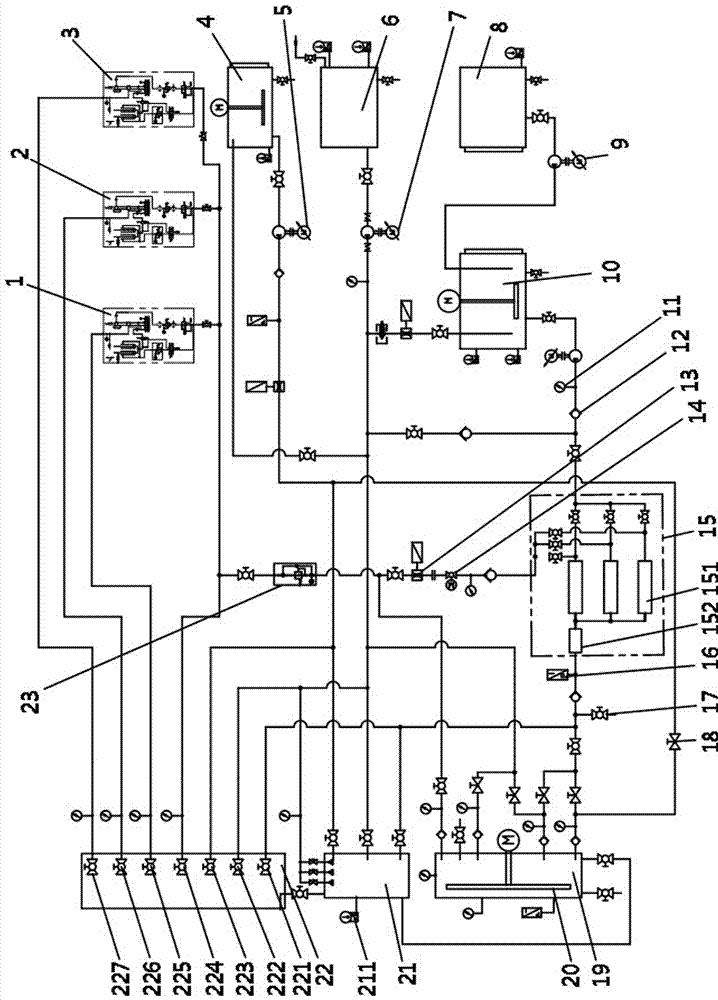

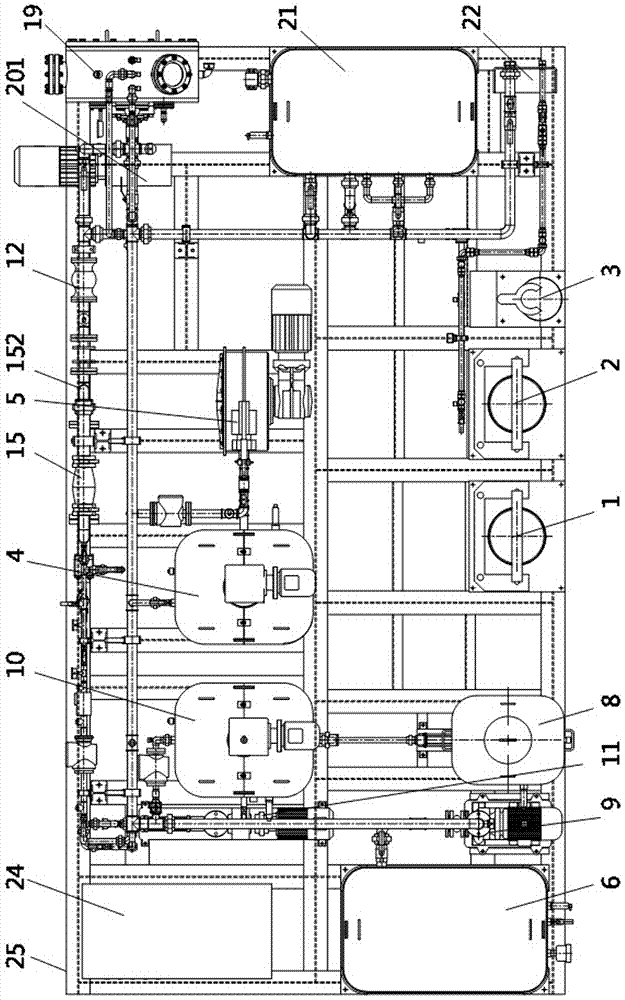

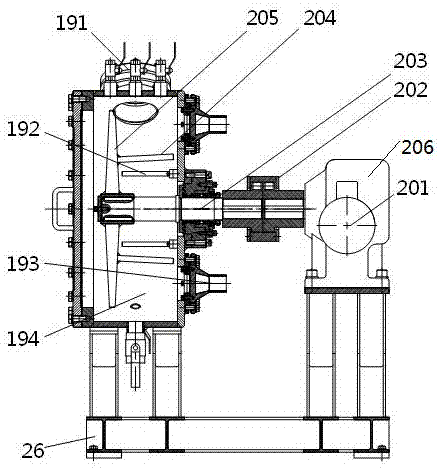

[0026] Example: such as Figure 1-8 As shown, the present invention provides a fluid multifunctional test bench for a shield machine, which is used to simulate the working state of each fluid system of the shield machine under different working conditions, test the performance parameters of the whole system and its components, and output multiple A fluid medium, simulating cutter head stirring and muck improvement experiments, including: cutter head nozzle device 19, stirring device 20, foam system, bentonite system, water system, grease system, air system, monitoring system, collection box 21, external interface Integrated board 22, base 25, pipes and cables. Among them, the water system is connected to the foam system, bentonite system, cutter head nozzle device 19, collection box 21 and external interface integrated board 22 through pipelines; the air system is connected to the foam system, grease system and cutter head nozzle device through the interface of the integrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com