Method for verifying product reliability through temperature-stress-increased accelerated lift test

An accelerated life test and temperature stress technology, which is applied to measuring devices, instruments, and measuring electronics, can solve the problems of high test costs, confidence in analysis results, and long time-consuming, so as to save test funds and manpower expenditures, and shorten the test time. The effect of trial time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

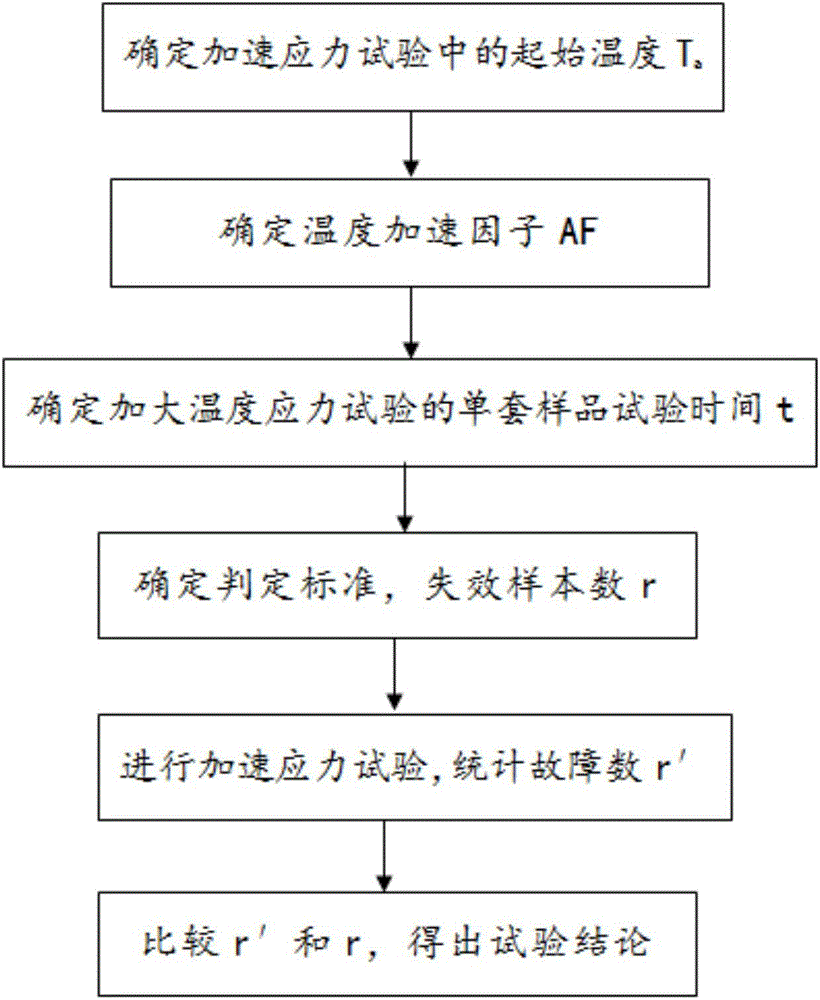

[0016] The present invention comprises the following steps:

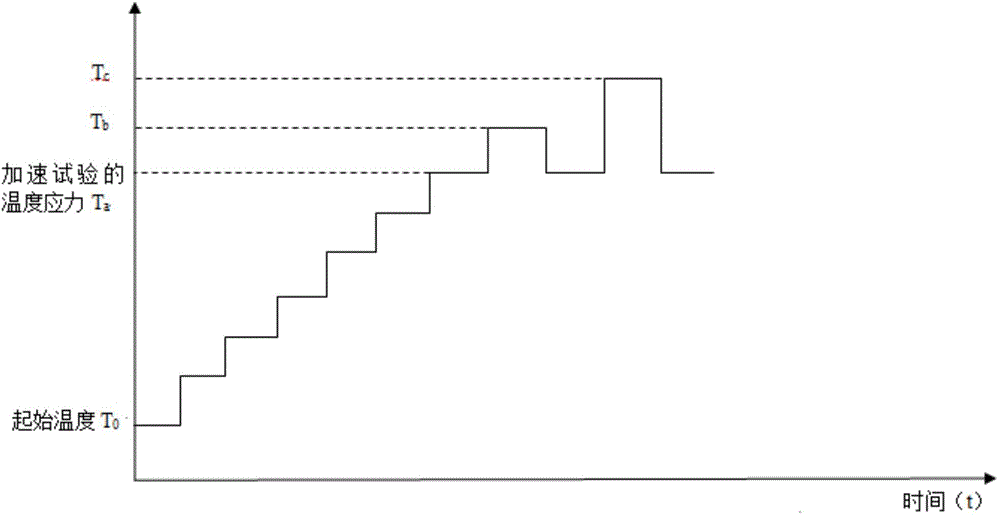

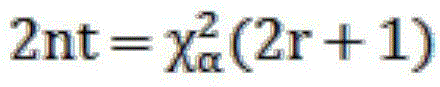

[0017] Step 1. Determine the initial temperature in the increased temperature stress test. Put a set of test samples into the high and low temperature box and power on, the temperature of the box is from T 0 start, T 0 It is the initial temperature of the reliability test specified in GJB 899A-2009, and the temperature is raised according to the step value of 5°C, and the next temperature point is reached. After 15 minutes of power-on, the test is carried out. If the test sample does not fail, continue to follow the 5 ℃ step value for temperature rise and power detection until the test sample fails, record the temperature value at this time, denoted as T b , record a temperature point as T a , restore the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com