Shoemaking vamp pressing machine

A technology for flattening machines and shoe uppers, which is applied in the direction of shoemaking machinery, applications, footwear, etc., and can solve problems such as labor and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

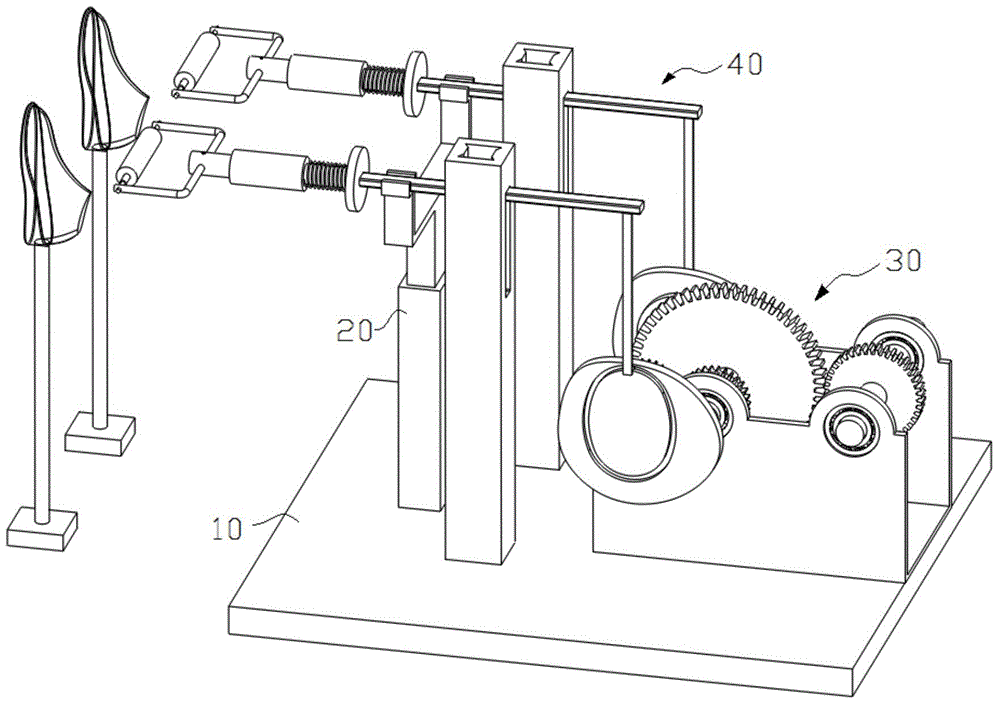

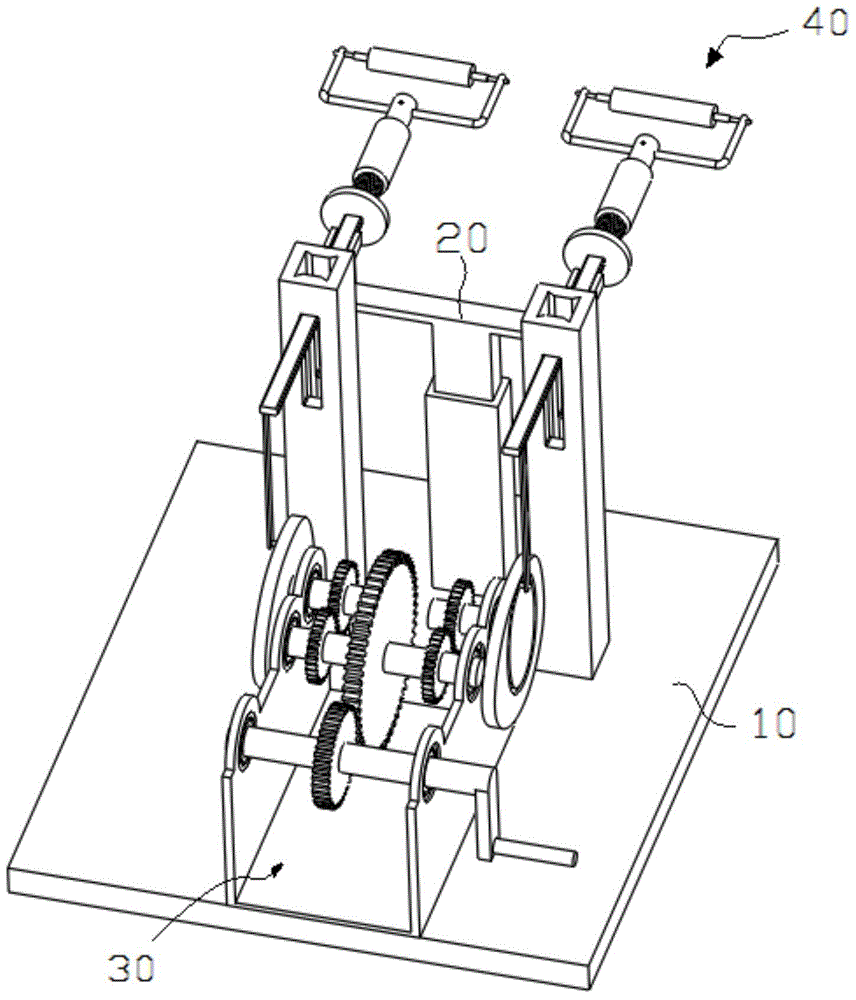

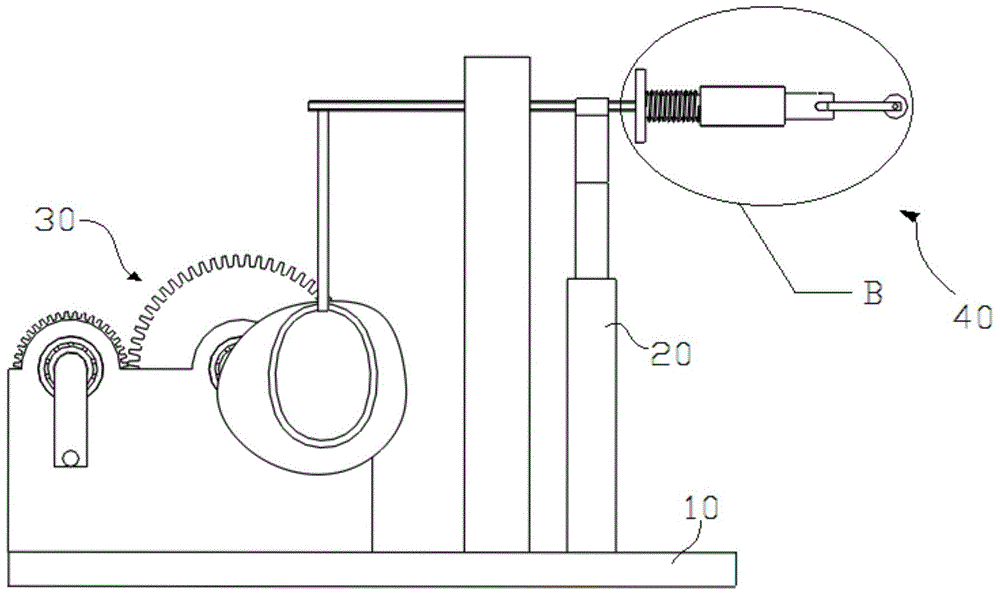

[0024] Such as figure 1 and Figure 7 , a shoe upper flattening machine for shoemaking, including a base 10, a support rod 20, a driving mechanism 30 and a flattening mechanism 40; the support rod 20, the flattening mechanism 40 and the driving mechanism 30 are all located on the base 10 , the flattening mechanism 40 is two sets of identical parts placed in parallel on both sides of the drive mechanism 30; the flattening mechanism 40 is vertically provided with a pillar 41, and the elevating rod 42 is installed through the pillar 41, and the elevating rod 42 is connected to the The grooved cam lever 35 of the driving mechanism 30 is connected to move up and down, and the flattening roller 47 is installed horizontally at the end of the flattening mechanism 40, and the flattening roller 47 is connected with the U-shaped rod 46, and one end of the lifting rod 42 can slide in the cylinder 44, and the cylinder The other end of 44 is connected to the U-shaped bar seat 45, and the U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com