A new type of sterilizer chain net conveying system

A technology of conveying system and sterilizer, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as easy deviation, machine failure, etc., achieve low failure rate, simple system structure, stable and efficient chain network conveying system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

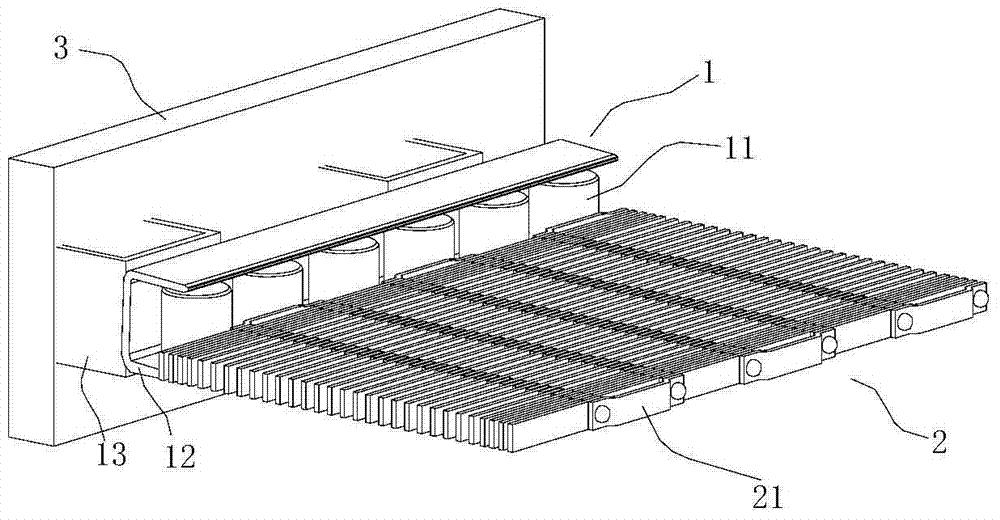

[0037] Such as figure 1 As shown, this embodiment discloses a new type of chain net conveying system for sterilizers. The system includes a chain net limit and anti-deviation device, which is used to dynamically correct the deviation of the chain net in operation and prevent the chain net from deviation during the conveying process. .

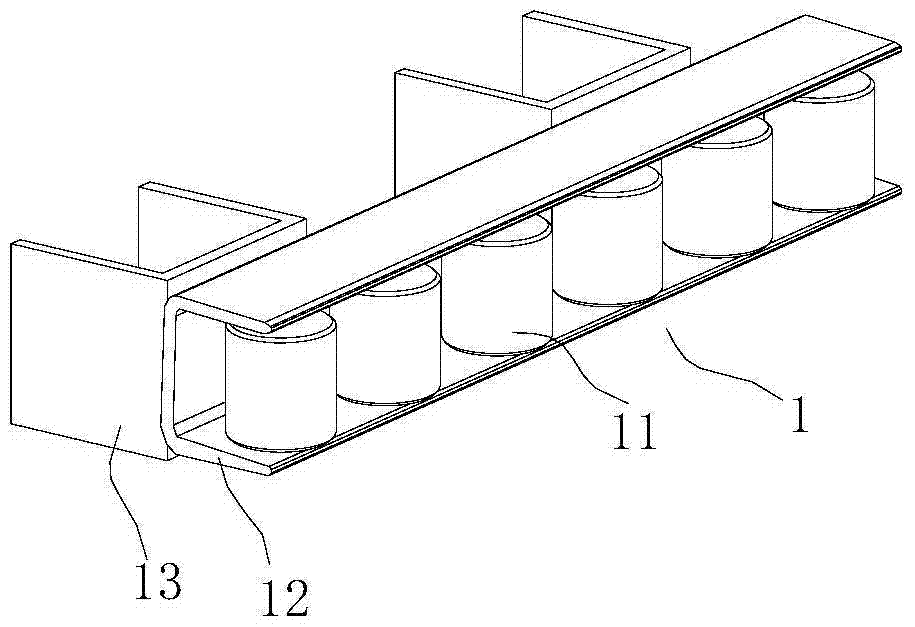

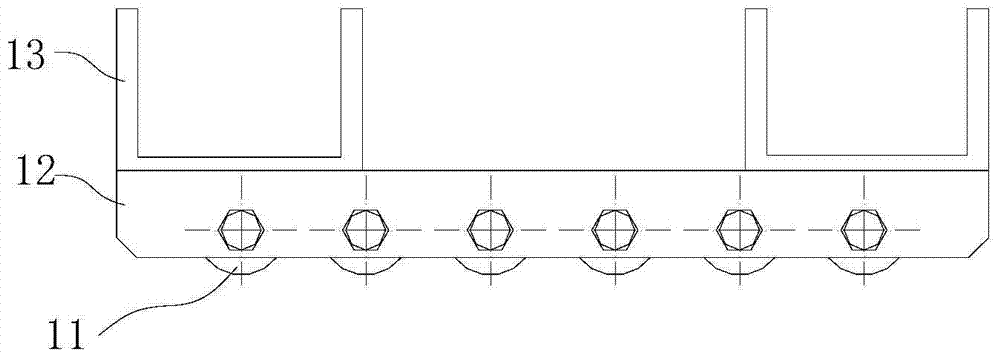

[0038] Such as figure 2 , 3 As shown, the chain net limit and anti-deviation device includes at least 10 sets of roller combination structures 1, wherein each set of roller combination structures 1 is spaced apart and installed on the side plate 3 of the sterilizer along the chain net conveying direction.

[0039] The roller combination structure 1 includes at least 6 rollers 11 combined side by side; the reason why the roller structure is adopted is that if a common plate-type limiting structure is adopted, although it can effectively prevent the chain net from running off in the forward conveying process , so that the chain network is tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com