Full-automatic tea making machine

A tea making machine and fully automatic technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of not knowing how many tea leaves to put, the taste of tea is not optimal, and the failure to realize automatic tea brewing, etc. The effect of Jiapin tea taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

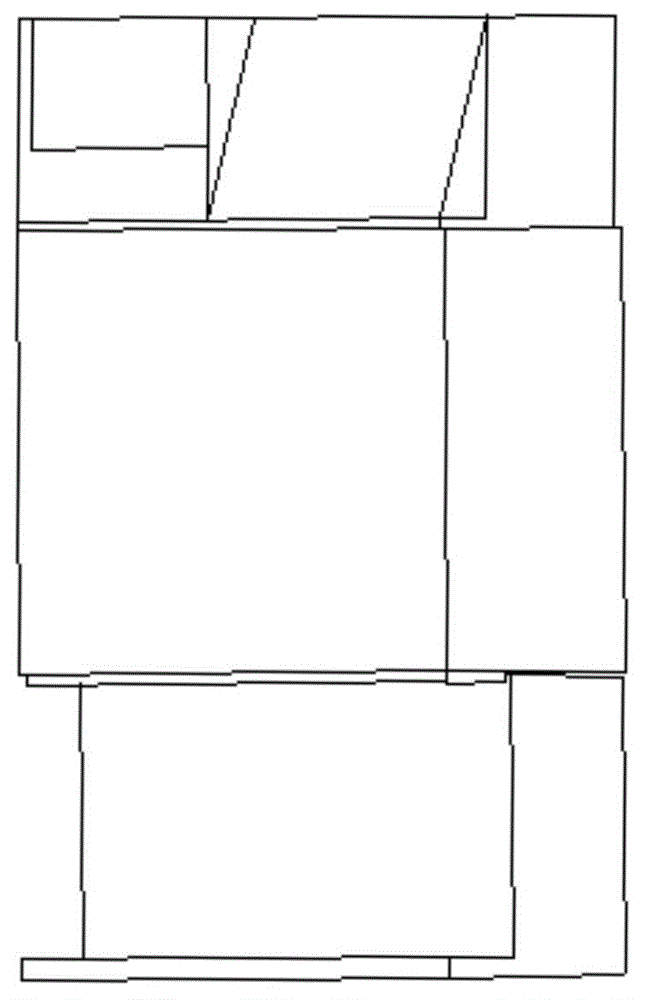

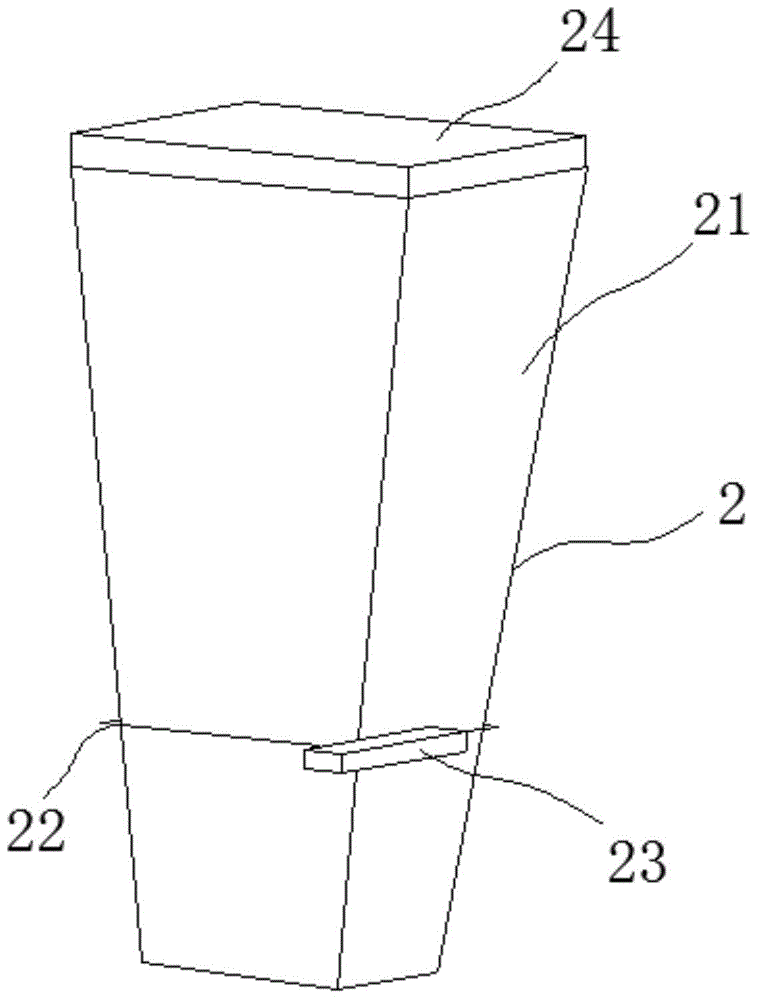

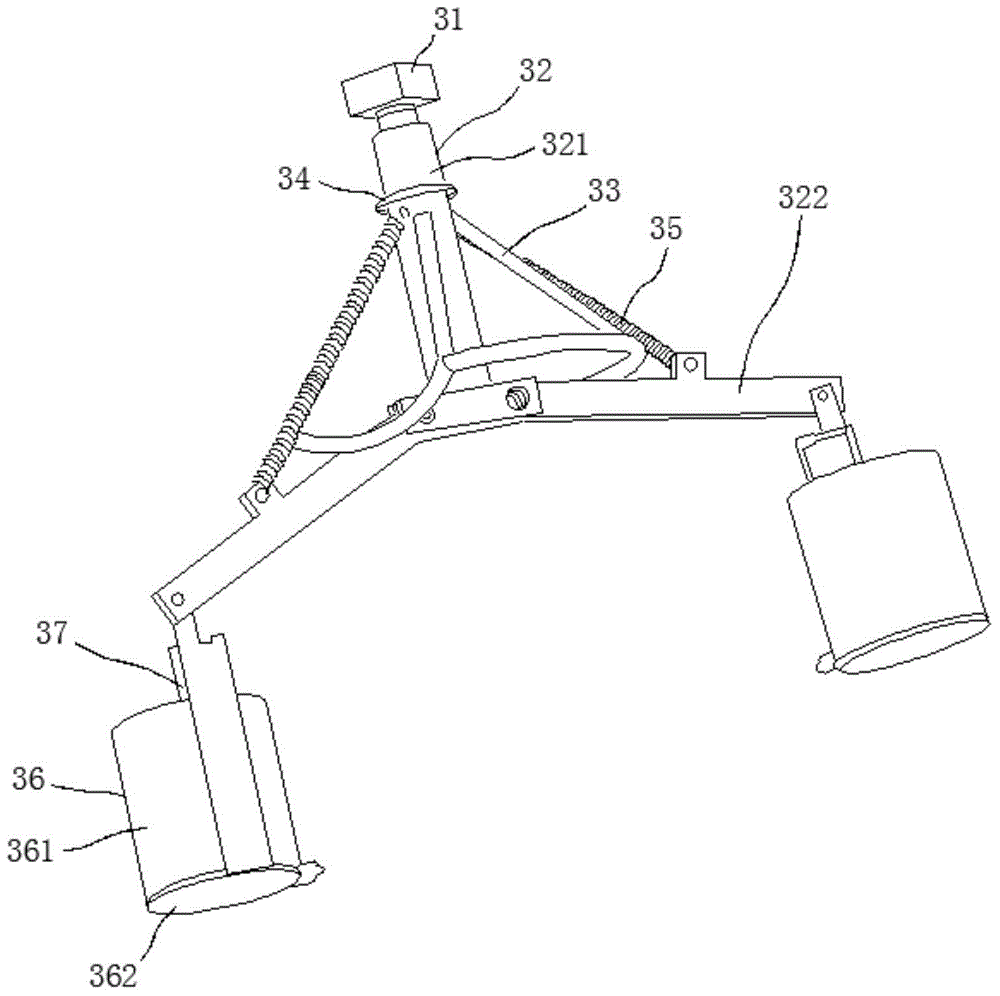

[0045] Such as Figure 1 to Figure 5 As shown, a fully automatic tea making machine includes a control module 1, a tea leaf fetching module 2, a tea set rotating module 3, a tea making module 4, a water supply module 5, a heating module 6 and a power supply module, the tea fetching module 2, the tea set The rotating module 3, the tea making module 4, the water supply module 5, the heating module 6 and the power supply module are all connected to the control module 1 through lines, the tea set rotating module 3 is placed under the tea leaf taking module 2, and the The tea module 4 is placed on one side of the tea set rotating module 3, the water supply module 5 is communicated with the tea making module 4 through pipelines, the heating module 6 is placed in the water supply module 5, and the tea taking module 2. The tea set rotation module 3 , the tea making module 4 , the water supply module 5 and the heating module 6 are all connected to the power supply module through lines....

Embodiment 2

[0061] A fully automatic tea making machine, its structure from top to bottom is a clean water storage tank 51, a heating tank 52, a tea set rotating module 3, a tea making container 41 and a waste water storage tank 7; the tea set rotating module 3 has a guide cup 36 guide rails with running tracks, the guide rails are fixed, relying on the stepper motor 31 to drive the cup 36 to rotate, when the cup 36 is at the lowest point of the running circle, stop running, start the process of washing tea and brewing tea, and reach the set After the time, continue to rotate the cup, break away from the tea container 41, and enter the cleaning area; in the cleaning area, first use cold water to rinse the cup, and after a certain time, turn it counterclockwise to the bottom of the heating box 52 for thermal disinfection; then continue clockwise Rotate to reach the middle of the clean water storage tank 51 and the tea inlet for cleaning and disinfection, and use a fan to air-dry the teacup ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com