Construction method of coal seam floor raft foundation

A technology of coal seam floor and construction method, which is applied in earth-moving drilling, surface mining, underground mining, etc., can solve the problems of unevenness, difficulty in dredging, and high pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

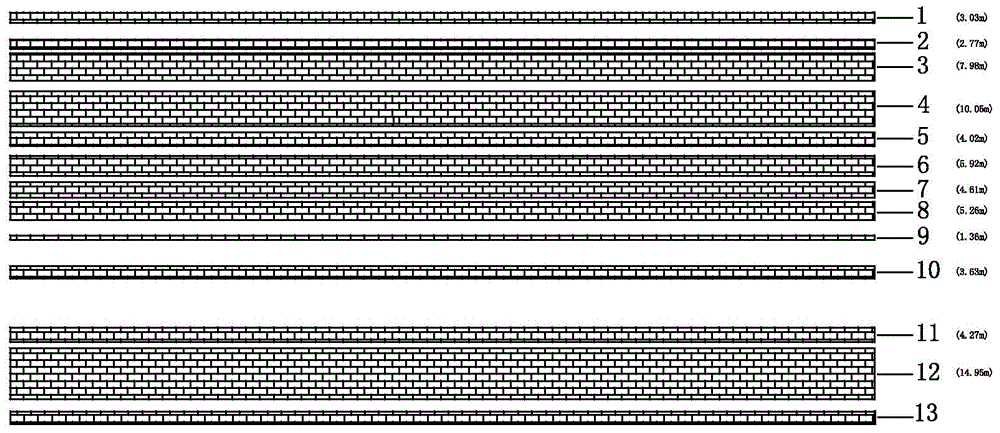

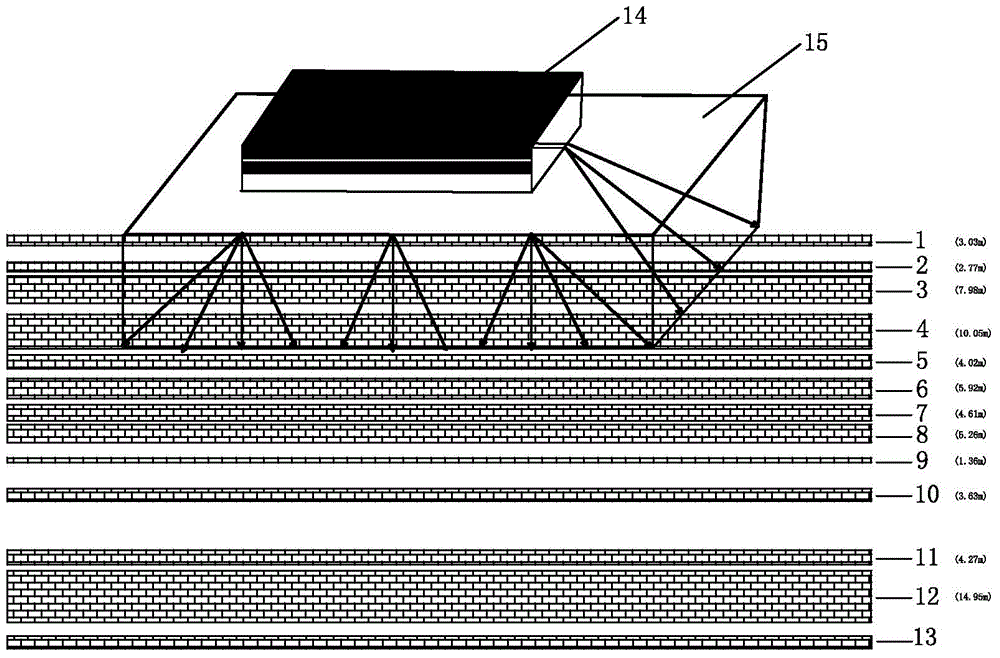

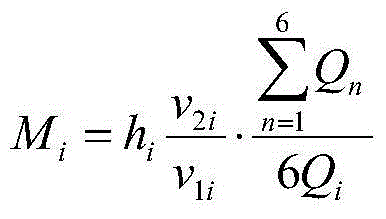

[0017] like Figure 1-2 As shown, the direct floor of coal seam 14 develops strata such as mudstone and sandstone. After the coal seam is mined, it loses its water-proof effect due to the impact of mining. Combination, the limestone stratum is divided into three sections: the upper section is the first layer of limestone 1, the second layer of limestone 2, the third layer of limestone 3 and the fourth layer of limestone 4, which is the main water-filled aquifer for coal seam mining, and the middle section is The fifth layer of limestone 5, the sixth layer of limestone 6, the seventh layer of limestone 7, the eighth layer of limestone 8, the ninth layer of limestone 9, and the tenth layer of limestone 10 are weak aquifers or relatively water-proof layer, the lower part is the eleventh layer of limestone 11, the twelfth layer of limestone 12 and the thirteenth layer of limestone 13, which are in parallel and unconformable contact with the underlying Austrian ash. The Austrian as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com