Wireless monitoring system of spinning frames

A wireless monitoring and spinning frame technology, applied in textiles and papermaking, etc., can solve the problems that workers cannot monitor the status of the alarm device at the same time, the length is long, and the time for the accident of broken yarns and yarns is delayed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

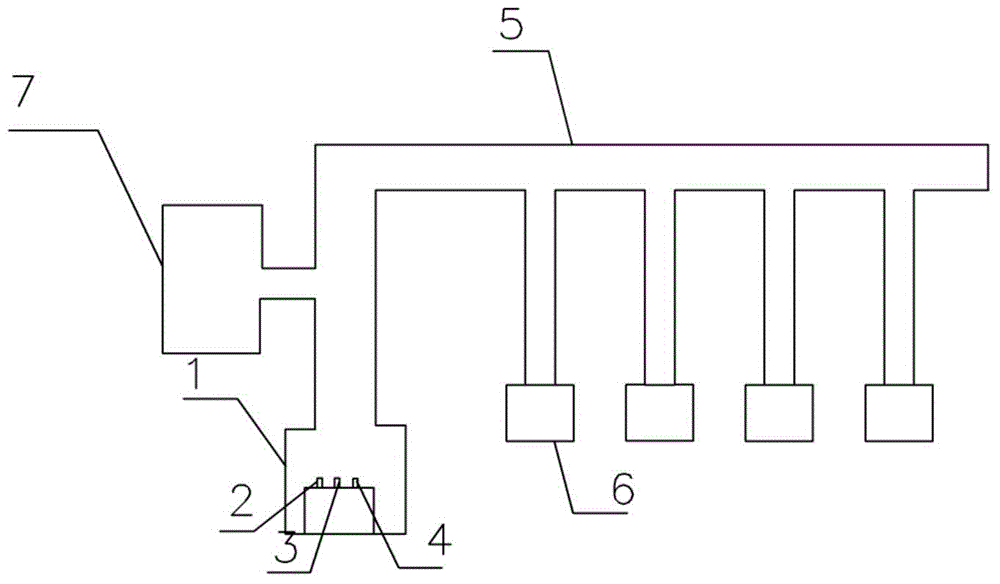

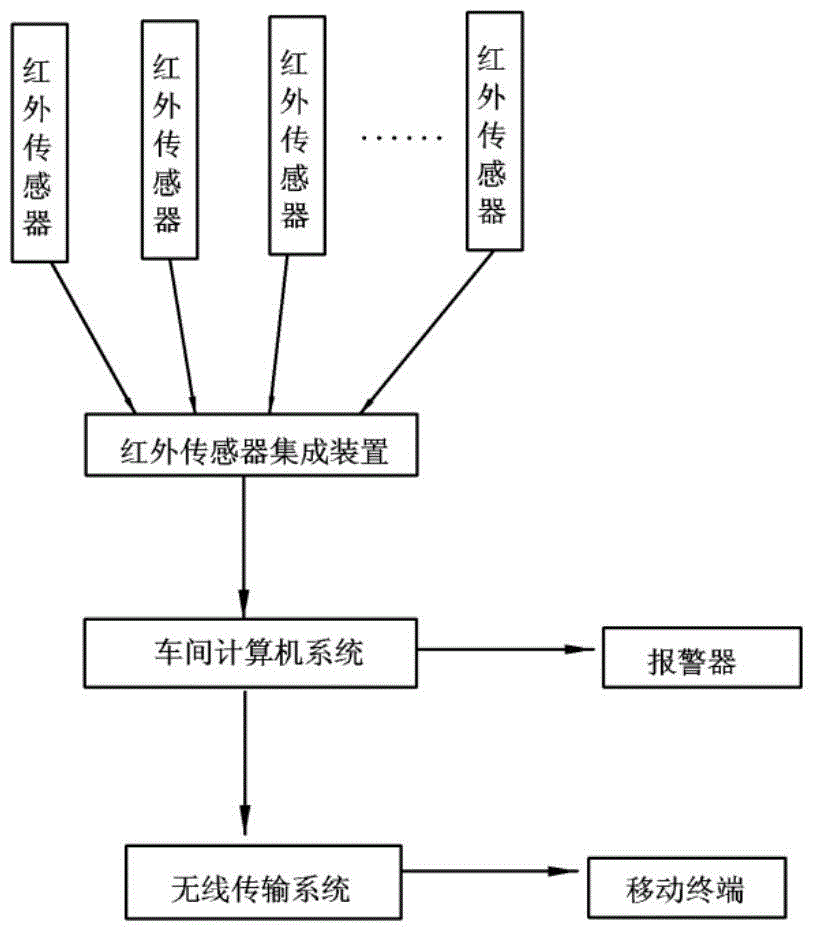

[0012] Such as figure 1 As shown, the present invention adopts the following technical solutions: the spinning frame wireless monitoring system includes an alarm device 1, an infrared sensor integration device 5, an infrared sensor 6, and a controller 7, and the alarm device 1 is provided with a red indicator light 2, a yellow indicator light 3, The blue indicator light 4 is an indicator light of three colors, the infrared sensor integration device 5 is connected to the controller 7, the controller 7 is connected to the alarm device 1, and the infrared sensor 6 is connected to the infrared sensor integration device 5.

[0013] The controller 7 includes a workshop computer system 8 and a wireless transmission system 9 .

[0014] The infrared sensors 6 are fixed on the spindles of the spinning frame, and each infrared sensor 6 is numbere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com