Combined door frame capable of being fast installed and installing method of combined door frame

An installation method and door frame technology, applied in the direction of window/door frame, etc., can solve the problems of complex production process, long time-consuming, poor versatility, etc., and achieve the effect of reducing the customization cycle, reducing cost, and strong adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

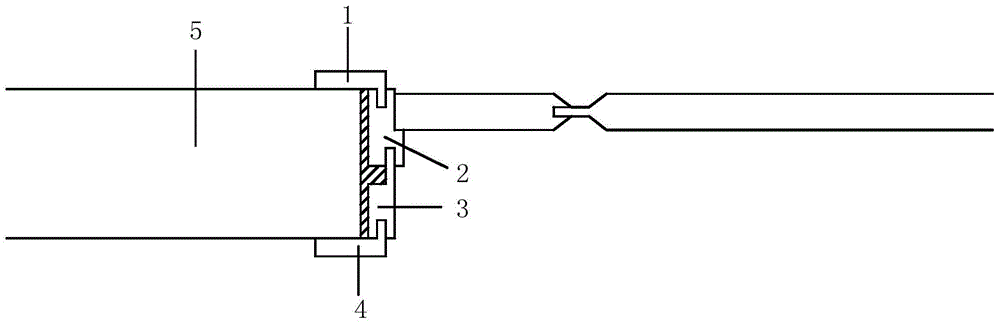

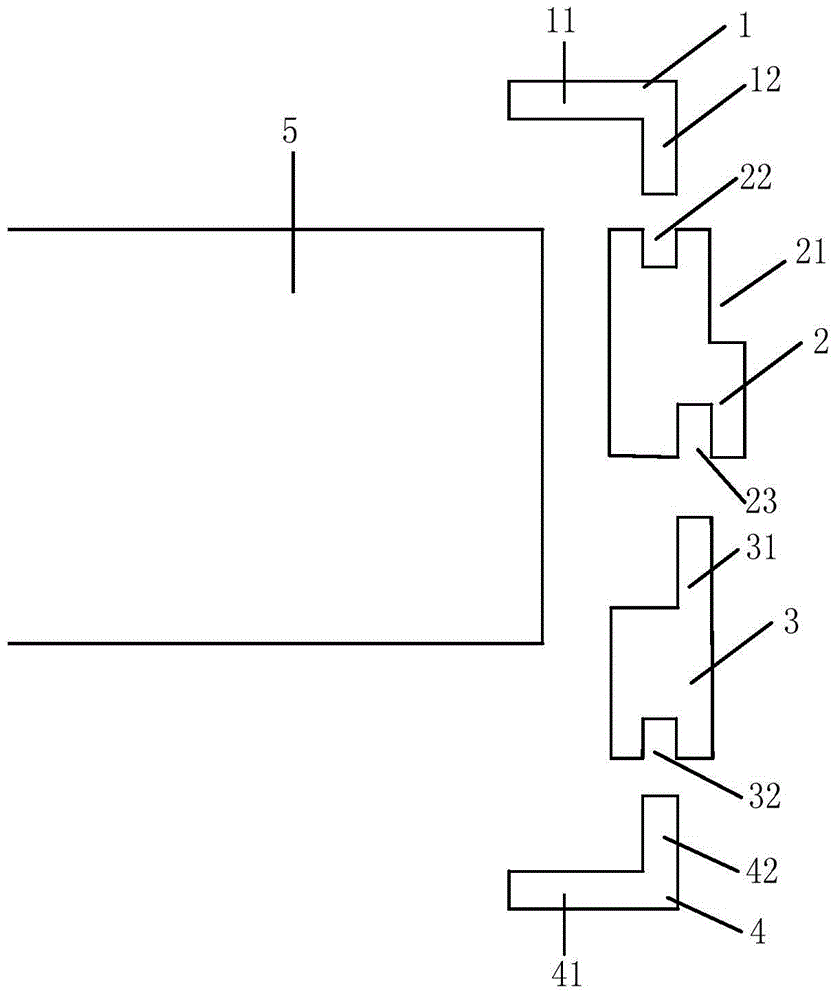

[0024] figure 1 A top view of the quick-installable combination door frame provided by the embodiment of the present invention. figure 2 A disassembled schematic diagram of a quick-installable combination door frame provided by an embodiment of the present invention. Such as figure 1 , 2 As shown, the quick-installable combination door frame provided by the embodiment of the present invention includes:

[0025] The first door trim 1, the first door cover 2, the second door cover 3 and the second door trim 4, wherein the first door trim 1, the first door cover 2, the second door Both the cover 3 and the second door trim 4 are elongated, and the first door trim 1, the first door cover 2, the second door cover 3 and the second door trim 4 The grooves and protrusions are sequentially mated and connected; the side 11 of the first door trim 1 away from the first door casing 2 and the side 11 of the second door trim 4 away from the second door casing 3 41 are respectively fixed...

Embodiment 2

[0033] This embodiment provides a method for installing a combined door frame, including:

[0034] Measure the thickness of body of wall 5;

[0035] According to the measured thickness of the body of wall 5, the appropriate width of the protrusion 31 of the second door pocket 3 is obtained;

[0036] Cut off part of the protrusion 31 in the second door pocket 3 to make it reach a suitable length;

[0037] After inserting the protrusion 31 of the second door cover 3 into the third groove 23 of the first door cover 2, fix the first door cover 2 and the second door cover 3 on the wall 5;

[0038] Insert the side 42 of the first door trim 1 close to the first door pocket 2 into the second groove 22 of the first door pocket 2, and insert the side 42 of the second door trim 4 close to the second door pocket 3 into the second groove 22. In the groove 32 of the second door cover 3;

[0039] The side 11 of the first door trim 1 away from the first door casing 2 and the side 41 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com