Connector and building assembly with same

A technology for connecting parts and components, which is used in the construction of advertising structures, exhibitions, and performances, can solve the problems of inconvenient assembly and disassembly of profile frames and surface materials, monotonous fixed surface form, and long customization cycle, so as to achieve convenient and fast connection and disassembly. , The effect of saving manpower, material and financial resources and reducing economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and specific embodiments:

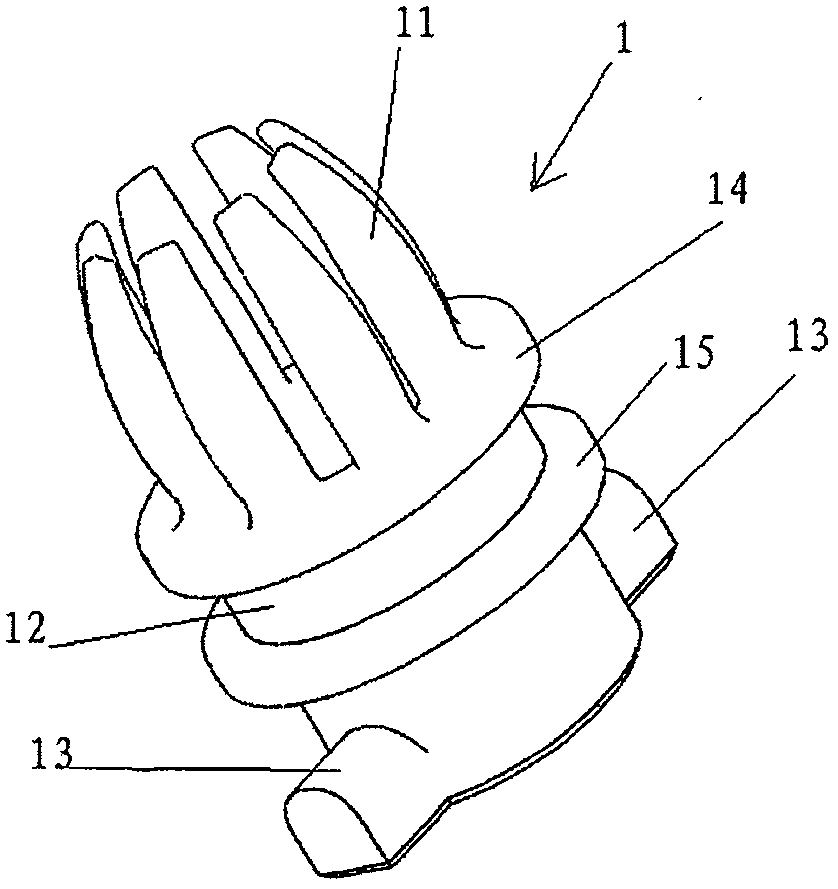

[0028] Reference figure 1 As shown, a connector 1 includes an elastic locking portion 11 and a plug-in rotating portion. The plug-in rotating portion includes a cylindrical portion 12, a stop portion 13, and a first ring portion 14 located on the periphery of the cylindrical portion. And the second ring portion 15, the cylindrical portion is a hollow cylinder, and the stop portion is two convex portions located on opposite sides of the outer cylindrical surface of the cylindrical portion and directly opposite. The elastic clamping portion includes eight elastic arc-shaped claw plates, the first ring portion is connected with the elastic clamping portion, and the stop portion, the second ring portion, and the first ring portion are sequentially spaced apart.

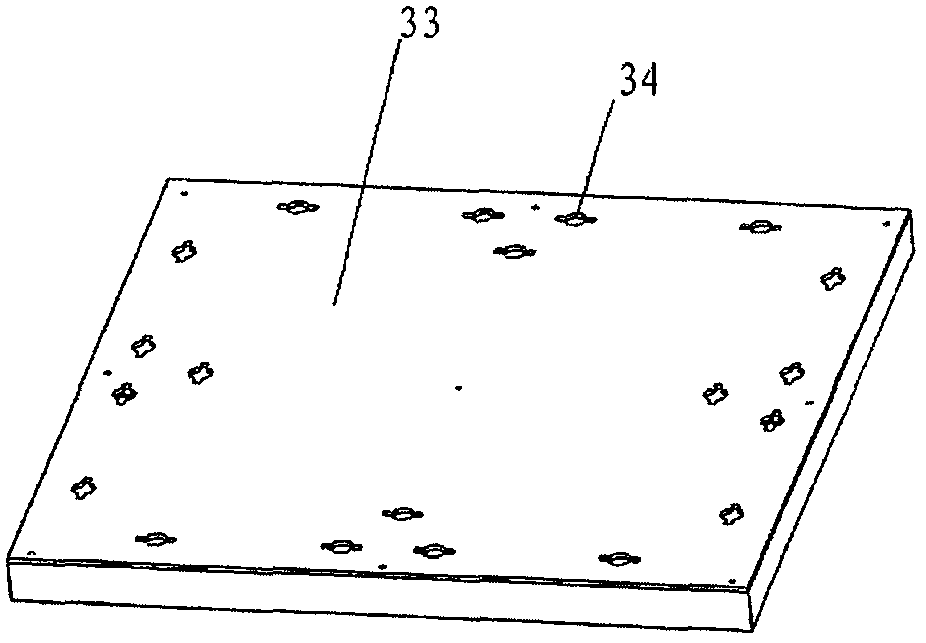

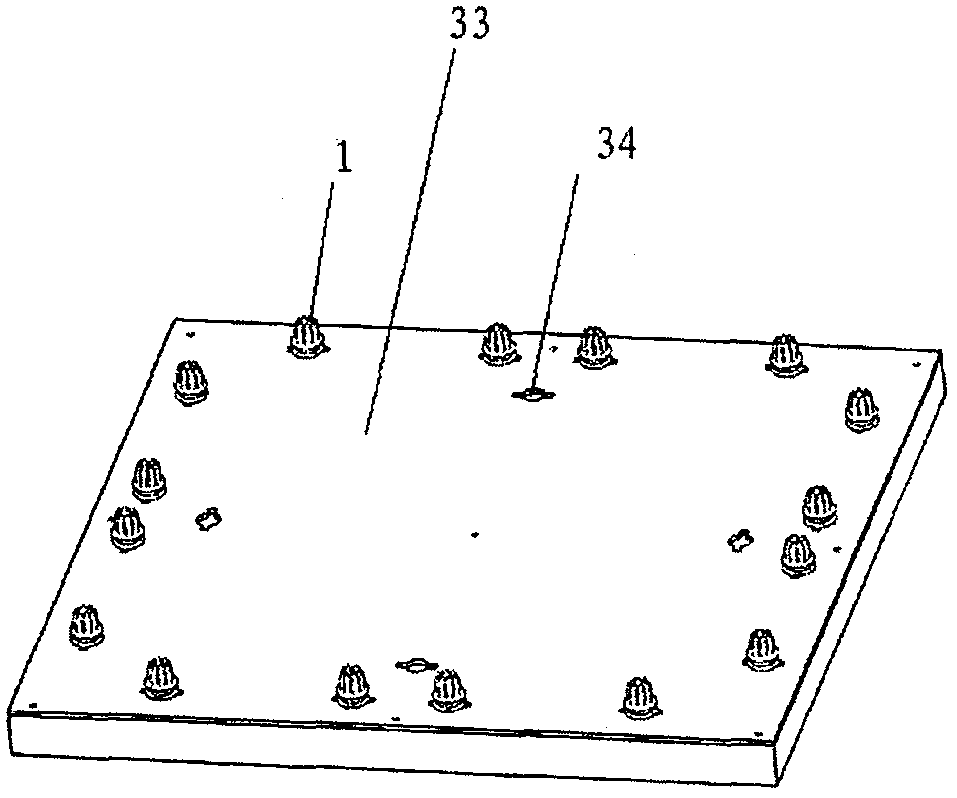

[0029] See Figure 2-5 , A building assembly, comprising a building profile 2, a face material 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com