Constructing module system

A technology of modular system and corner connectors, which is applied in the direction of display stands, display hangers, display shelves, etc., can solve the problems that cannot be reused, cannot achieve the construction goal, waste manpower, material and financial resources, etc., and achieve convenient connection and disassembly Fast, save manpower, material and financial resources, and reduce economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

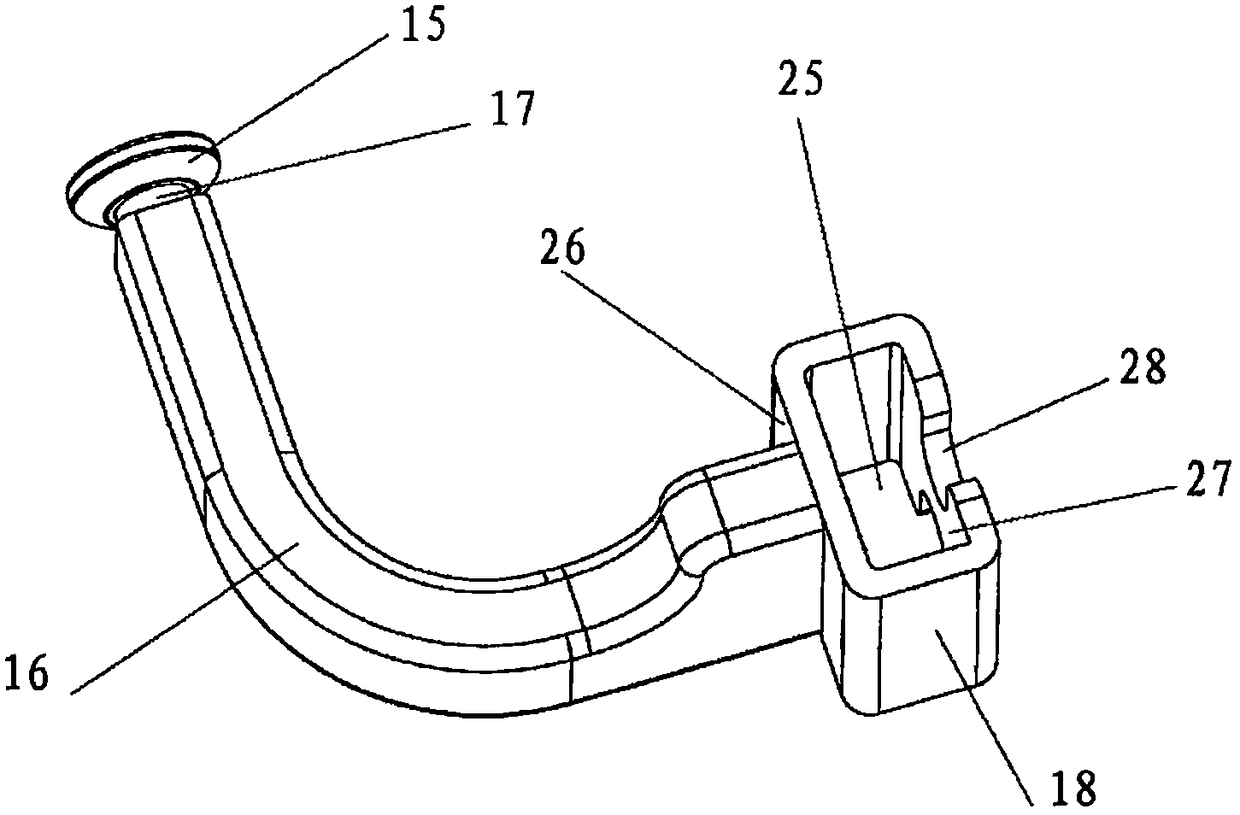

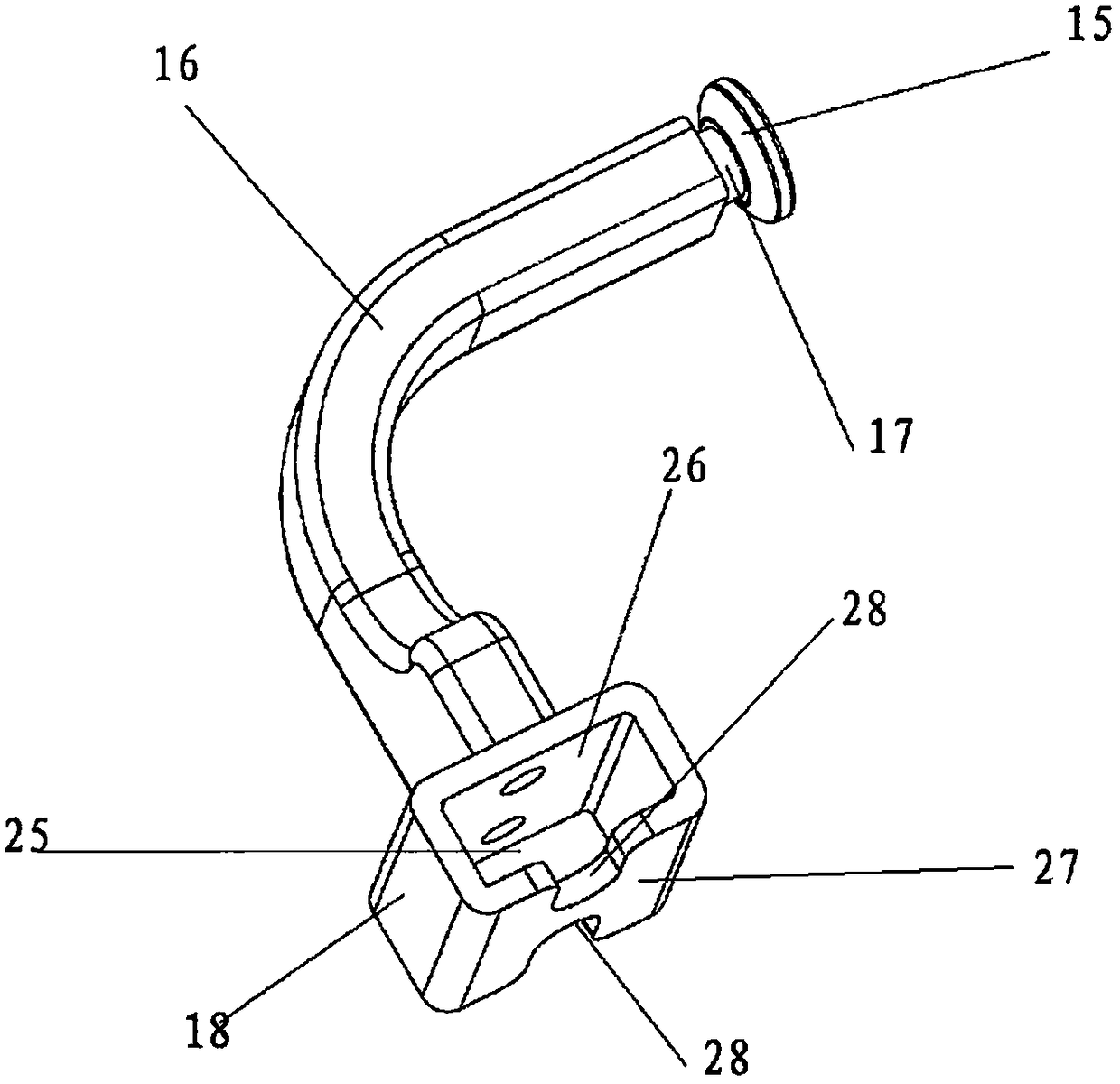

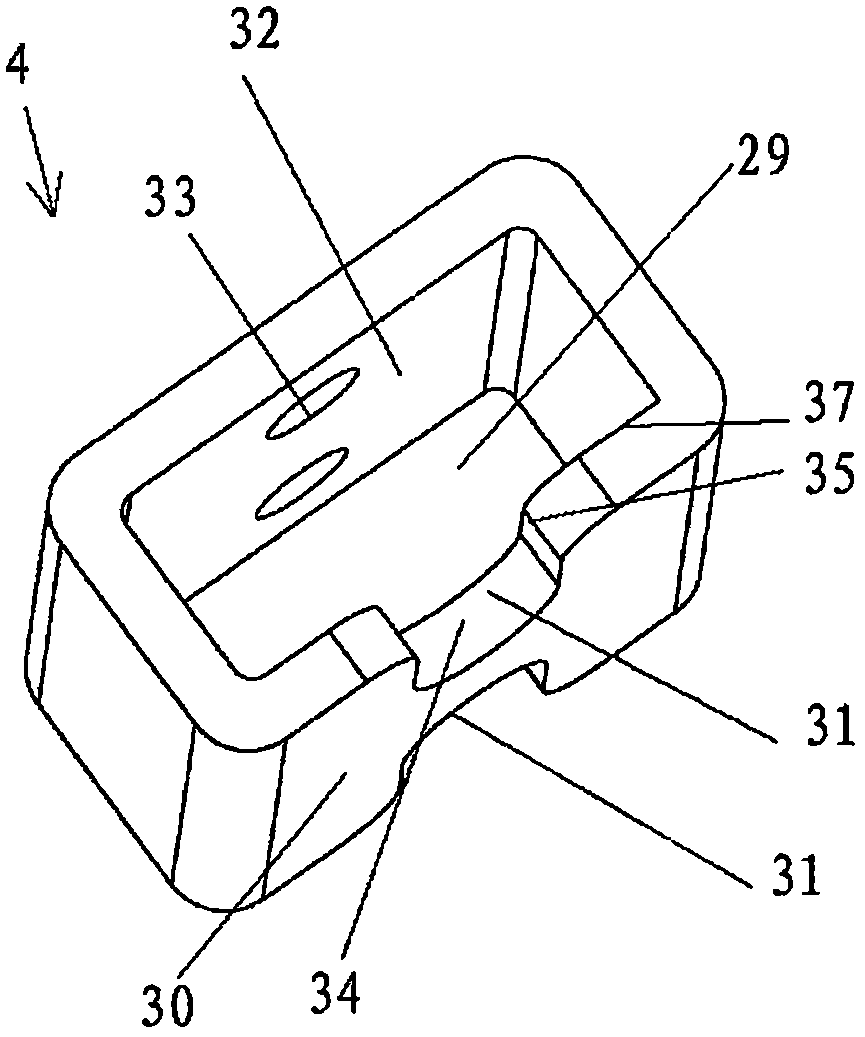

[0040] refer to Figure 1-13 As shown, a building module system is characterized in that: it includes a first building module 1, a second building module 2, and a corner connecting component, the first building module is connected with the second building module through a corner connecting component, and the first building module The corner connection is realized between the module and the second building module through the corner connection component. The corner connecting assembly includes: a first corner connecting piece 3 and a second corner connecting piece 4, and the first and second building modules are both composed of the same rectangular profile frame and cover decoration parts 5 fixed on both sides of the rectangular profile frame , the cover decoration part has been fixedly installed on the rectangular profile frame before the building m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com