Sectional material corner connecting assembly

A corner connector and corner connection technology, applied in the direction of connecting members, rod connections, mechanical equipment, etc., can solve the problems of long disassembly and assembly, inconvenient positioning of profiles at corners, large installation errors, etc., to save manpower, material and financial resources. , The connection and disassembly are convenient and quick, and the installation error is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

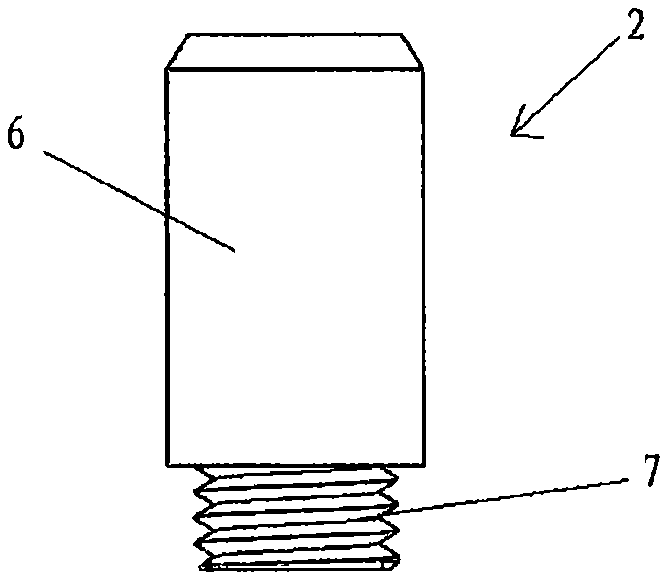

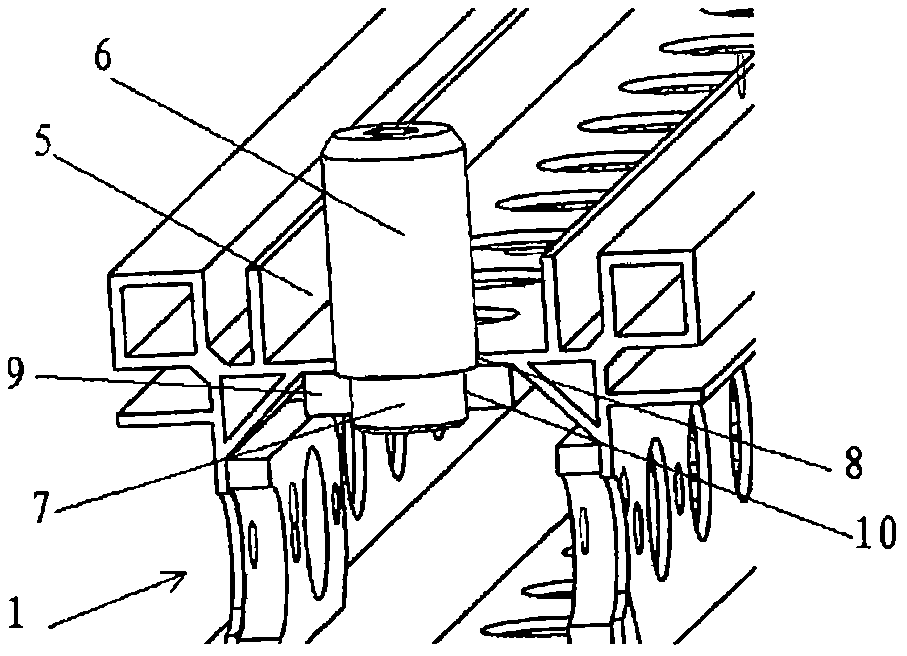

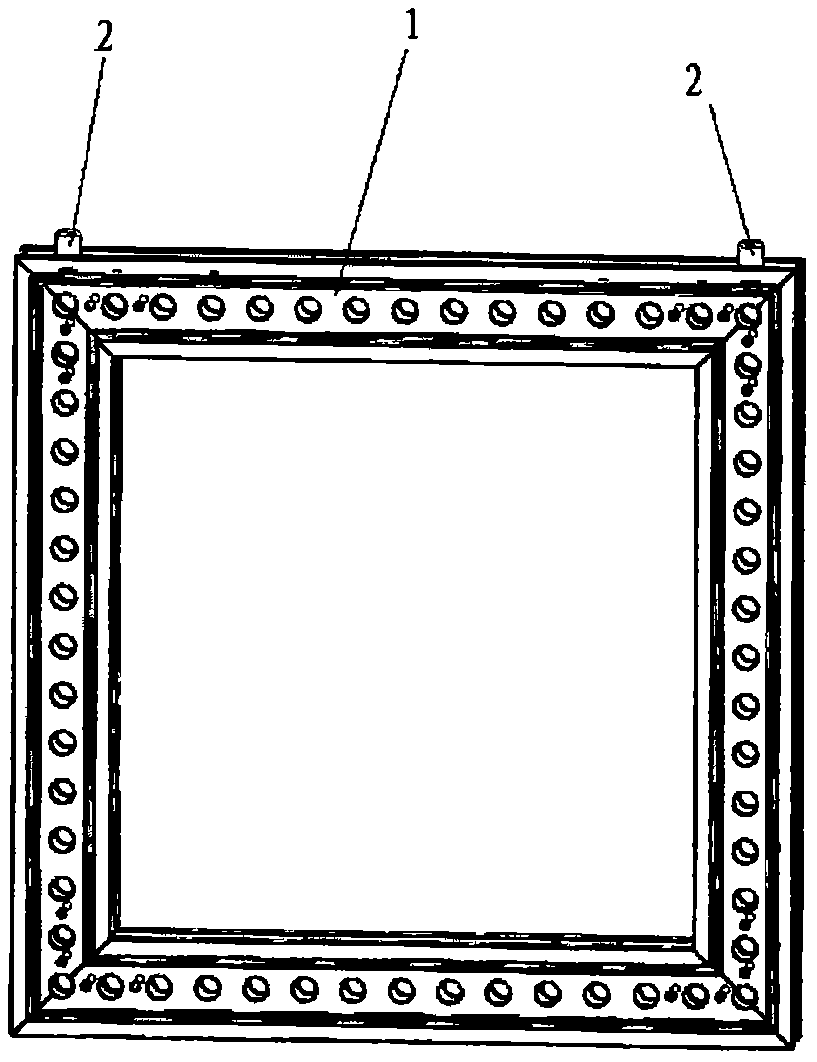

[0033] refer to Figure 1-6 As shown, a profile corner connection assembly includes a profile 1, a positioning pin 2, a T-shaped corner connector 3, the positioning pin is fixed on the profile, and a pin hole 4 is provided on the corner connector. The positioning pin is inserted into the pin hole. The surfaces of the profiles all have grooves 5 . The locating pin includes: an insertion pin 6 and a fixing pin 7; a fixing hole 8 is provided on the groove bottom of the groove of the profile, and a thickened plate 9 is arranged on the inside of the groove bottom of the groove of the profile, The thickened plate is provided with a threaded hole 10 , and the fixing pin is provided with threads (not shown), and the fixing pin passes through the fixing hole 8 and is threadedly connected with the threaded hole. A hole 11 is provided on the bottom of the groove of the profile adjacent to the profile, and a thickened plate 12 is provided on the inner side of the groove bottom of the ad...

Embodiment 2

[0035] see Figure 7-8 , the difference between the profile corner connection assembly in this embodiment and the profile corner connection assembly in Embodiment 1 is that the corner connection piece is an L-shaped connection piece, and in this embodiment, the two limbs of the L-shaped connection piece are chamfered at the corner. There is no first fixing hole at both ends of the corner connector.

Embodiment 3

[0037] see Figure 9 , The difference between the profile corner connection assembly in this embodiment and the profile corner connection assembly in Embodiment 2 is that: the two limbs of the L-shaped connector transition through the arc portion at the corner.

[0038] The advantages of the present invention are: 1) All parts of the assembly of the present invention are preferably made of metal, all parts can be recycled repeatedly, and the waste of forest resources is avoided, and the environmental protection is good.

[0039] 2) The connection and disassembly of the corner connection components is convenient and fast, saving manpower, material and financial resources.

[0040] 3) The corner connection components of the present invention are all standard parts, the customization cycle is greatly shortened, and the economic cost is greatly reduced.

[0041] 4) Through the positioning pin and the groove of the profile, the positioning of the profile at the corner is very conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com