Printing units for variable format offset presses

A printing unit, offset press technology, used in printing, printing presses, rotary presses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

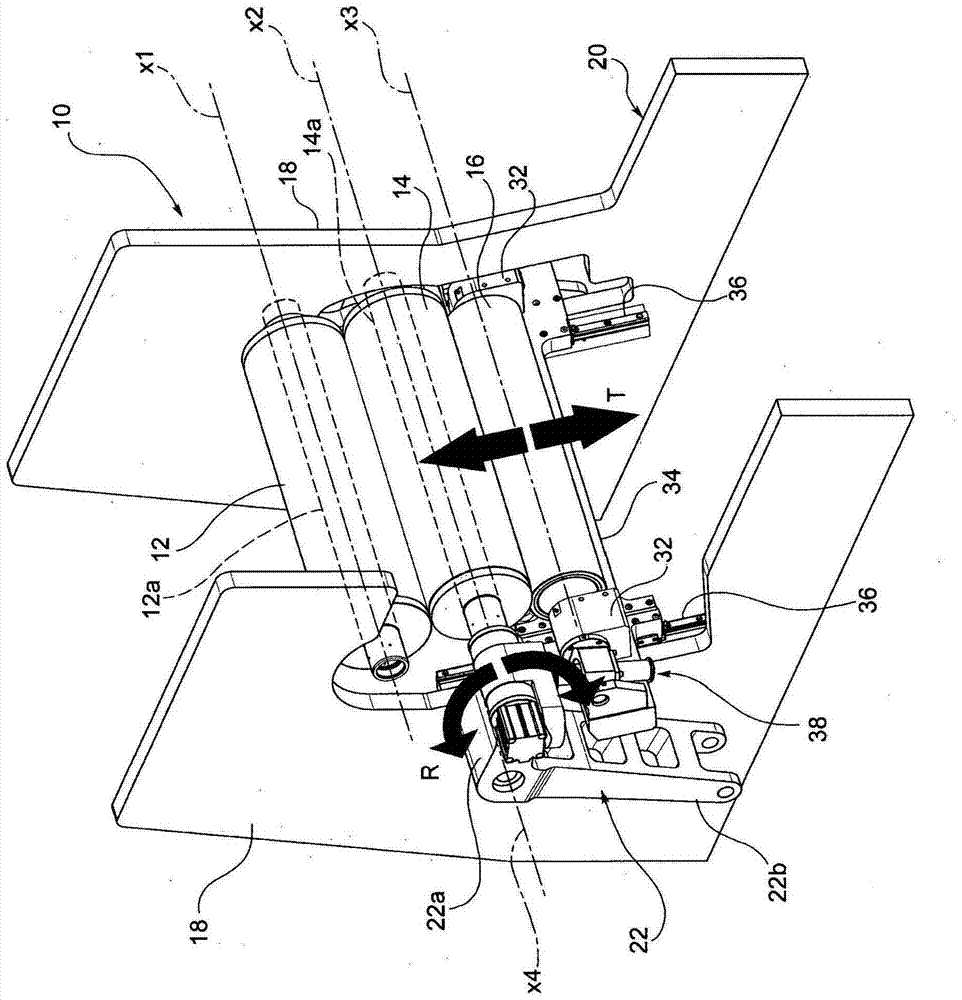

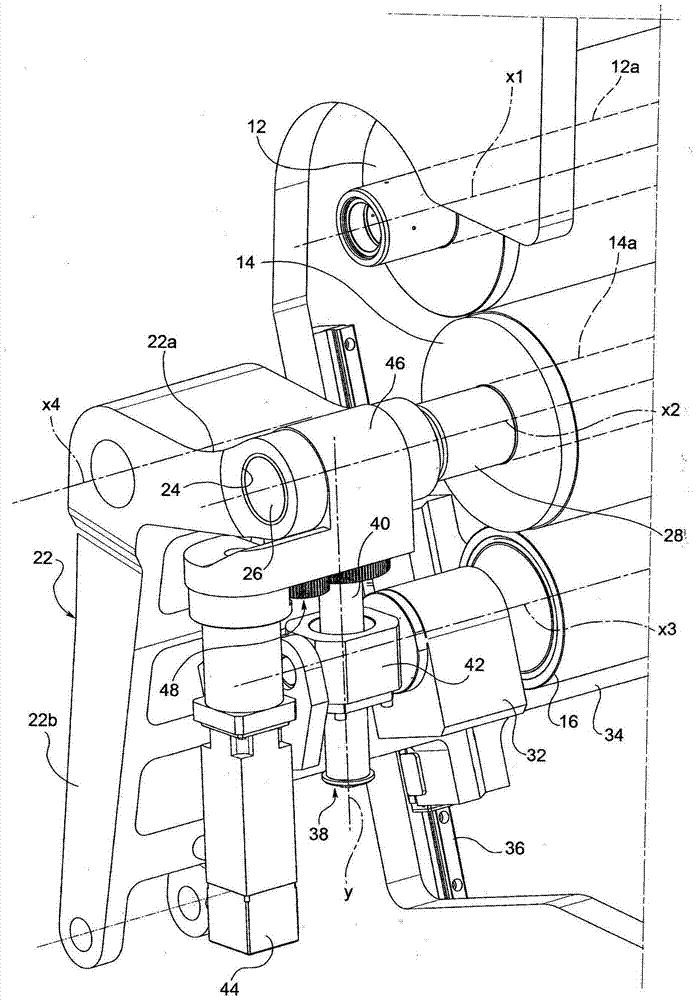

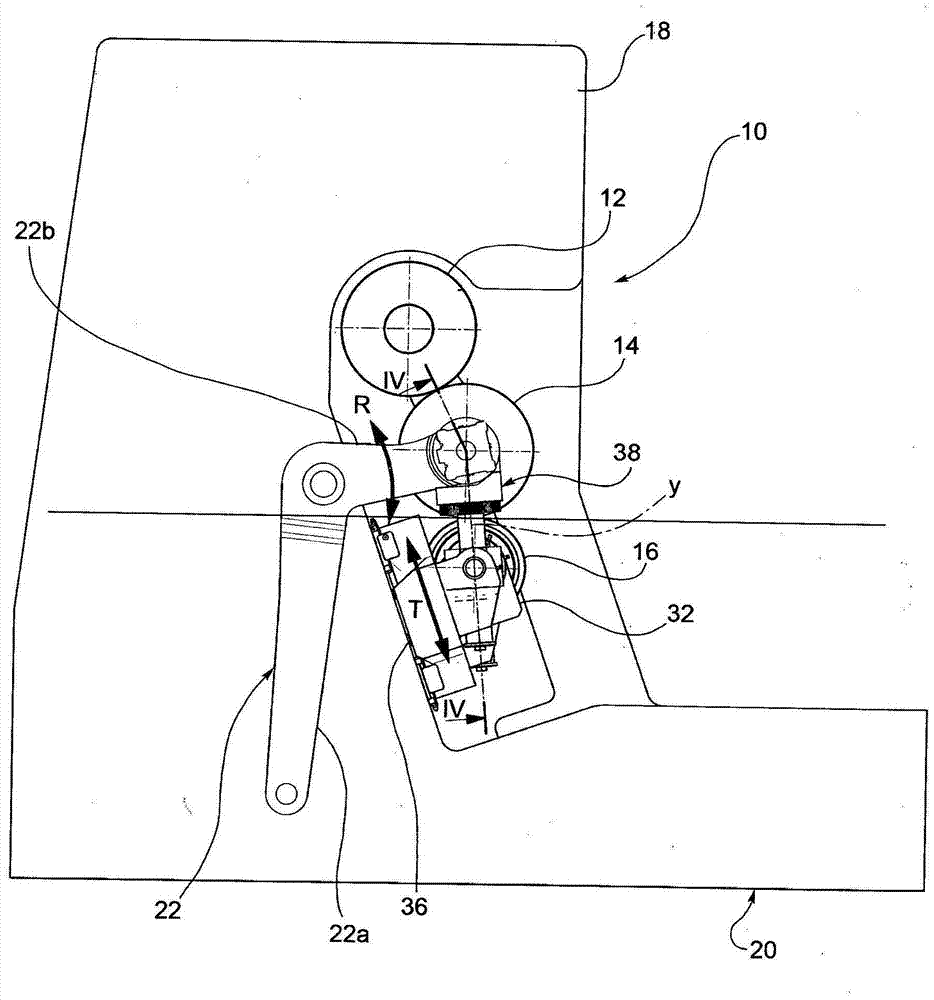

[0015] Referring to the drawings, reference numeral 10 generally denotes a printing unit to be used in a variable format offset press (hereinafter simply referred to as a printing unit), and only components important to the present invention are shown.

[0016] The printing unit 10 initially comprises three rotating cylinders, namely a plate cylinder 12 , an intermediate cylinder 14 and an impression cylinder 16 , wherein the axes of the three rotating cylinders are designated x1 , x2 and x3 respectively and are oriented horizontally. In the proposed embodiment, the plate cylinder 12 and the intermediate cylinder 14 form a printing format and can therefore be replaced by cylinders of different diameters, which are constructed as sleeves (i.e. hollow cylinders) and are respectively fitted in on intermediate support shafts 12a and 14a. In this way, when the printing format is to be changed, it is only necessary to remove the plate cylinder and the intermediate cylinder from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com