Creel loading and relieving device for a winding device of a textile machine producing crosswound bobbins

一种交叉卷绕筒子、减载装置的技术,应用在运输和包装、薄料处理、运送细丝状材料等方向,能够解决筒子架加载和减载装置复杂、功能不完全令人信服、昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

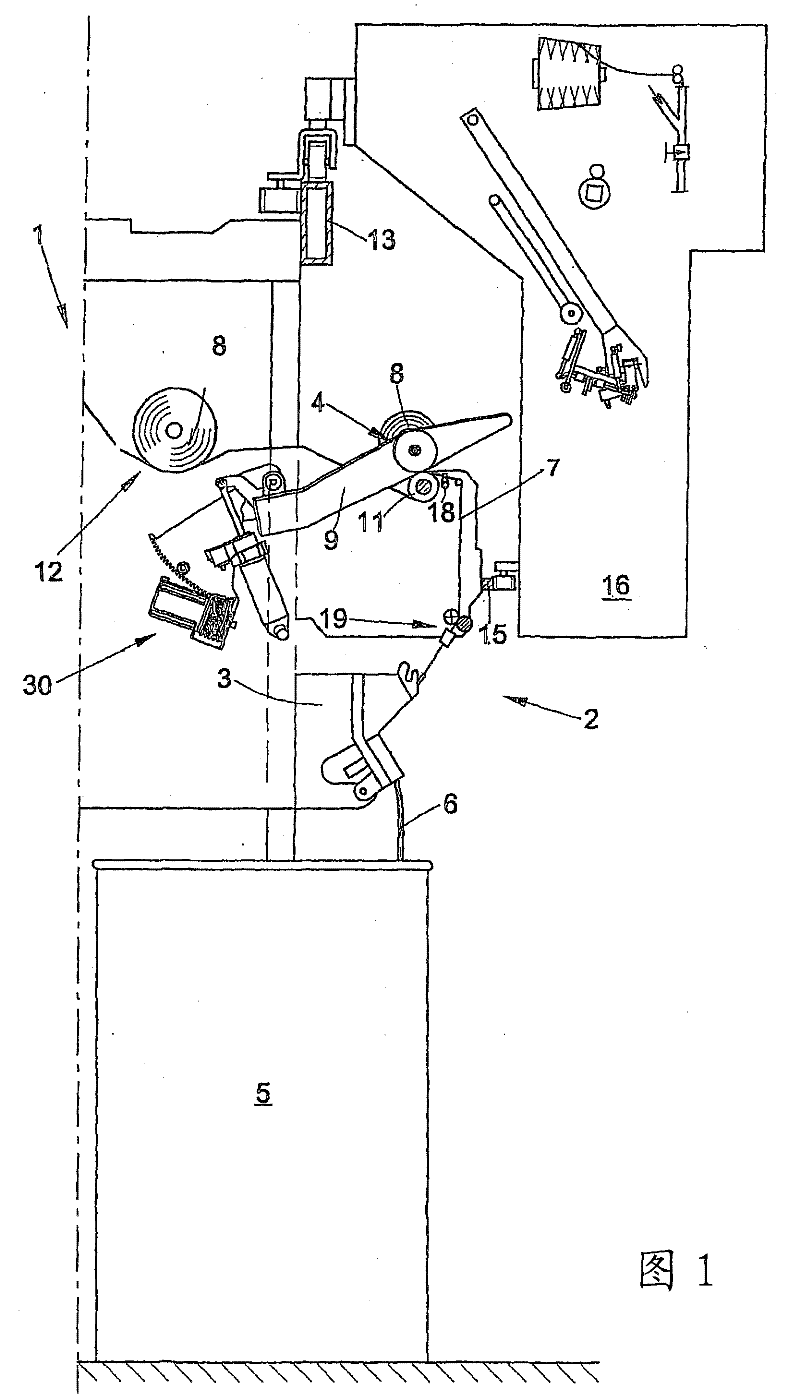

[0029] figure 1 A half of a textile machine (in this example an open-end rotor spinning machine) producing cross-wound bobbins is shown in FIG. As is known, such an open-end rotor spinning machine has a large number of similar workstations 2 arranged next to each other in the longitudinal direction of the machine. In this case, the workstation 2 has a spinning device 3 and a winding device 4 . The fiber strip 6 present in the spinning drum 5 is spun into a yarn 7 in the spinning device 3 , which is then wound up on the winding device 4 to form a cross-wound bobbin 8 .

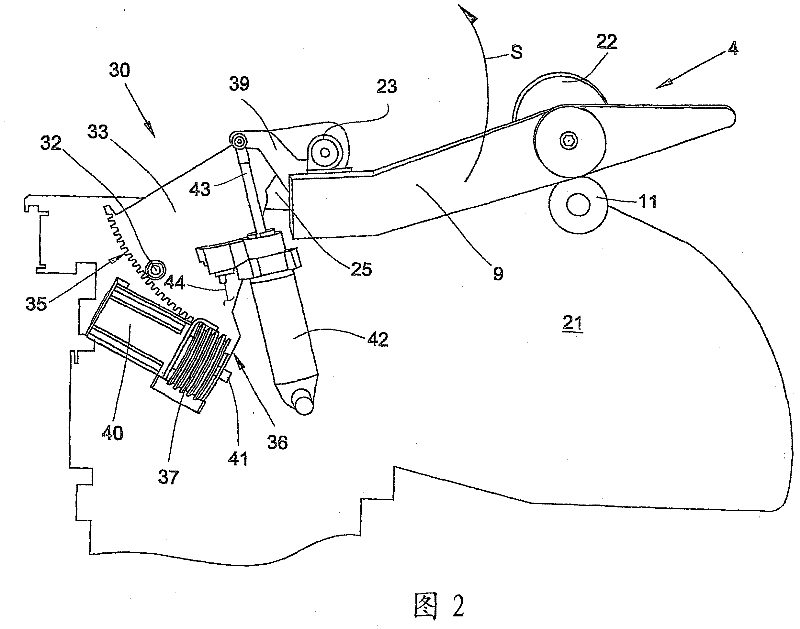

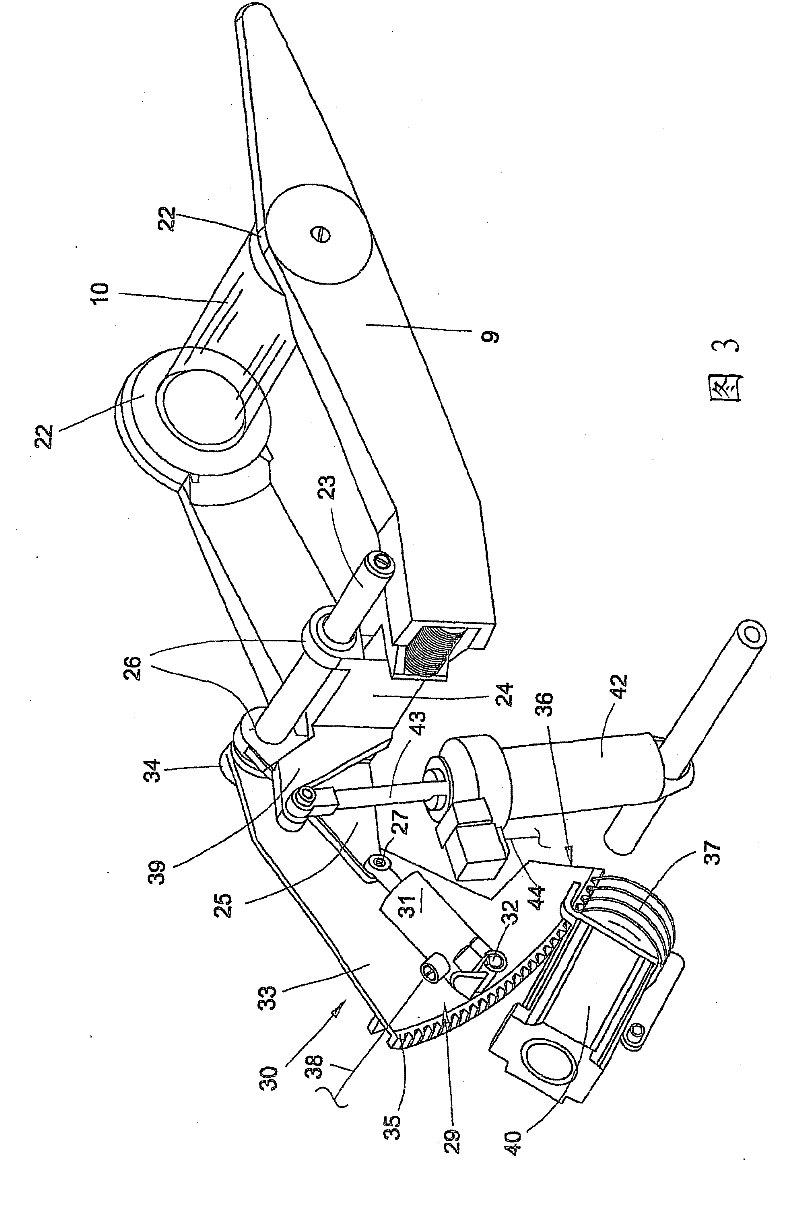

[0030] Such as figure 1 shown, and as follows with the help of figure 2 with image 3 Described in more detail, the winding device 4 is in each case equipped with a creel 9 which is acted upon by a loading and unloading device 30 . Empty tubes 10 or cross-wound bobbins 8 are rotatably mounted in the creel 9 and driven by means of drive rollers 11 in a frictional engagement. Furthermore, such a workstatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com