A high-lift percussion pump

A high-lift, plunger pump technology, used in pumps, piston pumps, liquid variable-capacity machines, etc., can solve the problems of simple structure, not high enough lift, low water energy utilization rate, etc. The effect of increasing the lift height and impact frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

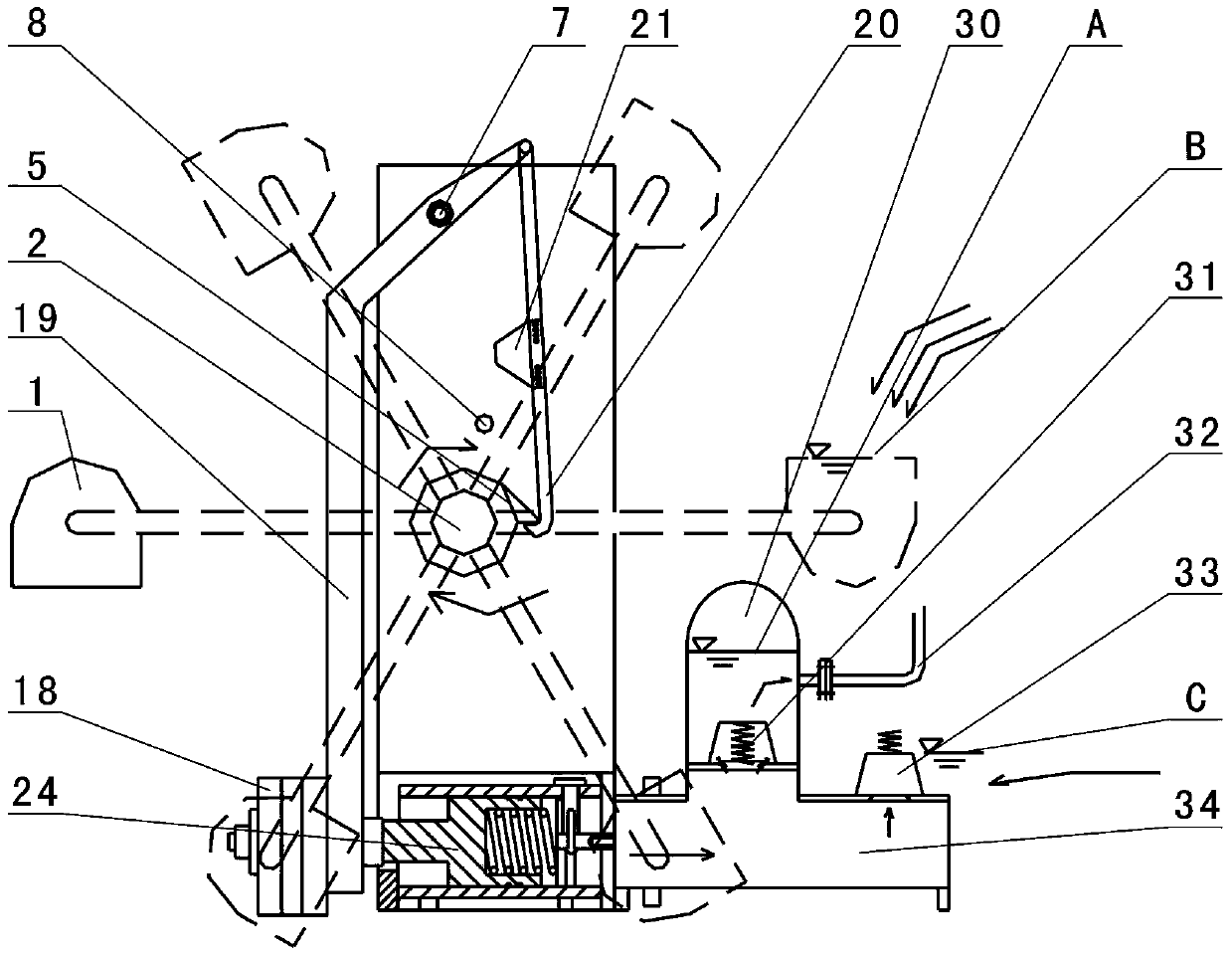

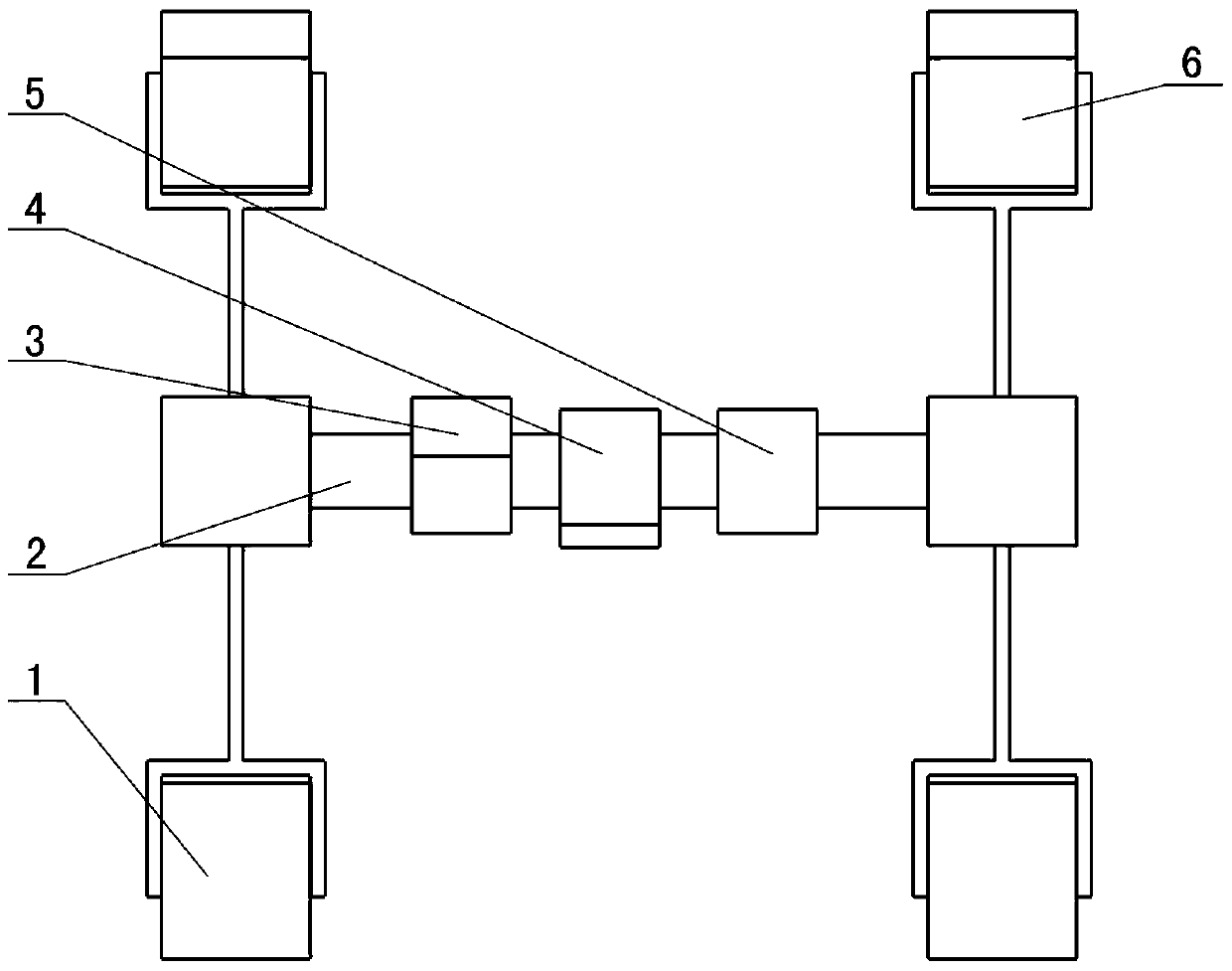

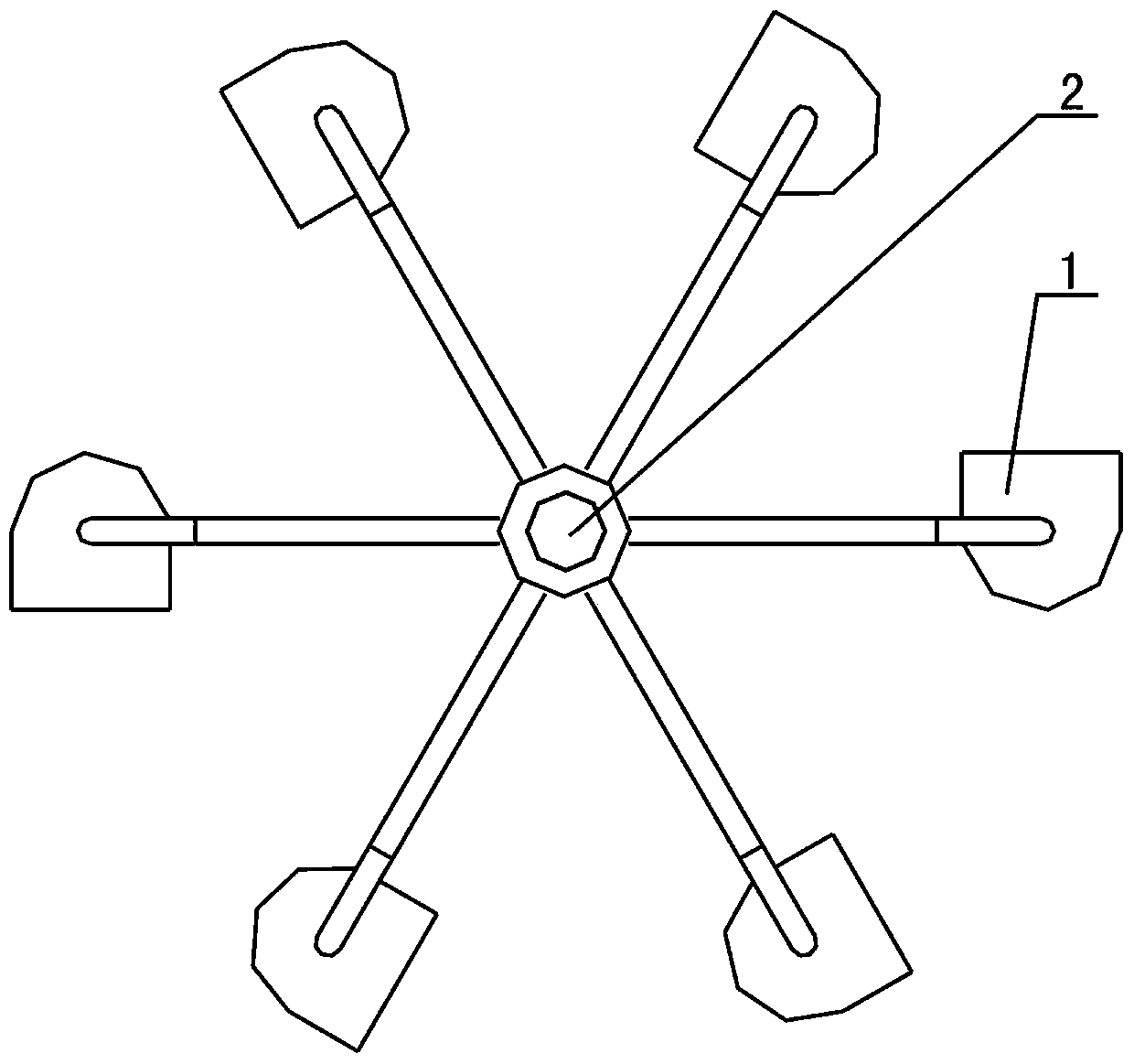

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] Such as Figure 1-Figure 8 As shown, the high-lift impact pump of the present invention includes a frame 9, a pressure cylinder 30, a first plunger pump 22, a second plunger pump 23, a third plunger pump 24, a first bucket group 1, a first Two bucket group 6, drive shaft 2, first single row gear 3, second single row gear 4, third single row gear 5, one energy storage shaft 7, first energy storage arm 10, second energy storage arm 14, third Energy storage arm 19, the first energy storage hammer 11, the second energy storage hammer 15, the third energy storage hammer 18, the first grapple 13, the second grapple 16 and the third grapple 20, three plunger pumps, Three single-row gears, three energy-storage arms, three energy-storage hammers and three grapples correspond to each other one by one. The first plunger pump 22, the second plunger pump 23 and the third plunger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com