A polishing device for inner spiral raceways of multiple screw nuts

A technology of screw nut and polishing device, which is applied in the field of precision polishing equipment, can solve the problems of small pores and low processing efficiency of the grinding wheel, and achieve the effects of easy replacement operation, improved friction efficiency, and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

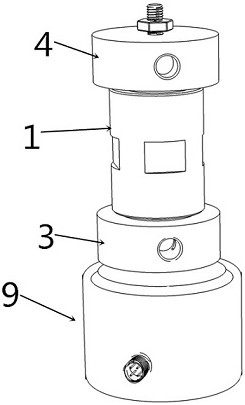

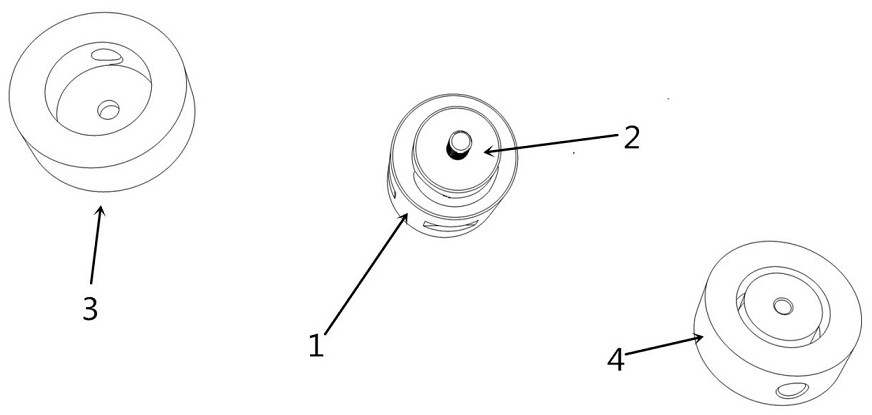

[0061] like figure 1 and figure 2 As shown, a polishing device for the inner spiral raceway of a single screw nut includes: a cylindrical center rod 2, the outer diameter of the center rod 2 is the same as the inner diameter of the screw nut 1, and the axis of the center rod 2 is consistent with the inner diameter of the screw nut 1. The axial length is greater than the axial length of the screw nut 1; the center rod 2 is arranged in the inner hole of the screw nut 1, so that part of the outer surface of the center rod 2 and the inner helical raceway A grinding pipe with only two ends open is formed; the base 3, corresponding to the position of the end of the grinding pipe, is provided with a second abrasive inlet and outlet for the abrasive to enter and exit; the top cover 4, corresponding to the position of the end of the grinding pipe, set There is a first abrasive inlet and outlet for abrasives to enter and exit; the connecting mechanism connects and fixes the center rod...

Embodiment 2

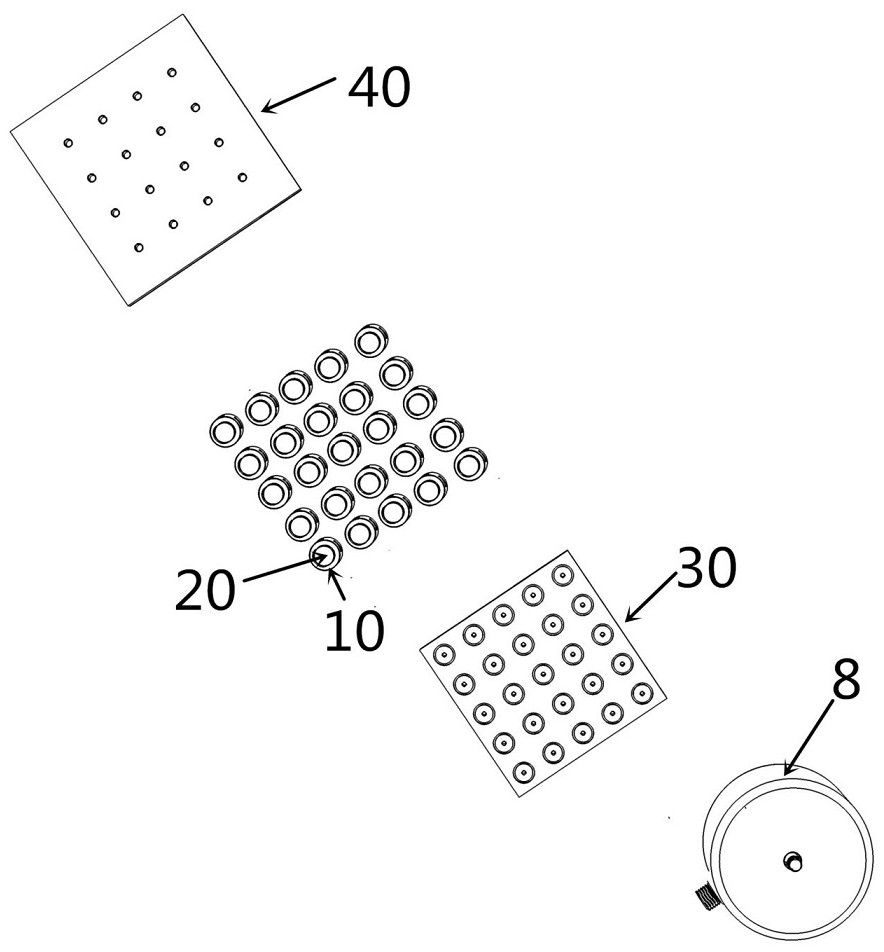

[0074] like Figure 3-8 As shown, a polishing device for the inner spiral raceway of a plurality of screw nuts includes: a central rod 20 is arranged in the inner hole of the screw nut 10, the central rod 20 and the screw nut 10 are one-to-one Correspondingly, a part of the outer surface of the central rod 20 and the inner spiral raceway form a grinding pipe with only two ends open; the top cover 40 is sleeved on the tops of the plurality of central rods 20, The cover 40 is provided with a plurality of first abrasive inlets and openings that communicate with each of the grinding pipes; the base 30 is located below the central rod 20, and the base 40 is provided with a plurality of first abrasive pipes that communicate with each of the grinding pipes Import and export of the second abrasive;

[0075] The top cover 40, the center rod 20, the screw nut 10 and the top cover are used for cooperative connection to form an integral structure;

[0076] The vibrating device 8 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com