A method for steel ring fault self-identification

A self-identification, steel ring technology, applied in the direction of measuring devices, instruments, mechanical parts testing, etc., can solve the problems of product off-line, low efficiency, high labor intensity, etc., to reduce error rate, ensure accuracy, reduce The effect of heavy labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

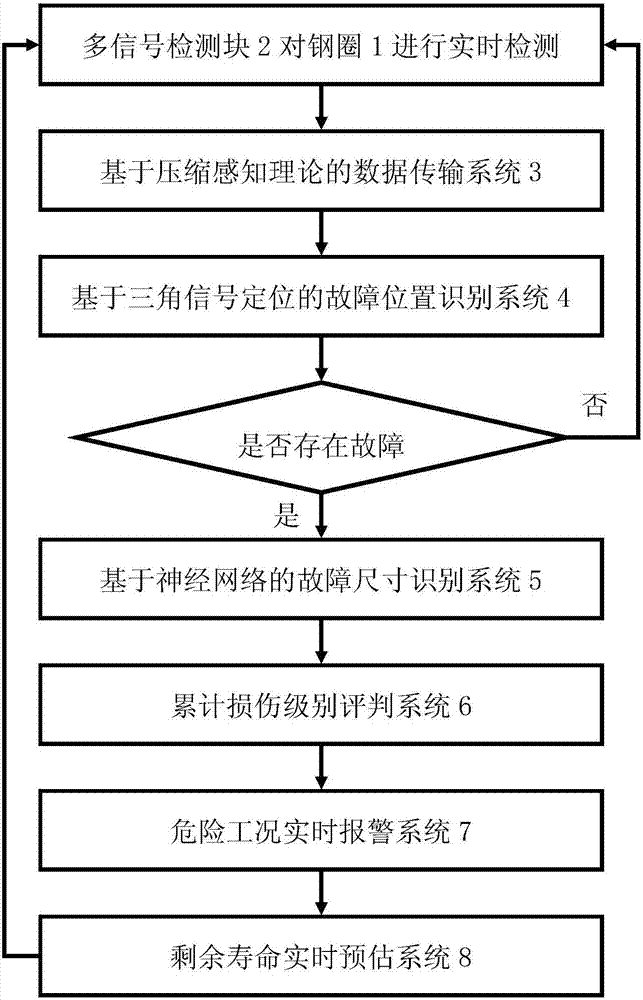

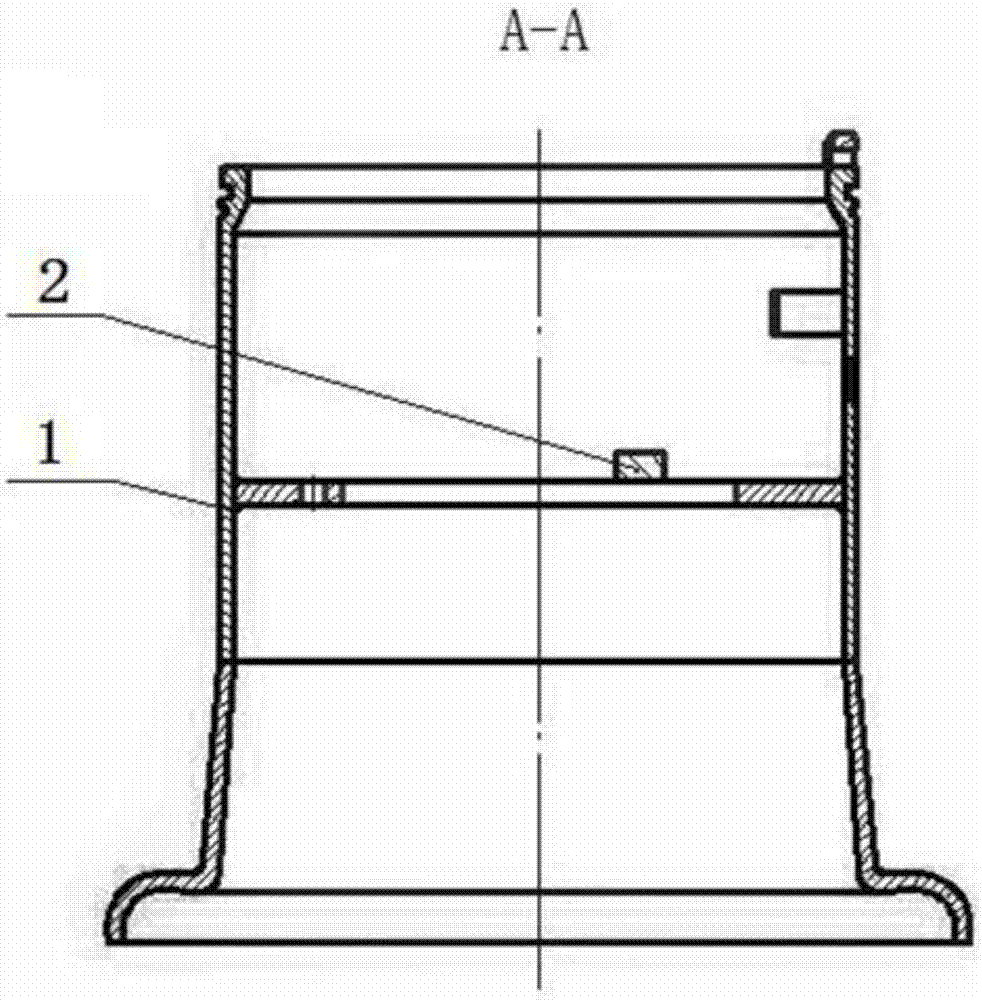

[0042] Such as Figure 1-Figure 5 As shown, a steel ring fault self-identification method includes the following steps:

[0043] a, signal detection system 2 is set on the steel ring main body 1, and described signal detection system 2 is a multi-signal detection block, which is distributed in a polygonal shape on the steel ring main body 1, and the multi-signal detection block is arranged on each vertex of the polygon, Real-time detection of steel ring body 1 by transmitting signals, and sending the detection information to data transmission system 3; at the same time, set up data transmission system 3, fault location identification system 4, and fault size identification system 5;

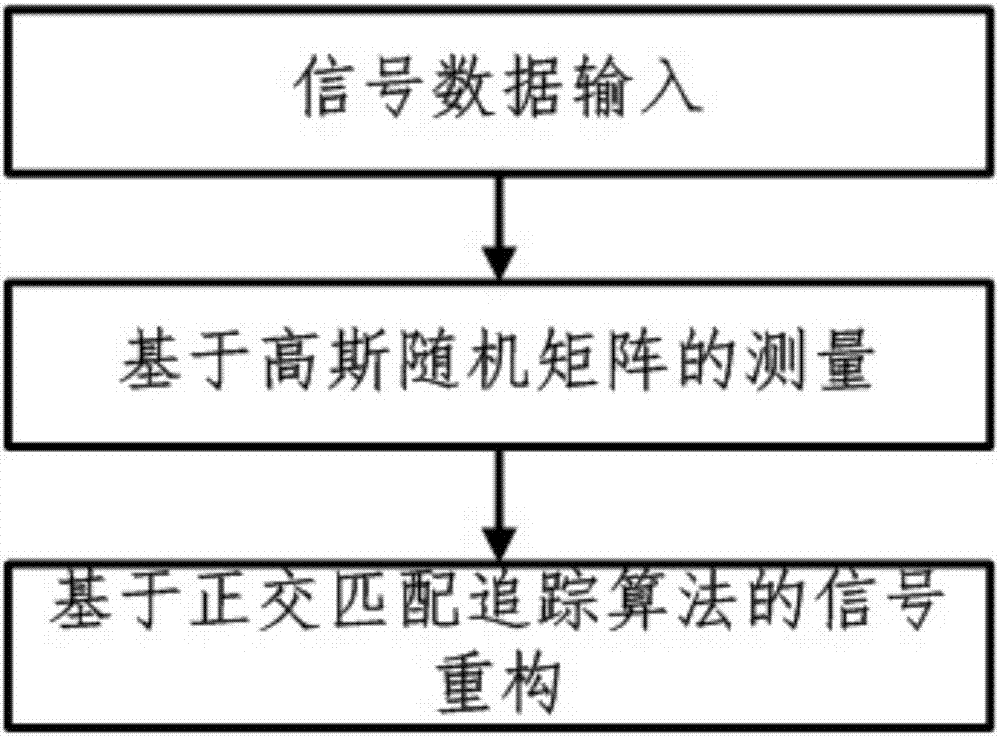

[0044] b. The signal detection system 2 receives the signal reflected by the steel ring body 1 and transmits it to the data transmission system 3, and the data transmission system 3 compresses the detection information and transmits it to the fault location identification system 4;

[0045]c. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com