A kind of porous glass microsphere SERS substrate embedded with silver nanoparticles and preparation method thereof

A technology of porous glass microspheres and silver nanoparticles, which can be applied to coatings and other directions, can solve the problems of unstable physical and chemical properties, easy to cause poisoning in the environment, complicated substrate preparation, etc., and achieves enhanced Raman signal, low equipment requirements, and preparation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

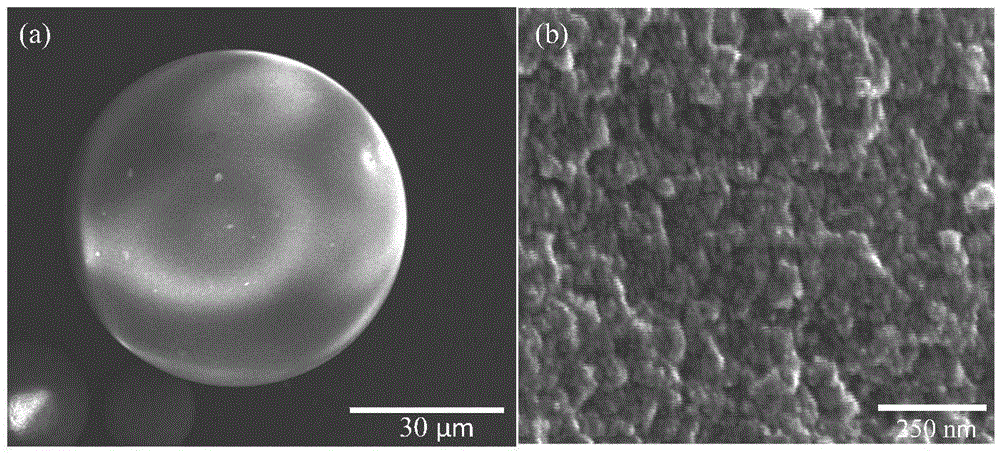

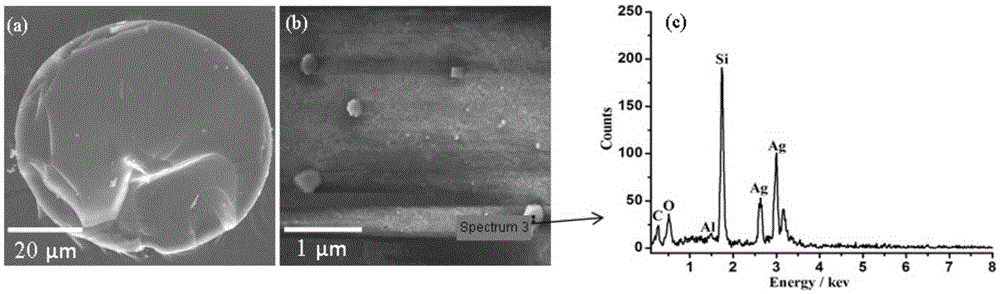

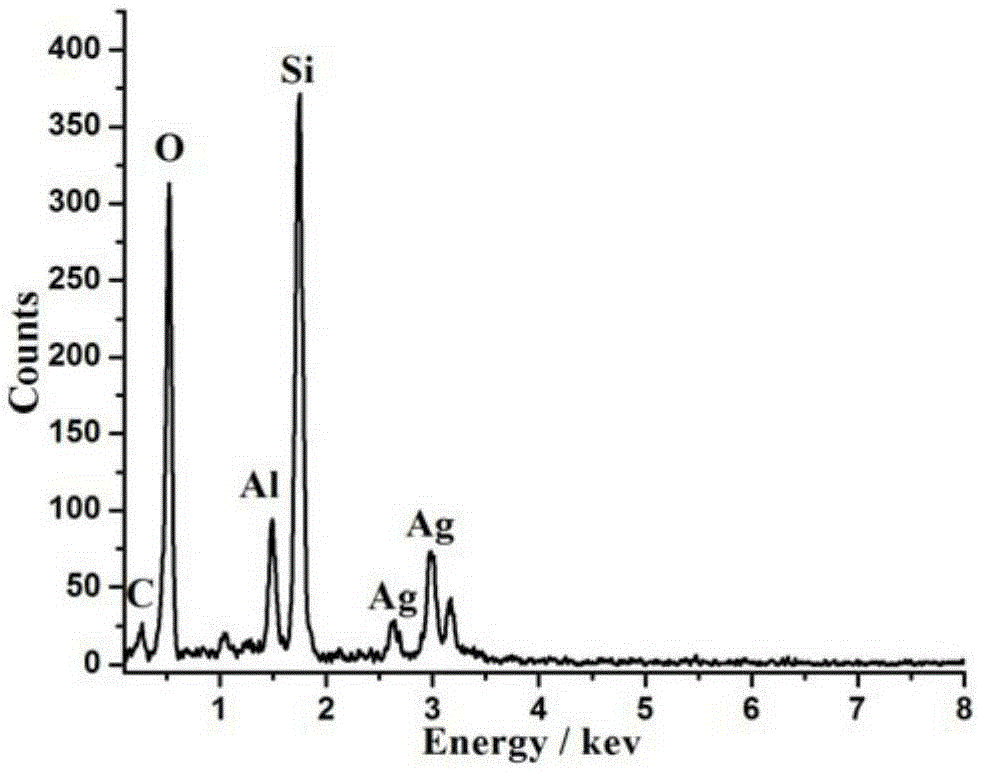

Image

Examples

Embodiment 1

[0031] A method for preparing a porous glass microsphere SERS substrate embedded with silver nanoparticles, the specific steps are as follows:

[0032] 1) Pipette 20ml of 0.1mol / L AgNO3 solution in a dark environment and place it in a small glass bottle with a sealed cap, put 0.05g of porous glass microspheres in the solution, and tighten the cap to seal;

[0033] Then place the small glass bottle in a large beaker containing 300ml of water and a magnetic rotor, and adjust the rotor speed to 300 rpm to make the microspheres-AgNO 3 The solution suspension is fully stirred (the suspension is placed in a small glass bottle, and the purpose of placing the rotor outside the glass bottle is to prevent the solution from being polluted);

[0034] After stirring for 16 hours, the small glass bottle was taken out, the suspension was transferred to a 40 cm long, clean, sealed stainless steel tube, and 150 psi of compressed CO was introduced into the tube. 2 gas, using high-pressure gas ...

Embodiment 2

[0042] A method for preparing a porous glass microsphere SERS substrate embedded with silver nanoparticles, the specific steps are as follows:

[0043] 1) Pipette 30ml of 0.05mol / L AgNO in a dark environment 3 The solution is placed in a small glass bottle with a sealed cap, 0.05 g of porous glass microspheres are placed in the solution, and the cap is tightly sealed;

[0044] Then place the small glass bottle in a large beaker containing 300ml of water and a magnetic rotor, and adjust the rotor speed to 500 rpm to make the microspheres-AgNO 3 After the solution suspension was fully stirred for 12 hours, the small glass bottle was taken out, the suspension was transferred to a 40 cm long, clean, sealed stainless steel tube, and 100 psi of compressed N 2 Gas, remove the compressed gas after 5 hours, take out the suspension and filter out the porous glass microspheres;

[0045] 2) After the porous glass microspheres treated in step 1) were rinsed with deionized water, put 0.2m...

Embodiment 3

[0048] A method for preparing a porous glass microsphere SERS substrate embedded with silver nanoparticles, the specific steps are as follows:

[0049] 1) Pipette 20ml of 0.05mol / L AgNO in a dark environment 3 The solution is placed in a small glass bottle with a sealed cap, 0.05 g of porous glass microspheres are placed in the solution, and the cap is tightly sealed;

[0050] Then place the small glass bottle in a large beaker containing 300ml of water and a magnetic rotor, and adjust the rotor speed to 800 rpm to make the microspheres-AgNO 3 After the solution suspension was fully stirred for 10 hours, the small glass bottle was taken out, the suspension was transferred to a 40 cm long, clean, sealed stainless steel tube, and 120 psi of compressed Ar gas was introduced into the tube, and the compressed gas was removed after 4 hours. Take out the suspension and filter out the porous glass microspheres;

[0051] 2) Rinse the porous glass microspheres treated in step 1) with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com