Fixing device

A technology of a rotating body and a rotating direction, which is applied to instruments, equipment of electrical recording technology applying charge patterns, optics, etc., can solve the problems of temperature drop of the fixing belt 506 and other problems, and achieve the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

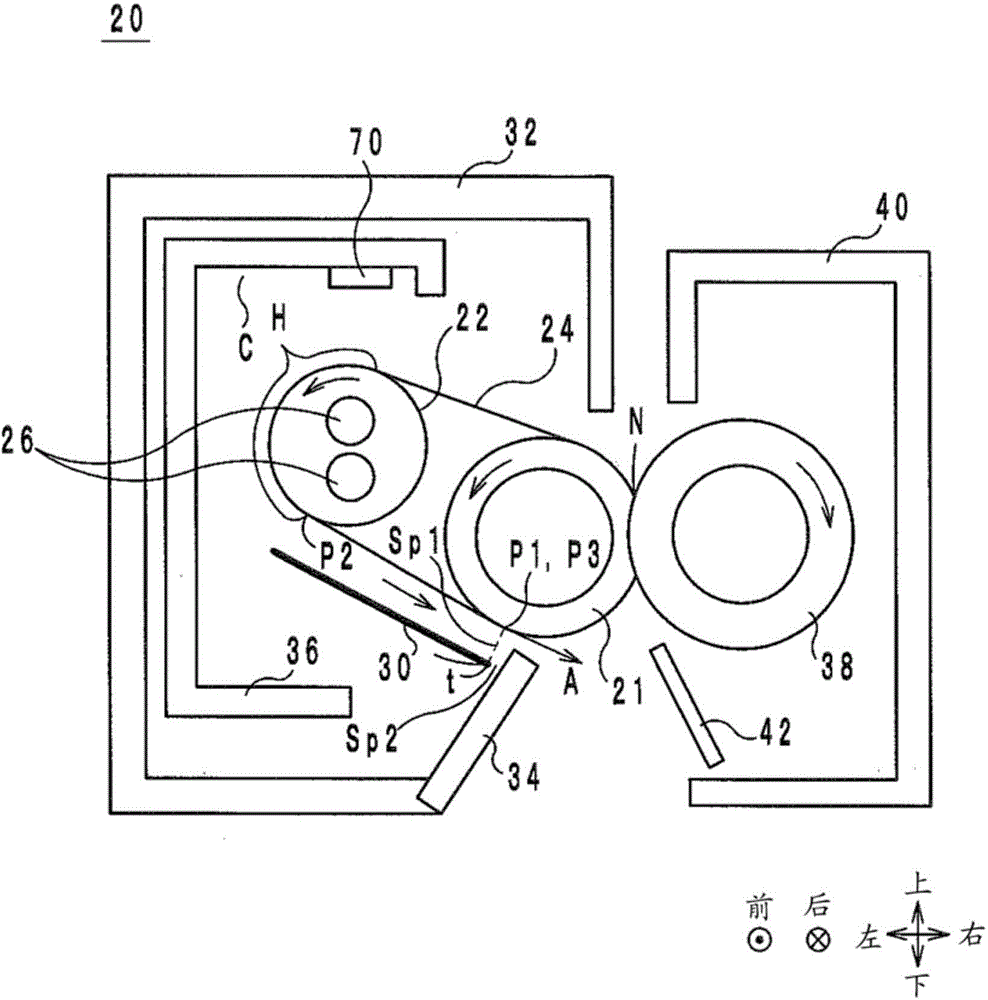

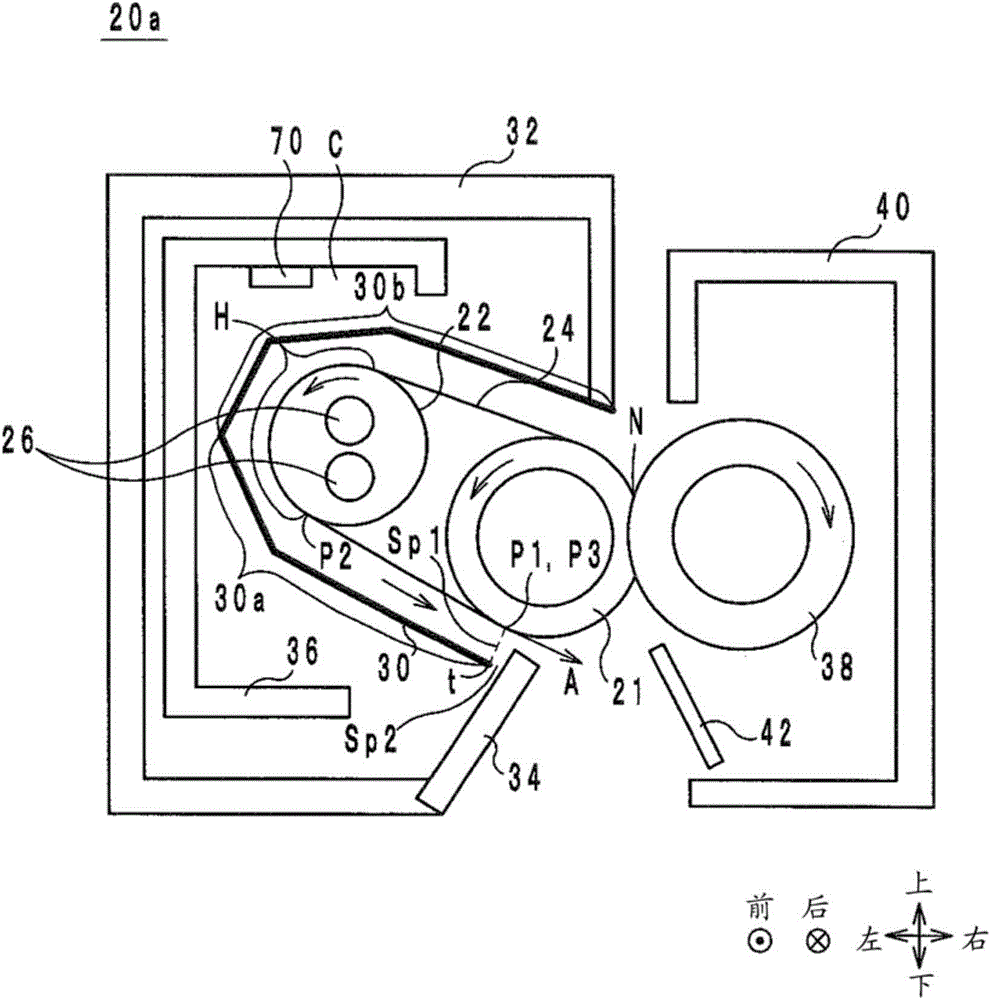

[0111] The fixing device of the present invention is not limited to the above-mentioned fixing devices 20 , 20 a , and 20 b , and changes can be made within the scope of the gist thereof.

[0112] Also, the reflection plate 30 and the rib 34 may be in contact, but preferably, their contact area is as small as possible. Thereby, heat conduction between the reflection plate 30 and the rib 34 can be suppressed.

[0113] In addition, the rib 34 may be integrated with the outer cover 32 . Thereby, a reduction in the number of parts is achieved.

[0114] In addition, the fixing roller 21 may be positioned obliquely above the heating roller 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com