Pile-net composite roadbed pile top differential settlement control method

A differential settlement and control method technology, applied to roads, roads, buildings, etc., can solve problems such as differential settlement of long-term pile networks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

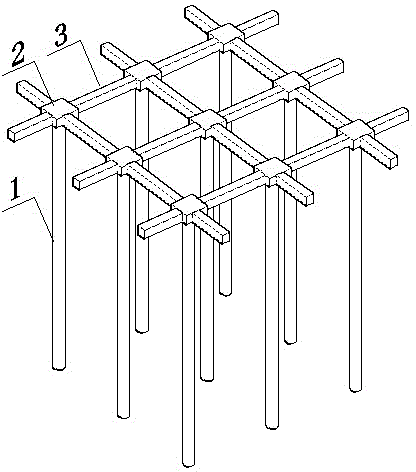

[0033] Such as figure 1 As shown, the pile-net composite subgrade pile top differential settlement control method of the present invention comprises the following steps:

[0034] Step 1: Analyze the road geological survey report, design the pile network and the upper cushion layer;

[0035] a) Analyze the geological survey report to draw a plane distribution map of the soft soil layer along the entire road, the thickness of the vertical soft soil layers, and indicate the physical and mechanical indicators of the classified soft soil, determine the pre-consolidation pressure of the silt according to the compression test, and compare the pre-consolidation Analyze the degree of silt consolidation and mark the under-consolidated area on the plan; check the geological exploration data along the line, and draw continuous curves of the thickness of the longitudinal and transverse layers on the left and right sides of the road.

[0036] b) Design the pile type, pile spacing and pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com