Circuit board plug-in component with roller groove

A technology for circuit board insertion and roller grooves, which is applied to circuits, electrical components, and parts of connecting devices, etc., can solve the problems of large connection insertion and extraction force, difficulty in manual insertion and extraction, and complicated circuit board structure, and achieves left-right movement. Smooth, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

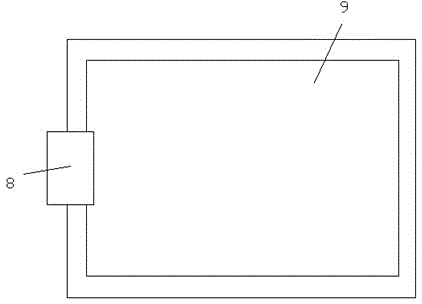

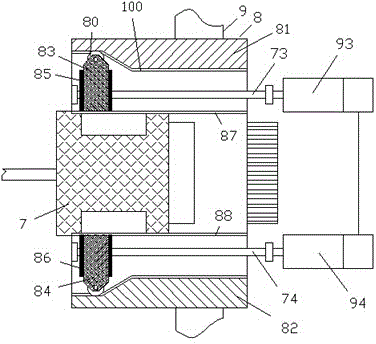

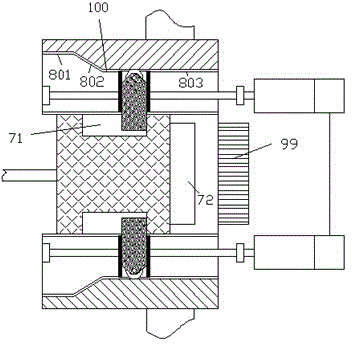

[0010] Through the implementation process of specific examples and combined Figure 1-3 Instead, the present invention will be described in detail.

[0011] A circuit board plug-in assembly with roller grooves according to the present invention includes a circuit board device 9 and an interface device 8 arranged on the left side of the circuit board device 9. The interface device 8 includes an upper profile part 81 and a lower profile part 82, the board body of the circuit board device 9 is provided with a pin array 99 at the part adjacent to the inner side of the housing to be inserted into the upper contour part 81 and the lower part of the interface device 8. The socket array 72 on the plug 7 between the profile parts 82 is engaged, and the upper profile part 81 and the lower profile part 82 are engaged with the rollers 80 on the upper slider assembly 83 and the lower slider assembly 84 respectively, and the upper slider assembly 83 and the lower slider assembly 84 are enga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com