Automobile clutch master cylinder

A clutch master cylinder, automobile technology, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of reducing driving comfort, difficulty in the return of the push rod, difficulty in the return of the pedal arm, etc., to eliminate discomfort, eliminate Negative pressure, the effect of reducing the return resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

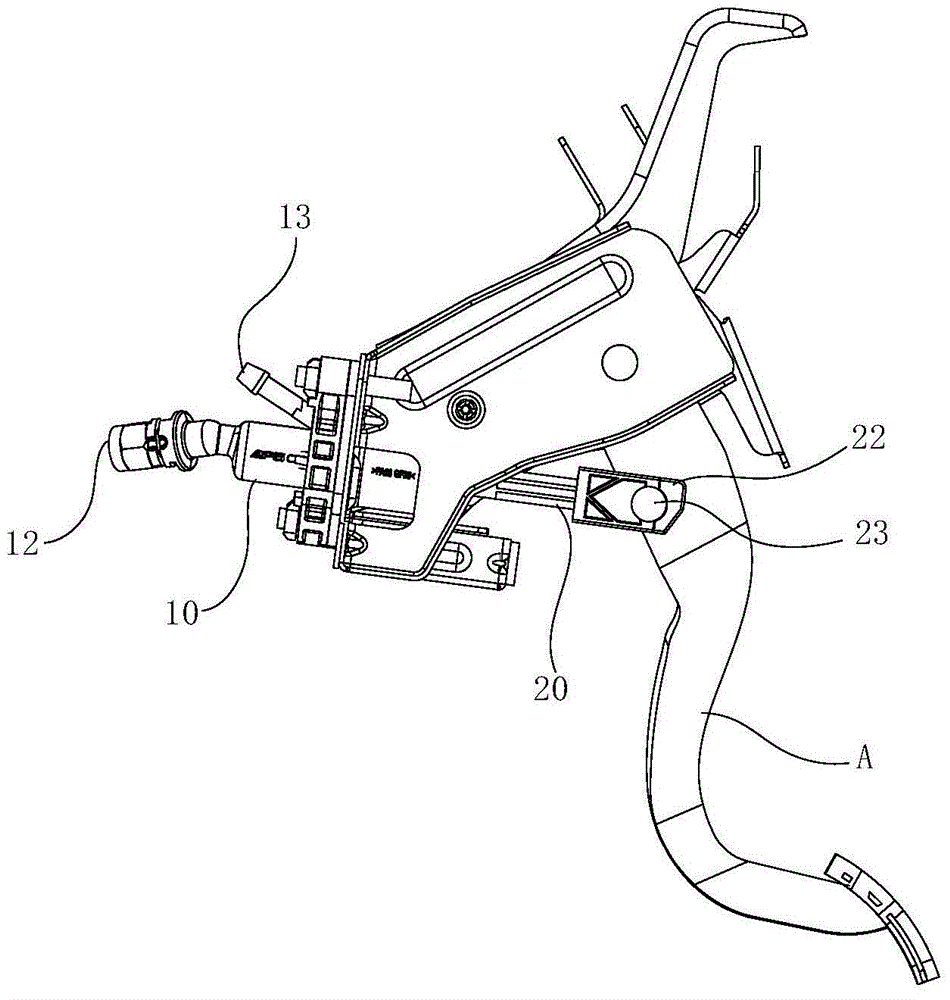

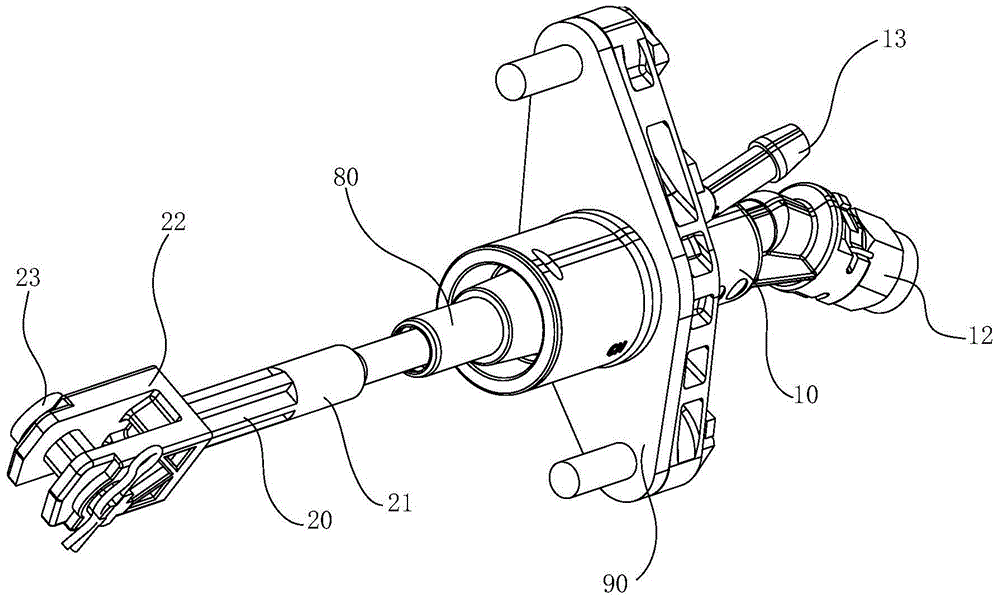

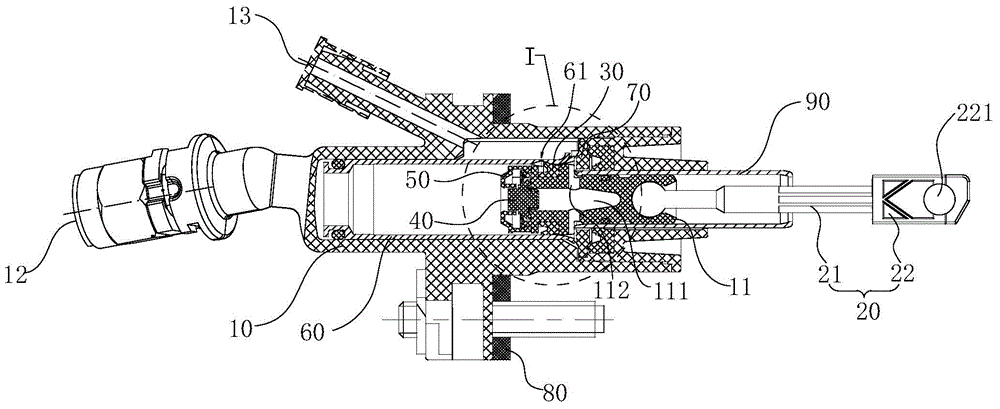

[0015] combined with Figures 1 to 11 , the present invention is described in further detail:

[0016] An automobile clutch master cylinder, comprising a cylinder body 10 and a piston 11 arranged in the cylinder body 10, a sealing ring 30 is arranged on the piston 11, and the sealing ring 30 divides the inner cavity of the cylinder body 10 into two chambers before and after, and the piston 11 The front end of the push rod 20 is connected to one end of the push rod 20, and the other end of the push rod 20 extends away from the cylinder block axially and is hingedly connected with the clutch pedal arm A. The rear end of the rear chamber of the cylinder block 10 is connected to the oil outlet pipe 12, The oil inlet pipe 13 is connected to the front chamber of the cylinder body 10 from the through hole provided on the pipe wall of the cylinder body 10, and the piston 11 is provided with a passage 111 connecting the front and rear chambers of the cylinder body 10, and a check valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com