An electrolytic aluminum tank shelling device

A technology of shelling device and electrolytic aluminum tank, which is applied in the field of electrolytic aluminum auxiliary equipment, can solve the problems of slow start-up speed, large distance between fixed points, loss of shelling hammer, etc., so as to improve start-up speed and return speed, and avoid soaking damage , The effect of reducing the return resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

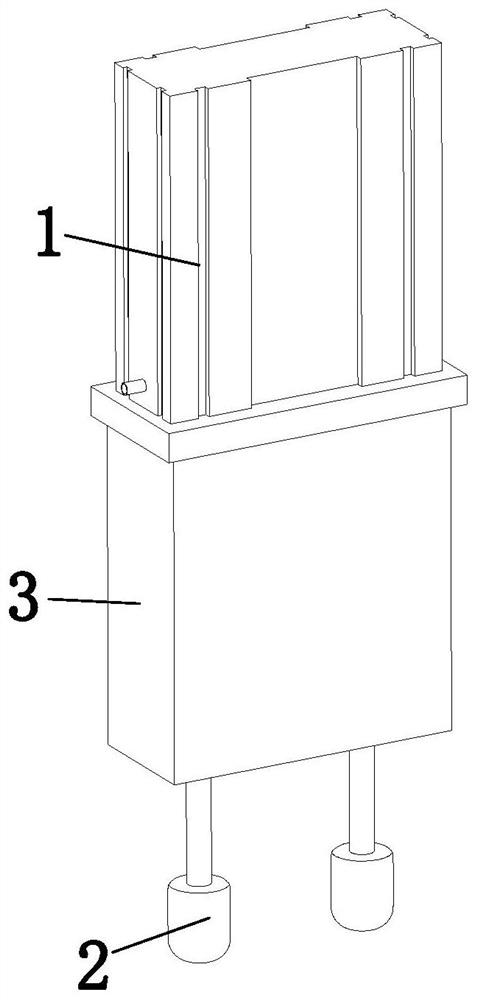

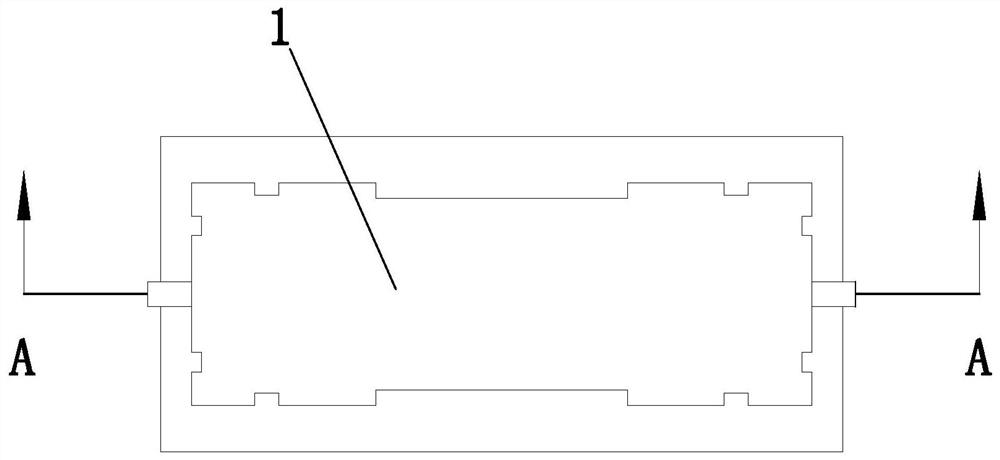

[0032] refer to Figure 1 to Figure 6It can be seen that a shelling device for an electrolytic aluminum tank includes a shelling cylinder 1 and two shelling assemblies 2, the two shelling assemblies 2 are arranged symmetrically and both shelling assemblies 2 are fixedly connected to the shelling cylinder 1 , the lower end of the shelling cylinder 1 is provided with a guide assembly 3 fixedly connected thereto, the guide assembly 3 is sleeved on the outside of the two shelling assemblies 2, and the inside of the guide assembly 3 is provided with a magnetic auxiliary assembly 4, The two shell-beating assemblies 2 all cooperate with the magnetic auxiliary assembly 4, and the upper part of the guide assembly 3 is provided with a connecting assembly 6, and the two shell-beating assemblies 2 are connected through the connecting assembly 6; when the present invention is in use, The shelling cylinder 1 works to drive the two shelling assemblies 2 to work alternately for shelling. Duri...

Embodiment 2

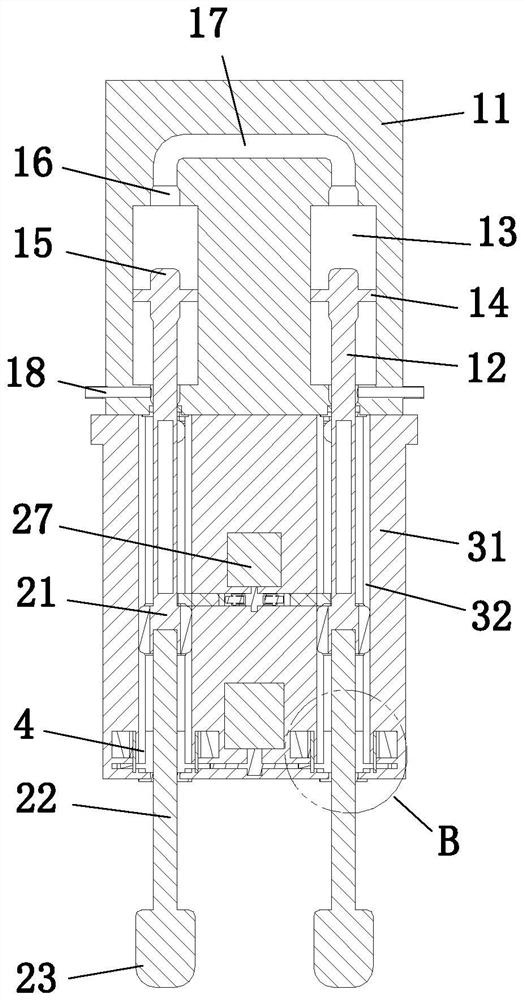

[0042] Embodiment two; With reference to Figure 7 to Figure 9 It can be seen that the shelling cylinder 1 includes a shell 11 and two output shafts 12, the inside of the shell 11 is provided with two air pressure grooves 13, one end of the two output shafts 12 is provided with a piston 14, and the two output shafts 12 are provided with a piston 14. Piston 14 is respectively located in two air pressure grooves 13 and each piston 14 is all slidably matched with air pressure groove 13, and the upper and lower ends of each described piston 14 are all provided with buffer blocks 15, and the upper and lower ends of described air pressure groove 13 are both Be provided with the buffer groove 16 that communicates with it and cooperate with buffer block 15, the side of each described buffer groove 16 is all provided with the air pipe 19 that communicates with it, the side of described shelling cylinder 1 is provided with two The air pressure pipe 110, the air pipe 19 above each air pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com