Preparation Method of Gel Casting Molding of Metal/Ceramic Gradient Material in Alternating Magnetic Field

A technology of alternating magnetic field and gradient material, applied in the field of material preparation, to achieve the effects of wide application range, cost reduction and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

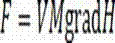

Method used

Image

Examples

Embodiment 1

[0047] 1) Preparation of mold

[0048] A plexiglass mold is used, and the inner cavity of the mold is a disc with a height of 15mm and a diameter of 15mm;

[0049] 2) Slurry preparation

[0050] Metallic Cu particles with a particle size of 0.1 μm and ZrO particles with a particle size of 0.1 μm 2 The ceramic particles are mixed into a mixed powder according to the mass ratio of 0.1:1; the organic monomer acrylamide and the crosslinking agent methylenebisacrylamide are dissolved in deionized water at a weight ratio of 6:1, and the mass fraction of organic matter is 10%. The premix solution; the mixed powder is added to the premix solution, and the dispersant ammonium polyacrylate is added at the same time. The content of the dispersant agent is 0.05% of the mass of the slurry. Ball milling in a ball mill for 1 hour, ultrasonic dispersion treatment for 1 minute, to obtain a dispersed slurry, slurry The volume content of solid phase in medium is 50%;

[0051] Step 3) Injectio...

Embodiment 2

[0057] 1) Preparation of mold

[0058] A plaster mold is used, and the inner cavity of the mold is a disc with a height of 15mm and a diameter of 15mm;

[0059] 2) Slurry preparation

[0060] Mix metal Al particles with a particle size of 1 μm and SiC ceramic particles with a particle size of 0.1 to 1000 μm at a mass ratio of 1:1 to form a mixed powder; Dissolve it in deionized water at a weight ratio of 8:1 to prepare a premixed solution with an organic mass fraction of 15%; add the mixed powder to the premixed solution, and add the dispersant SD-38 at the same time, and the content of the dispersant is 0.1% of the mass of the slurry , ball milling in a ball mill for 2h, ultrasonic dispersion treatment for 3min, to obtain a dispersed slurry, the solid phase volume content in the slurry is 60%;

[0061] Step 3) Injection molding in alternating magnetic field

[0062] Add the initiator ammonium persulfate solution occupying 1% of the organic monomer amount and the catalyst t...

Embodiment 3

[0067] 1) Preparation of mold

[0068] The wooden mold is used, and the inner cavity of the mold is a disc with a height of 15mm and a diameter of 15mm;

[0069] 2) Slurry preparation

[0070] Metallic Ag particles with a particle size of 10 μm and SiO with a particle size of 10 μm 2 The ceramic particles are mixed into a mixed powder at a mass ratio of 0.1:1; the organic monomer vinylpyrrolidone and the crosslinking agent methylene bisacrylamide are dissolved in deionized water at a weight ratio of 12:1, and the mass fraction of the organic matter is 20% premix solution; add the mixed powder into the premix solution, and add dispersant JA-281 at the same time, the dispersant content is 0.20% of the mass of the slurry, ball mill in a ball mill for 5 hours, and ultrasonically disperse for 5 minutes to obtain a dispersed slurry. The solid phase volume content in the slurry is 70%;

[0071] Step 3) Injection molding in alternating magnetic field

[0072] Add the initiator amm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com