Preparation Method of Metal/Ceramic Gradient Material by Pressure Filtration in Alternating Magnetic Field

A technology of alternating magnetic field and press-filter molding, which is applied in the field of material preparation to achieve the effects of cost reduction, process simplification and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

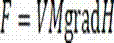

Method used

Image

Examples

Embodiment 1

[0028] 1) Mold preparation

[0029] Mix α-gypsum and β-gypsum mixed gypsum powder with water, add polyvinyl fluoride organic additives, the content of which is 5% of the mass of gypsum, stir for 3 minutes and pour, and the gypsum slurry is solidified, hardened and dried to make Obtain a gypsum mold, the inner mold cavity of the mold is a disc with a height of 15mm and a diameter of 15mm;

[0030] 2) Slurry preparation

[0031] Metallic Cu particles with a particle size of 0.1 μm and ZrO particles with a particle size of 0.1–1000 μm 2 Mix the ceramic particles according to the mass ratio of 0.1:1, add deionized water until the solid phase content reaches 30vol%, ball mill in a ball mill for 1 hour, and ultrasonically disperse for 1 minute to prepare a dispersed slurry;

[0032] 3) Press filter forming in alternating magnetic field

[0033] The dispersion slurry is injected into the plaster mold, and an alternating magnetic field is applied outside the mold. The alternating m...

Embodiment 2

[0038] 1) Mold preparation

[0039] Mix α-gypsum and β-gypsum mixed gypsum powder with water, add melamine resin organic additive, the content of which is 10% of the mass of gypsum, stir for 5 minutes and pour, and the gypsum slurry is solidified, hardened and dried to obtain gypsum Mold, the inner cavity of the mold is a disc with a height of 15mm and a diameter of 15mm;

[0040] 2) Slurry preparation

[0041] Mix metal Al particles with a particle size of 1 μm and ceramic SiC particles with a particle size of 1 μm at a mass ratio of 1:1, add deionized water until the solid phase content reaches 40vol%, ball mill in a ball mill for 2 hours, and ultrasonically disperse for 3 minutes , making a dispersion slurry;

[0042] 3) Press filter forming in alternating magnetic field

[0043] The dispersion slurry is injected into the plaster mold, and an alternating magnetic field is applied outside the mold. The alternating magnetic field is generated by the alternating current passi...

Embodiment 3

[0048] 1) Mold preparation

[0049] Mix α-gypsum and β-gypsum mixed gypsum powder with water, add phenolic resin organic additives, the content of which is 15% of the mass of gypsum, stir for 8 minutes and pour, and the gypsum slurry is solidified, hardened and dried to obtain gypsum Mold, the inner cavity of the mold is a disc with a height of 15mm and a diameter of 15mm;

[0050] 2) Slurry preparation

[0051] Metallic Ag particles with a particle size of 10 μm and ceramic SiO with a particle size of 10 μm 2 Mix the particles according to the mass ratio of 0.1:1, add deionized water until the solid phase content reaches 45vol%, ball mill in a ball mill for 5 hours, and ultrasonically disperse for 8 minutes to prepare a dispersed slurry;

[0052] 3) Press filter forming in alternating magnetic field

[0053] The dispersion slurry is injected into the plaster mold, and an alternating magnetic field is applied outside the mold. The alternating magnetic field is generated by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com