Large-diameter support roller integral induction heating system and control method thereof

A technology of induction heating and control methods, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve the problems of large volume, difficult temperature gradient distribution, affecting the use effect and life of rolls, etc., to ensure the effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

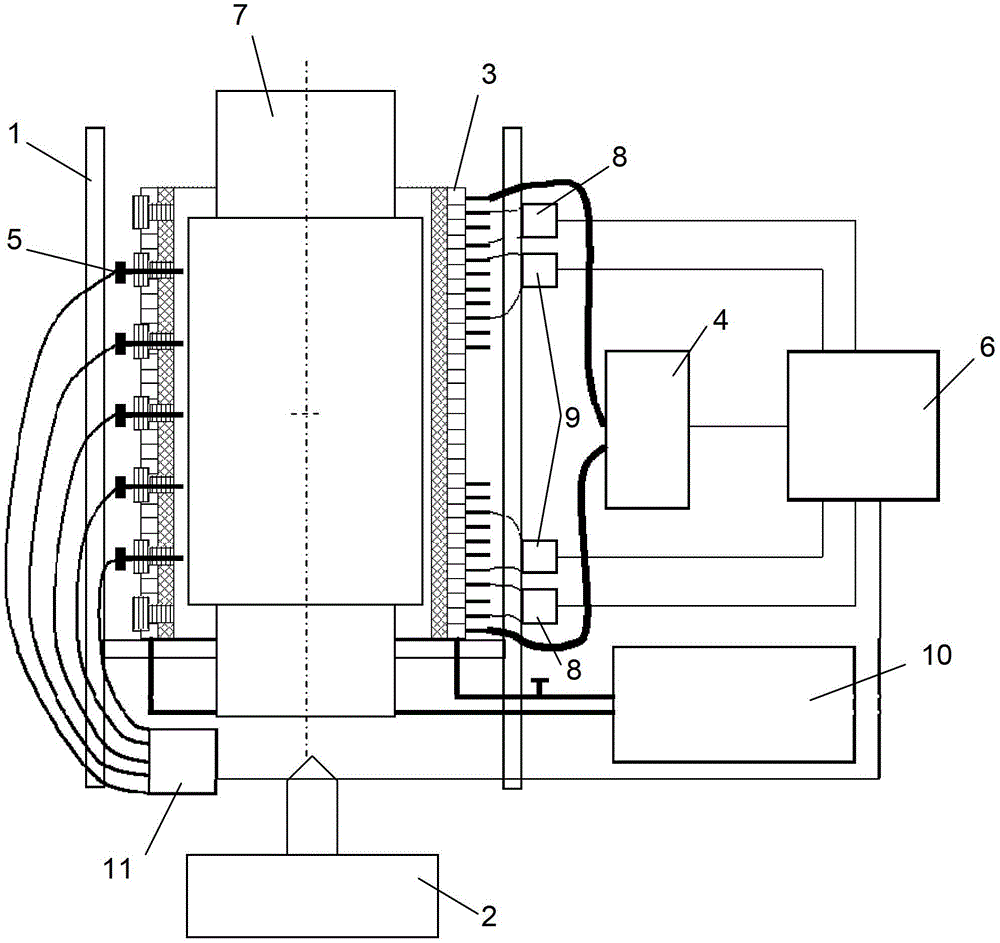

[0037] see figure 1 As shown, the overall induction heating system for large-diameter backup rolls of the present invention specifically includes a heating platform 1, a mechanical transmission mechanism 2, a coil 3, a power supply 4, several temperature measuring probes 5, an end compensation unit, and a closed-loop control unit 6, wherein, The heating platform 1 is used to ensure that the center position of the coil 3 and the center position of the workpiece 7 basically coincide with each other. The axis of the coil 3 is vertical to the ground, and for the convenience of heating workpieces 7 of different specifications, the heating platform 1 can move in the vertical direction. The mechanical transmission mechanism 2 is set under the heating platform 1 to carry the workpiece 7 to be heated and quenched, and during the whole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com