Efficient steam generator

A steam generator and high-efficiency technology, applied in the field of high-efficiency steam generators with high conversion efficiency, can solve problems such as short range of steam, low heating efficiency, steam flow rate, uneven temperature, etc., and achieve high steam pressure and heat conversion efficiency Elevation, the effect of high steaming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

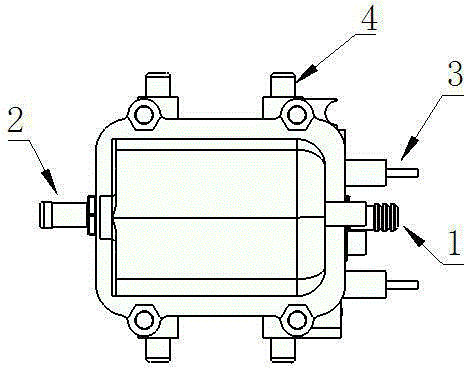

[0015] The high-efficiency steam generator structure designed by the present invention includes: the generator cavity itself ( figure 1 ), the heating tube (3), the upper casing, the lower casing, the water inlet (1), the steam outlet (2), and the temperature control switch (5) formed by integral casting with the heating body.

[0016] The heating pipe (3) is in a spiral structure.

[0017] figure 1 This is the appearance of the high-efficiency steam generator, which is composed of upper and lower shells and a central cavity, and positioning columns (4) are designed around the generator.

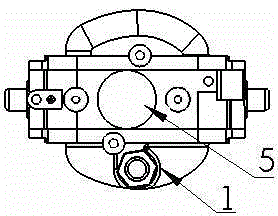

[0018] figure 2 Its side view, (5) is the installation position of the temperature control switch.

[0019] The steam vent is equipped with a small nozzle (2) with a special diameter.

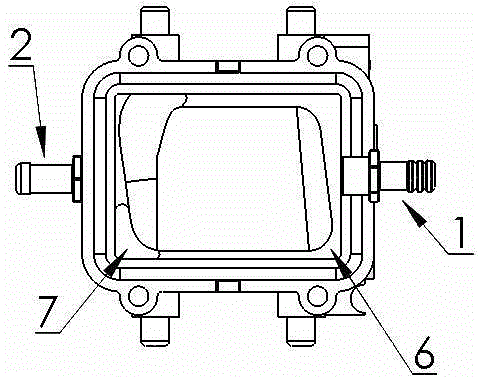

[0020] The generator chamber itself (as image 3 , Figure 4 ) The internal steam outlet channel is specially designed to make the water vapor flow in a roundabout way, make full use of the heating tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com