An ultra-low tension doffing device

A low-tension, cloth-falling technology, applied in transportation and packaging, folding thin materials, thin material processing, etc., can solve the problems that affect the appearance and quality of cloth, and the indentation is difficult to eliminate, so as to solve the problem of cloth edge indentation and cloth falling No indentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

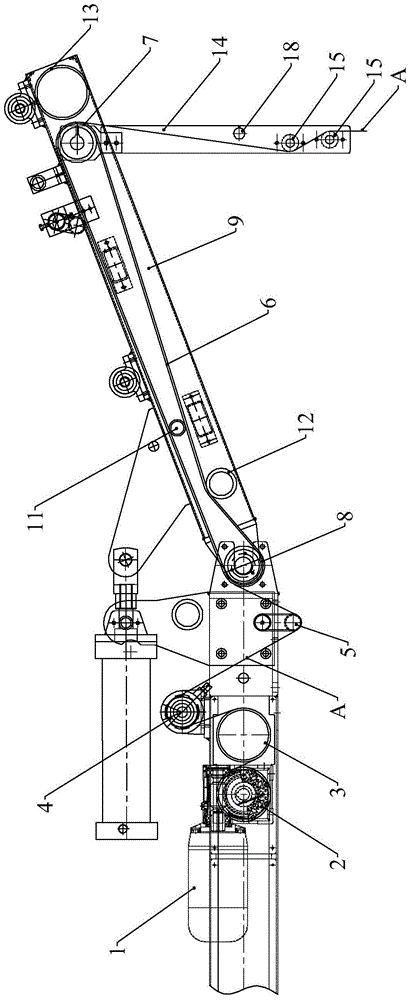

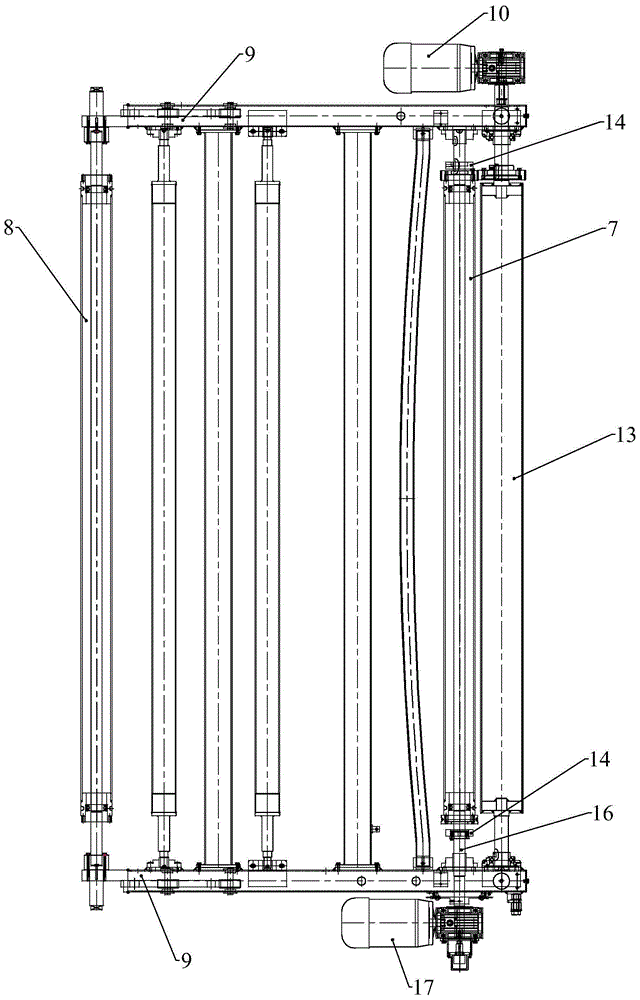

[0012] refer to Figure 1 to Figure 2 , the present embodiment includes a low-tension cloth feeding mechanism, a transmission mechanism and a swing mechanism; the low-tension cloth feeding mechanism includes a driving motor 1, a first driving roller 2, a second driving roller 3, a tension sensor 4 and a bending roller 5, and the driving motor drives The first driving roller makes the cloth A enter the transmission mechanism through the first driving roller, the second driving roller, the tension sensor and the bending roller in sequence; the transmission mechanism includes a transmission belt 6, a driving roller 7 and a driven roller 8, and the driving roller and the driven roller Erected on the installation beam 9, the driving roller is driven by the transmission belt motor 10 through gear meshing, the inner side of the transmission belt is supported by the support roller 11, and the outer side of the transmission belt is tensioned by the tension roller 12; the swing mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com