A kind of anti-indentation amino baking varnish and preparation method thereof

An amino baking varnish and anti-indentation technology, which is applied in coatings, polyester coatings, etc., can solve problems such as inability to assemble vehicles, indentations on the contact surface of the wheel hub, and affect the appearance, and achieve the effect of improving the product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

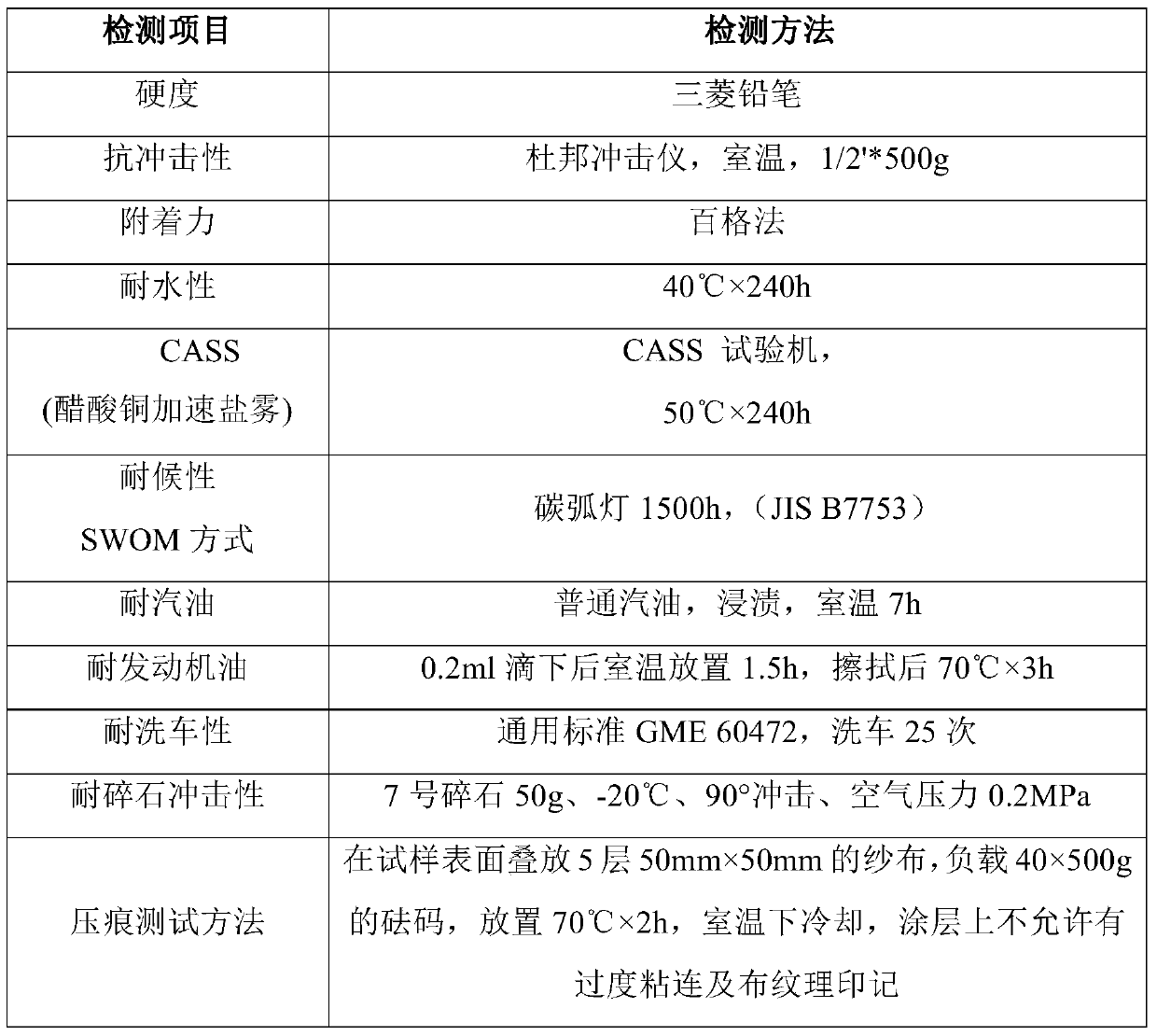

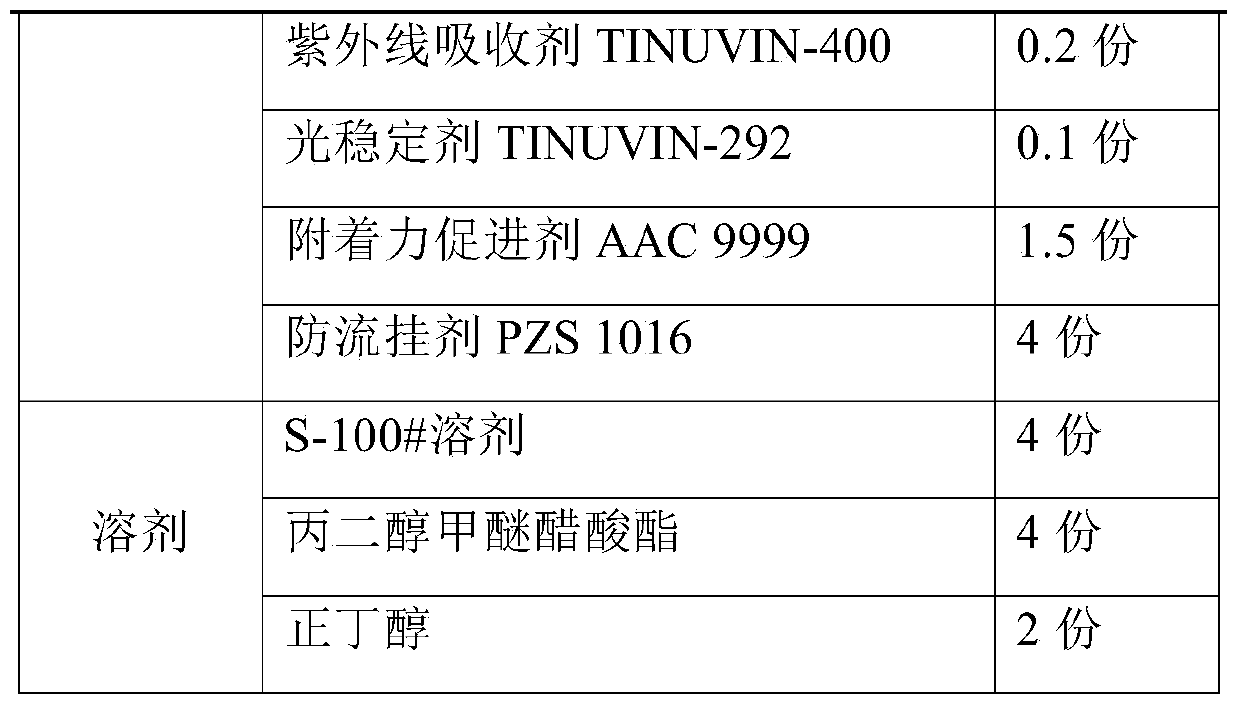

[0045] Table 2: Example 1 components and their content (parts by weight)

[0046]

[0047]

[0048] Step 1: Add 4 parts of solvent S-100# solvent into the stirring tank, slowly add 4 parts of anti-sagging agent PZS 1016 and 18.5 parts of amino resin US-138BB-70 in a stirring state, and stir at 150r / min 8min;

[0049] Step 2: Slowly add 4 parts of propylene glycol methyl ether acetate, 2 parts of n-butanol, 42.3 parts of polyester modified thermosetting acrylic resin SWK 337, 2 parts of blocked isocyanate resin BL 3175, and 0.2 parts of leveling Agent BYK-315, 0.2 parts of ultraviolet absorber TINUVIN-400, 0.1 part of light stabilizer TINUVIN-292 and 1.5 parts of adhesion promoter AA9999, after feeding, increase the stirring speed to 350r / min and continue stirring for 30min before filtering, The discharge obtains the described anti-indentation amino baking varnish applied to the varnish coating of automobile hubs.

[0050] Dilute the viscosity of the anti-indentation am...

Embodiment 2

[0062] Components and content of embodiment 2 are shown in Table 5,

[0063] Table 5: Embodiment 2 components and their contents (parts by weight)

[0064]

[0065] Step 1: Add 6 parts of solvent S-100# solvent into the stirring tank, slowly add 4.8 parts of anti-sagging agent PZS 1016 and 18.5 parts of amino resin US-138BB-70 at a stirring speed of 250r / min, and stir 15min;

[0066] Step 2: Slowly add 9 parts of propylene glycol methyl ether acetate, 5 parts of n-butanol, 55 parts of polyester modified thermosetting acrylic resin HR 7054, 3 parts of blocked isocyanate resin, and 0.3 parts of leveling agent BYK -315, 0.3 parts of UV absorber TINUVIN-400, 0.2 parts of light stabilizer TINUVIN-292 and 1.9 parts of adhesion promoter AA 9999, after feeding, increase the stirring rate to 550r / min and continue stirring for 40min before filtering and discharging The described anti-indentation amino baking varnish that is applied to the varnish coating of automobile hubs is obtai...

Embodiment 3

[0068] The components and content of embodiment 3 are shown in Table 6,

[0069] Table 6: Embodiment 3 components and their contents (parts by weight)

[0070]

[0071] Step 1: Add 5 parts of solvent S-100# into the stirring tank, slowly add 4.8 parts of anti-sagging agent PZS 1016 and 21.6 parts of amino resin BR 20SE at a stirring speed of 200r / min, and stir for 10 minutes;

[0072] Step 2: Slowly add 9 parts of propylene glycol methyl ether acetate, 2 parts of n-butanol, 42.3 parts of polyester modified thermosetting acrylic resin SWK 337, 2.2 parts of blocked isocyanate resin, and 0.3 parts of leveling agent BYK -315, 0.25 parts of UV absorber TINUVIN-400, 0.15 parts of light stabilizer TINUVIN-292 and 1.9 parts of adhesion promoter AA9999. After feeding, increase the stirring speed to 450r / min and continue stirring for 35 minutes before filtering and discharging The described anti-indentation amino baking varnish applied to the finish coating of automobile hubs is obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com