Guide roller for preventing wide copper foil from being tightened and electrolytic copper foil splitting machine

A technology of electrolytic copper foil and guide roller, which is applied in metal processing, winding strips, and sending objects, etc. It can solve the problems of foil surface knock marks, difficult to grasp the force, and no large-scale and wide foil wrinkling reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Discovery of the problem

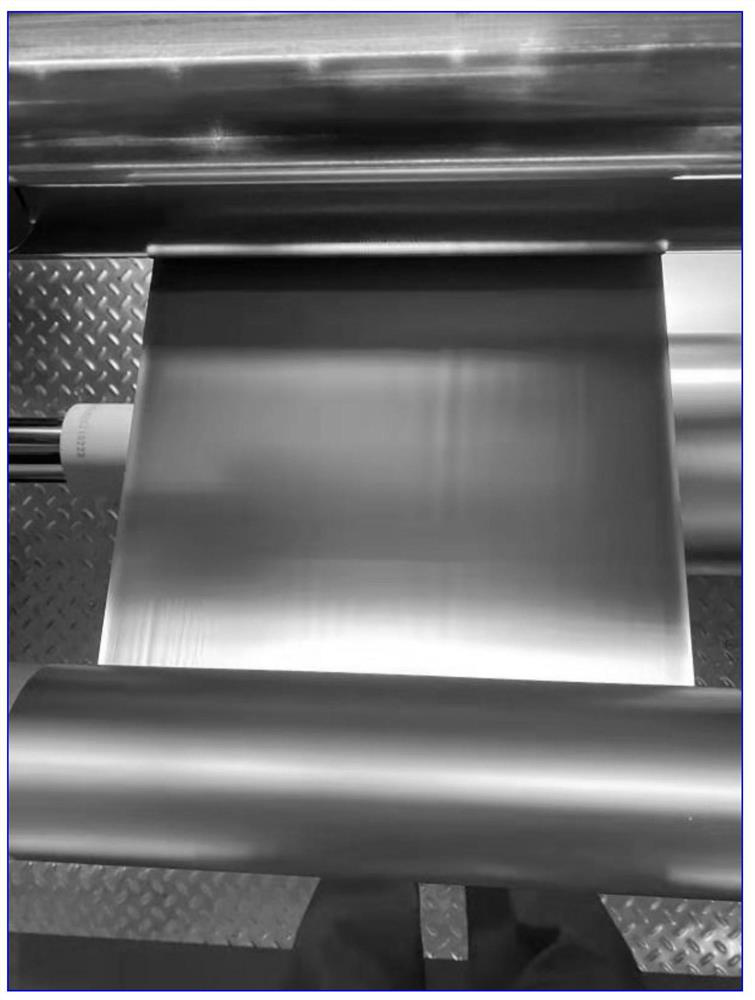

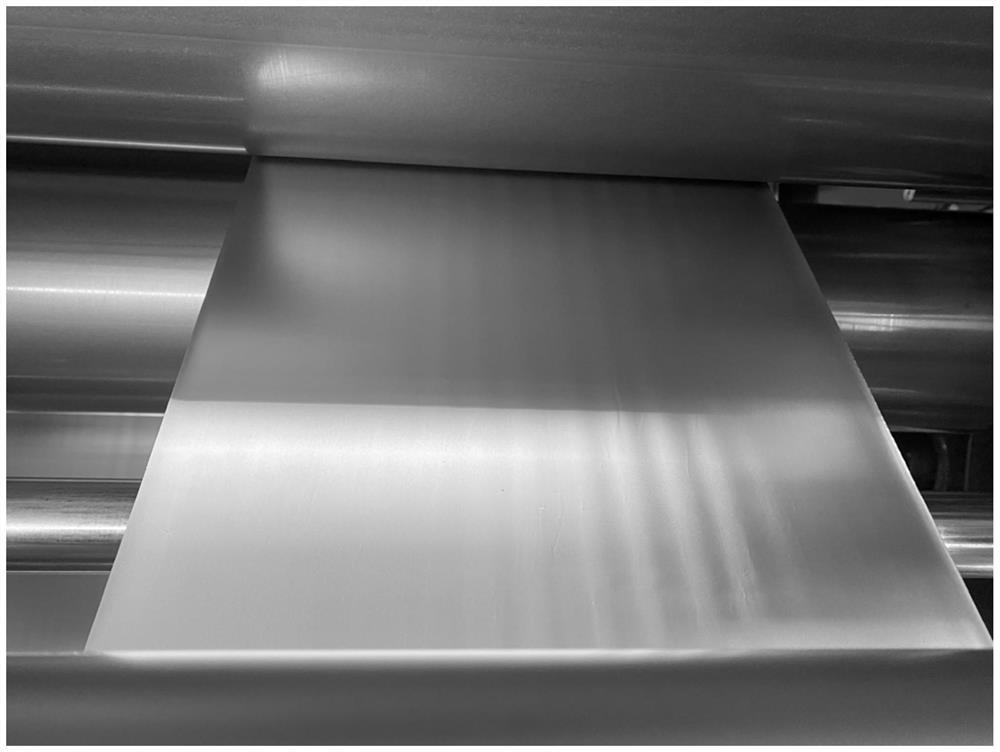

[0036] As mentioned in the background technology: when the copper foil is slitting, the copper foil will be tightened towards the middle for a large width of the foil during slitting, and the copper foil roll will wrinkle.

[0037] After a lot of data analysis: when the copper foil obtained by slitting is more than 800mm, it is very easy to wrinkle. For example: 1400mm original foil, cut into three parts: 300mm+800mm+300mm, 800mm copper foil will wrinkle, while 300mm has a lower probability of wrinkle.

[0038] In other words, the smaller the width of the slit copper foil, the lower the possibility of wrinkling.

[0039] 2. Reason Analysis

[0040] What is the reason for the wrinkling of the above-mentioned copper foil surface:

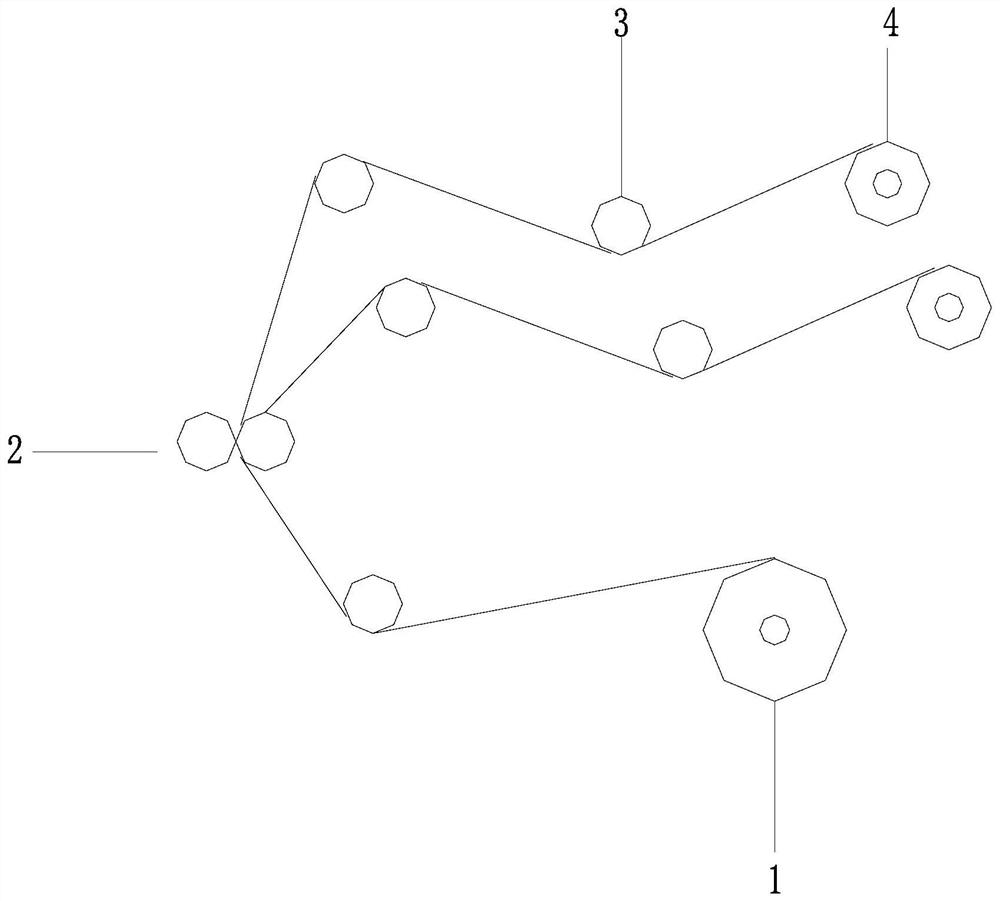

[0041] 1) For the slitting machine, the copper foil needs to pass through 7-9 shafts from unwinding to winding, that is, the number of passing shafts is relatively large;

[0042] 2) The spacing between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com