Single-column double-point inward-opening invisible safety gate link mechanism

A technology of connecting rod mechanism and safety door, which is applied in the direction of building structure, building, building fastening device, etc., can solve the problems of weak lock mechanism of the cabin, threat to the life of the crew, breaking into the door, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

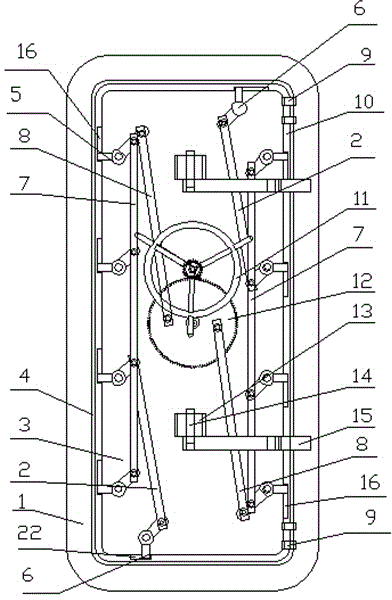

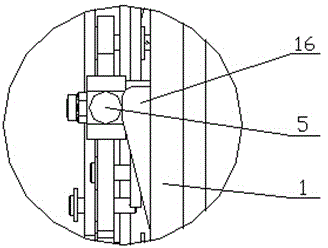

[0025] A single-column double-point inner-opening hidden safety door link mechanism is characterized in that the link mechanism is divided into left and right link mechanisms, and the left and right link mechanisms have the same structure. The left and right link mechanisms at least include a first link 8 and a second link 7, one end of the first link 8 is connected to the large gear plate shaft, and the other end of the first link 8 is connected to the second link 7 through the connecting plate. connection, the second connecting rod 7 is parallel to the left and right sides of the door frame 1, and the second connecting rod 7 is distributed with a plurality of door buckle mechanisms from top to bottom; the door frame 1 is connected with the door panel 3 through the door ear 9 and the door shaft 10; the door panel 3 is connected with operating handwheel 11 on the central axis.

Embodiment 2

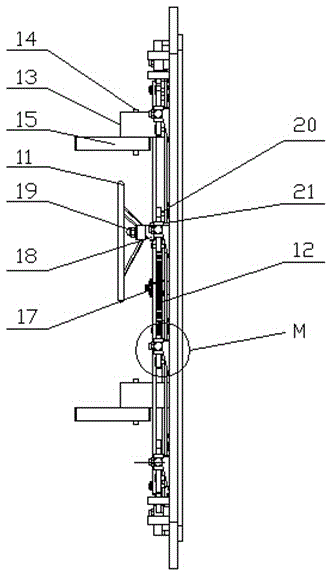

[0027] A single-column double-point inward-opening invisible safety door adopting the linkage mechanism at least includes a door frame 1 and a door panel 3, and the door frame 1 is connected to the door panel 3 through the door lug 9 and the door shaft 10, and is characterized in that: the central axis of the door panel 3 An operating handwheel 11 is connected to the top, and there is a pinion 20 on the shaft of the operating handwheel 11. The pinion 20 is coupled with the teeth of the large gear 12 at the lower end of the central axis. The left and right gear plates of the large gear 12 are respectively connected with a set of linkage mechanisms and door buckles. Mechanism is connected door buckle mechanism by left and right link mechanisms, and the left and right frames of door frame 1 are compressed or clutched by the compression wedge of door buckle mechanism.

[0028] The left and right link mechanisms have the same structure.

[0029] The left and right link mechanisms a...

Embodiment 3

[0038]A single-column double-point inward-opening invisible safety door adopting the linkage mechanism at least includes a door frame 1 and a door panel 3, and the door frame 1 is connected to the door panel 3 through the door lug 9 and the door shaft 10, and is characterized in that: the central axis of the door panel 3 An operating handwheel 11 is connected to the top, and there is a pinion 20 on the shaft of the operating handwheel 11. The pinion 20 is coupled with the teeth of the large gear 12 at the lower end of the central axis. The left and right gear plates of the large gear 12 are respectively connected with a set of linkage mechanisms and door buckles. Mechanism is connected door buckle mechanism by left and right link mechanisms, and the left and right frames of door frame 1 are compressed or clutched by the compression wedge of door buckle mechanism.

[0039] On the central axis of the door panel 3, there are respectively a door turn mounting seat 13 and a door tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com