Water pump selection method for low-lift pump unit based on impeller nominal average flow speed

A technology of average flow rate, low lift pump, applied to the components of pumping device for elastic fluid, pump device, axial flow pump, etc. Energy performance and cavitation performance, the effect of reducing the head loss of the flow channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

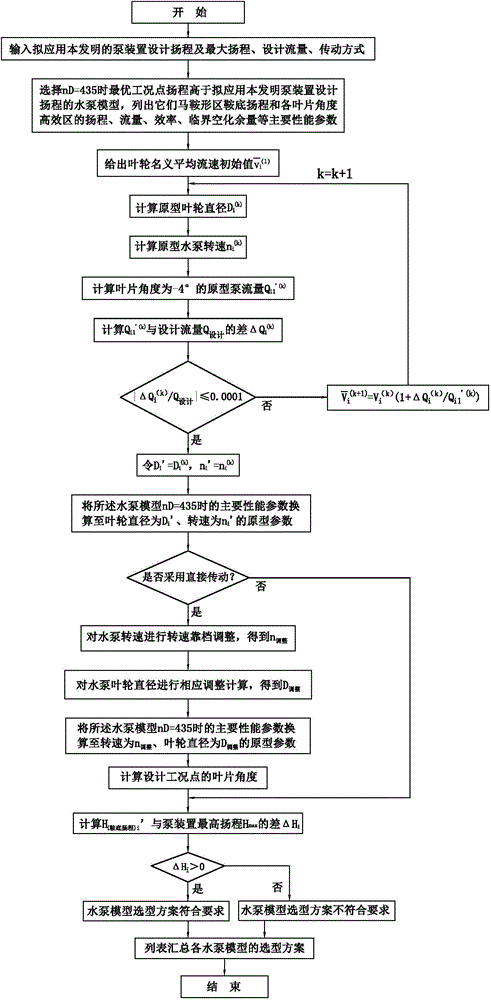

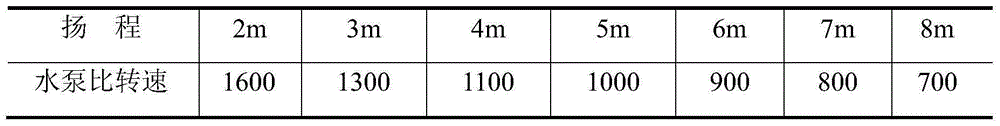

Method used

Image

Examples

Embodiment 1

[0079] Example 1 A large-scale low-lift pump device adopts indirect transmission, and the design lift is H 设计 =2.5m, the highest lift H max =4.01m, design flow Q 设计 =33.5m 3 / s. The steps of applying the present invention to carry out water pump type selection are as follows:

[0080] 1. Select the commonly used low-lift water pump models whose head in the high-efficiency area is higher than the design head of the pump device in this embodiment, and their models are arranged in order of specific speed from small to large: TJ04-ZL-20 (i=1), TJ04-ZL -19(i=2), TJ04-ZL-06(i=3) and TJ04-ZL-07(i=4), Table 2 lists the saddle bottom of the saddle area of these 4 water pump models when nD=435 Head (H 鞍底扬程 ) i And the head, flow rate, efficiency, critical cavitation margin and other main performance parameters of the optimal working point of each blade angle;

[0081] Table 2 The main performance parameters of the pump model whose head in the high-efficiency zone is higher than...

Embodiment 2

[0115] Example 2 A large-scale low-lift pump device adopts direct drive, and the design lift is H 设计 =3.75m, the highest lift H max =5.6m, design flow Q 设计 =33.5m 3 / s. The steps of applying the present invention to carry out water pump type selection are as follows:

[0116] 1. Select the commonly used low-lift water pump models whose head in the high-efficiency area is higher than the design head of the pump device in this embodiment, and their models are arranged in order of specific speed from small to large: TJ04-ZL-20 (i=1), TJ04-ZL -19 (i=2), TJ04-ZL-06 (i=3), Table 2 lists the saddle bottom head (H 鞍底扬程 ) i And the head, flow rate, efficiency, critical cavitation margin and other main performance parameters of the optimal working point of each blade angle;

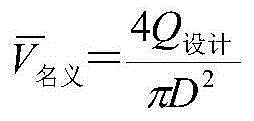

[0117] 2. Give the initial value of the nominal mean velocity of the impeller:

[0118] 3. Carry out iterative calculations for the selected three water pump models in turn. The iterative calculation formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com