Injection-molded part vacuum lamination decoration forming structure and method

A technology for forming structures and injection molded parts, which is applied in the automotive field and can solve problems such as inability to complete scrapped products and small demoulding slopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

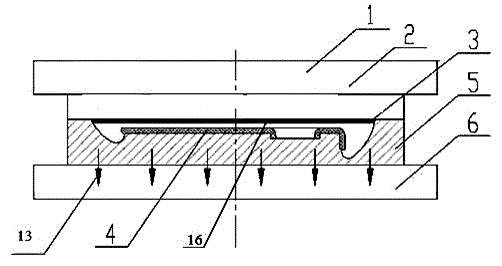

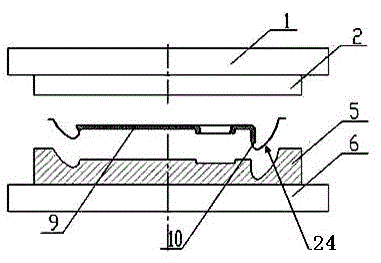

[0023] A vacuum film-coated decorative molding structure for injection molded parts, characterized in that it includes a lower template assembly, the lower template assembly includes a lower template, the lower template includes a lower platen, and the lower template includes an upper template assembly. The upper template assembly includes an upper template, an upper pressing plate is included above the upper template, an extrusion space is included between the upper template and the lower template, a groove is included above the lower template, and the upper template assembly and the lower template assembly can move relatively. The substantive technical effect and the realization process of the technical solution here are as follows: the upper template assembly and the lower template assembly can move rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com