A self-adjusting hydraulic brake caliper assembly

A hydraulic braking and self-adjusting technology, which is applied in the field of brake calipers, can solve the problems of small return stroke, large brake disc end face jump, failure, etc., to achieve the effect of controlling the braking distance and ensuring the braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

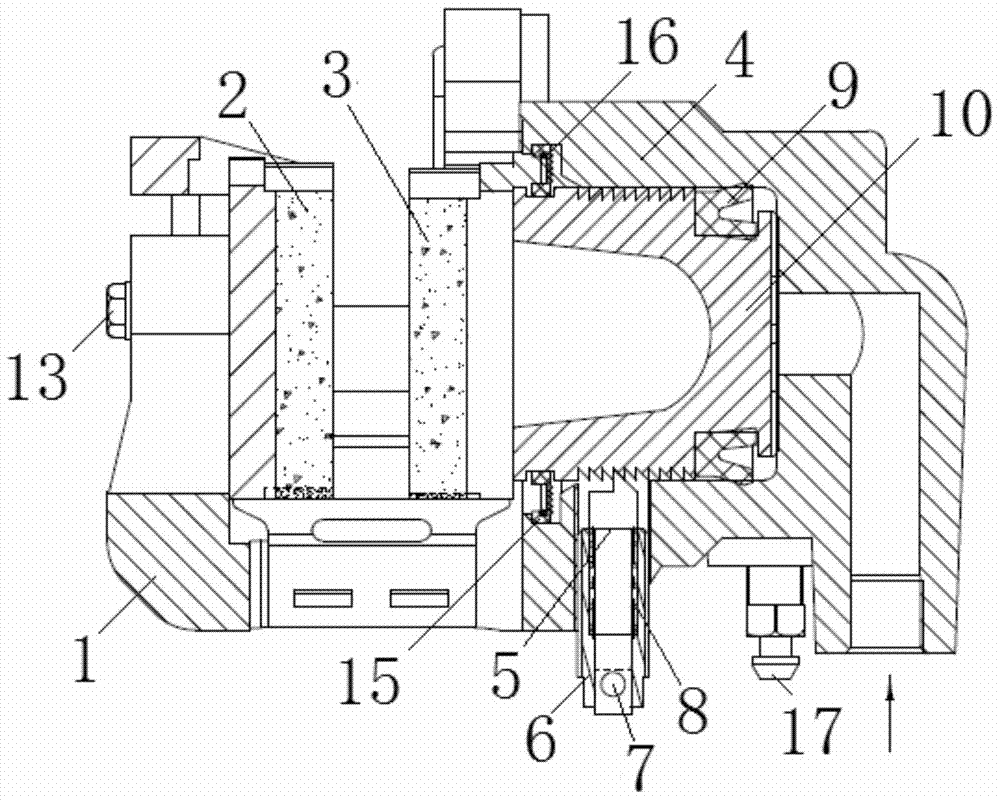

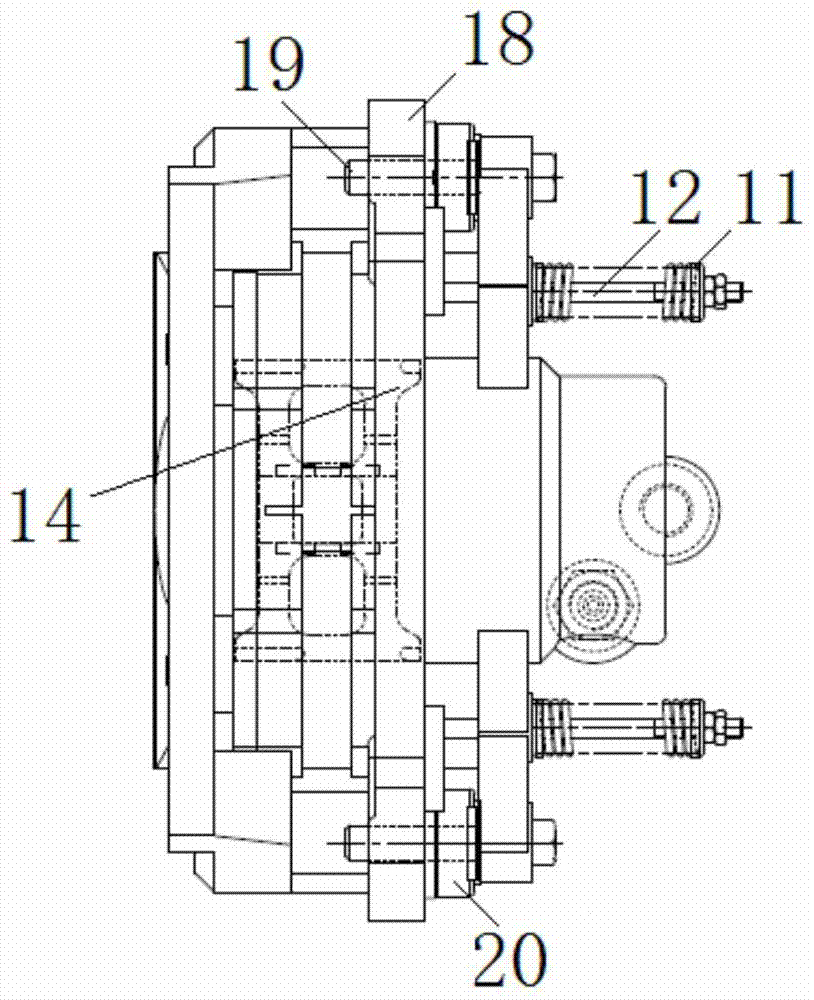

[0021] Such as figure 1 and figure 2 As shown, the self-adjusting hydraulic brake caliper assembly includes a caliper body 1, a bracket 18 and a self-adjusting mechanism, wherein the caliper body 1 is provided with dynamic friction plates 3 and static friction plates 2 located on both sides of the brake disc, and the caliper There is a hydraulic cylinder 4 on one side of the moving friction plate on the body, and a piston 10 is arranged inside the hydraulic cylinder 4, and a double-lip apron 9 is installed on the inner end of the piston, and the piston is pushed to the side under the pressure of the transmission fluid. Movement in the direction of the cylinder mouth pushes the dynamic friction plate to the brake disc. At the same time, the reaction force moves the caliper body backward, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com