Single piece wet cleaning method

A wet-cleaning, monolithic technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as liquid residue, affecting chip performance, and deionized water cannot be dried.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be further described below in conjunction with the accompanying drawings. Of course, the present invention is not limited to this specific embodiment, and general replacements known to those skilled in the art are also covered within the protection scope of the present invention.

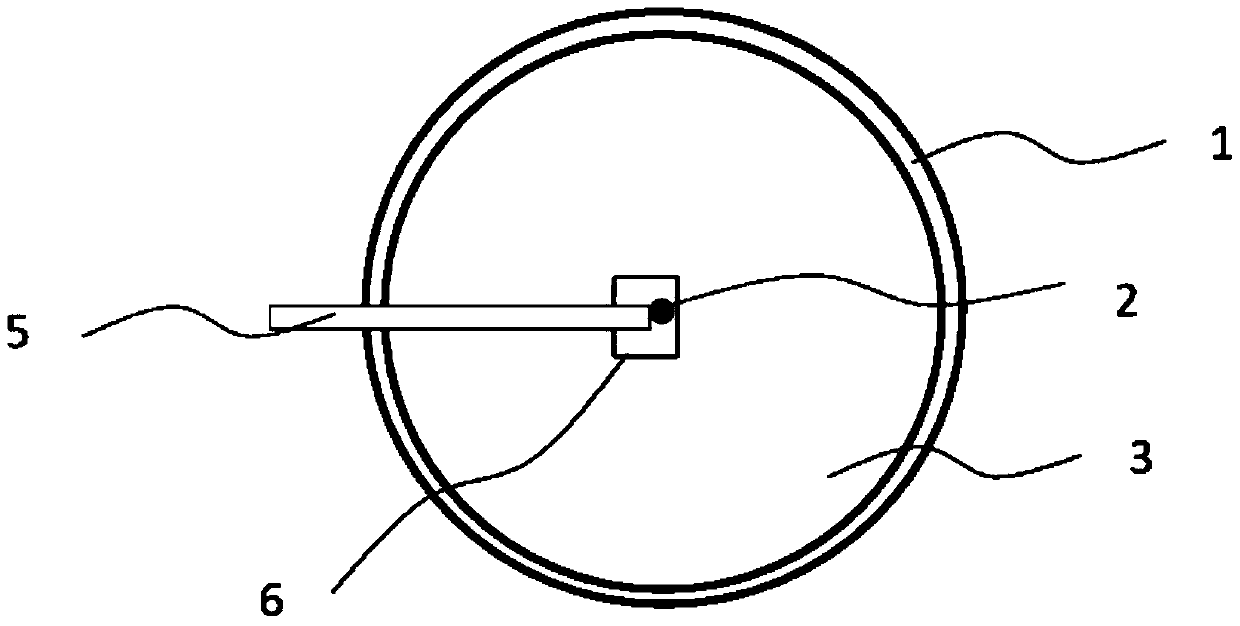

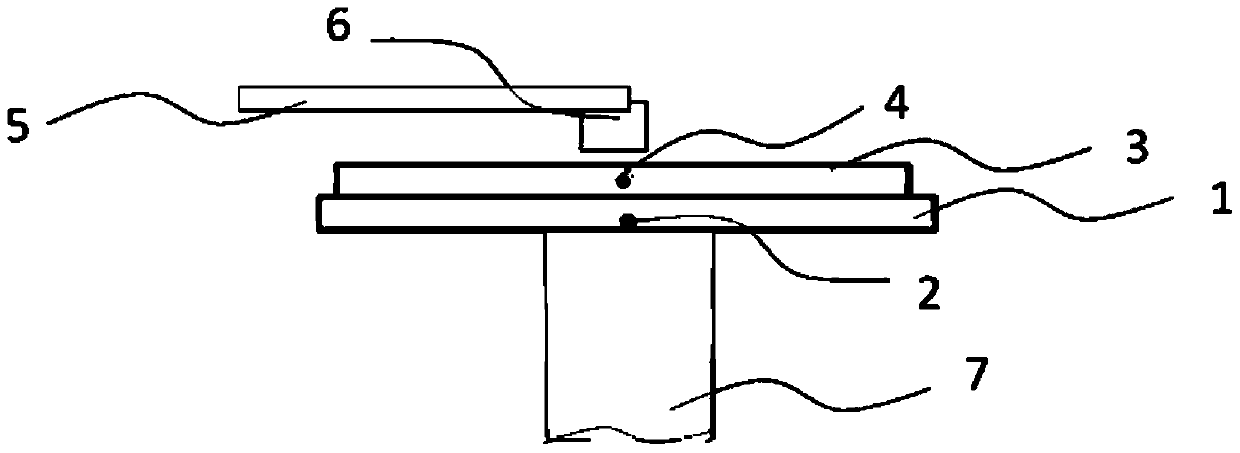

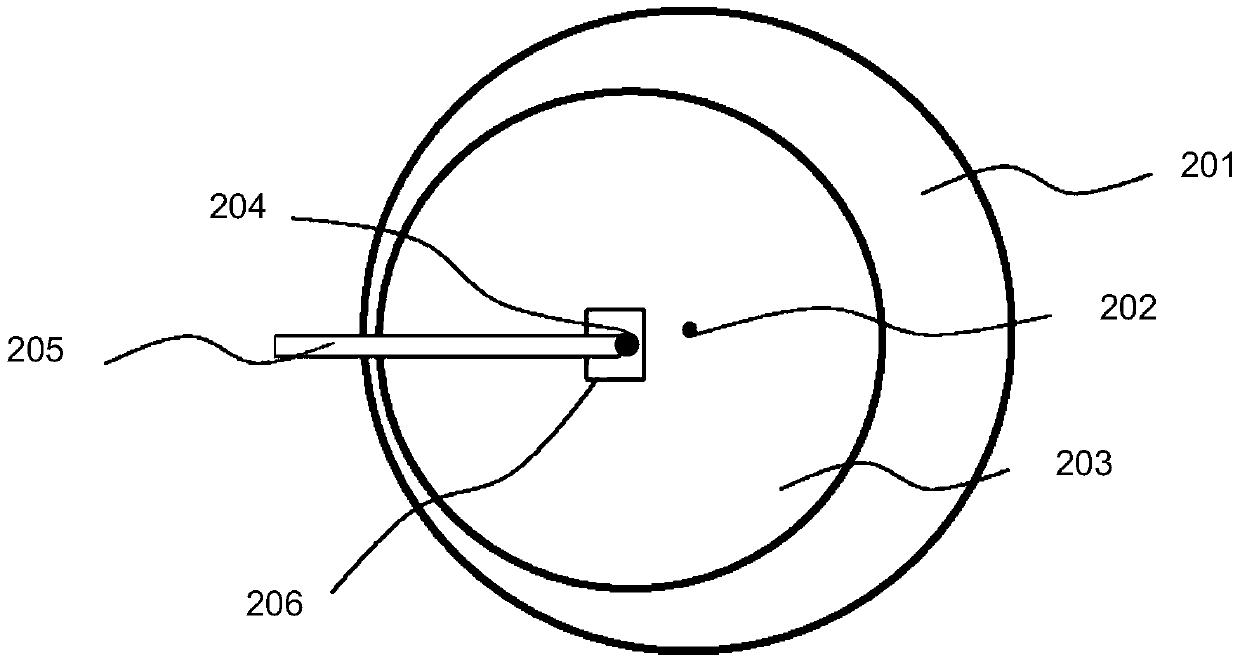

[0030] The single-piece wet cleaning method of the present invention will be further described in detail below in conjunction with accompanying drawings 2-4 and specific embodiments. It should be noted that the drawings are all in a very simplified form, using imprecise scales, and are only used to facilitate and clearly achieve the purpose of assisting in describing the present embodiment.

[0031] For this example, see Figure 2a and 2b , the single-chip wet cleaning equipment used has a rotary platform 201 for driving the wafer 203 to rotate, the rotary platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com