Process for preparing strained fermented dairy product

A technology for fermented dairy products, de-milking, applied in dairy products, other dairy products, bacteria used in food preparation, etc., and can solve problems such as unsatisfactory taste, appearance and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] A dewhey fermented milk product is prepared according to the method of the present invention.

[0063] The product has the following characteristics.

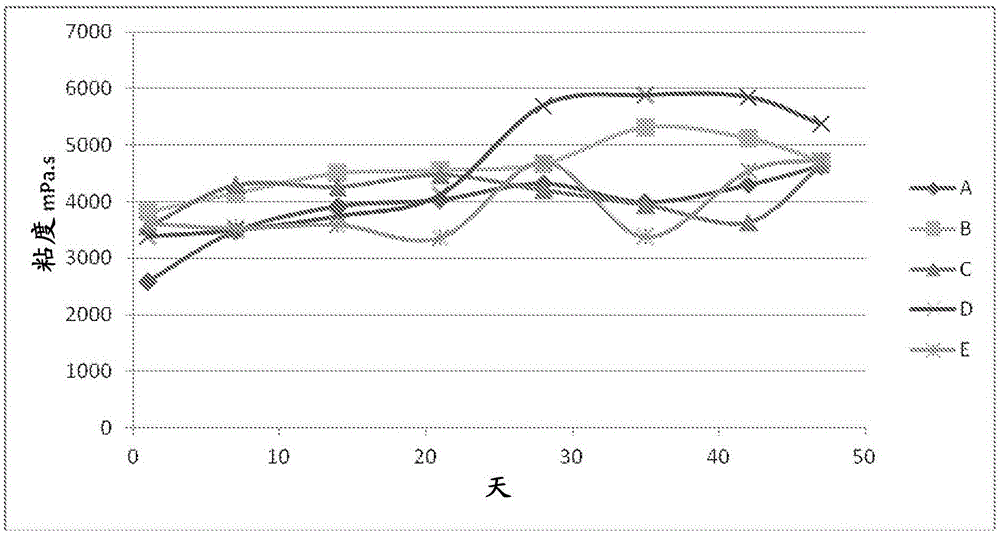

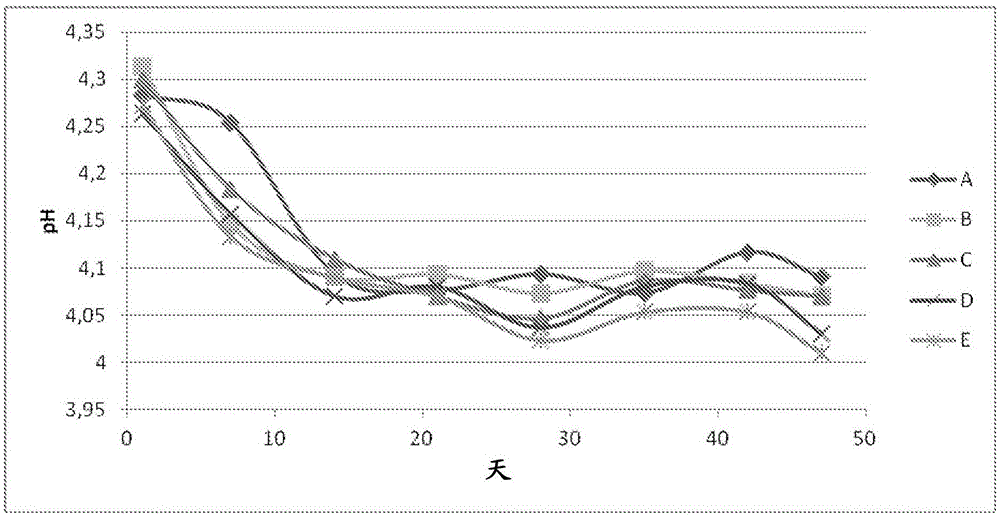

[0064] 1) Viscosity and pH of the whey-free fermented milk product prepared according to the present invention

[0065]

[0066] At a temperature of 10°C, the shear force is 64s -1 The viscosity was measured with a Rheomat RM 200.

[0067] pH was measured at 10°C with typical laboratory equipment.

[0068] The dornic acidity was measured by adding 0.1 N NaOH at 10 °C until pH 8.35.

[0069] The result is as figure 1 and figure 2 shown.

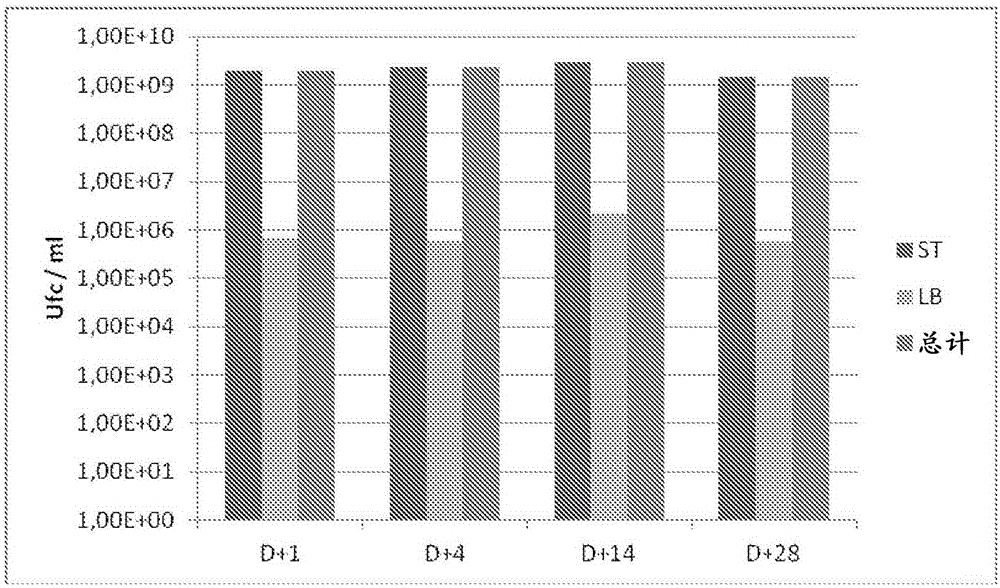

[0070] 2) Bacterial count (cfu / ml)

[0071] Bacteria counts were carried out on the whey-free fermented milk products prepared by the heat treatment step (at a temperature of 58° C. for 2.5 minutes) following the fermentation step.

[0072] If so image 3 shown.

[0073] 3) Sensory Spectrum

[0074] The inventive deheyed fermented milk product (X) and the commercial dehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com