Automobile back-row seat cushion framework assembly

A technology for rear seats and cushion frames, which is applied to seat frames and other directions, can solve the problems of low skeleton strength, high precision requirements, and can not meet the requirements of new regulations, and achieves the goal of reducing precision requirements, simplifying structure, and improving skeleton strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

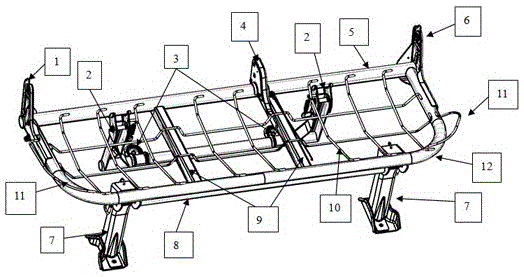

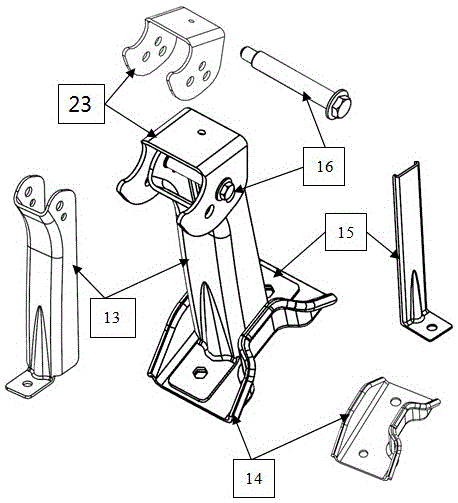

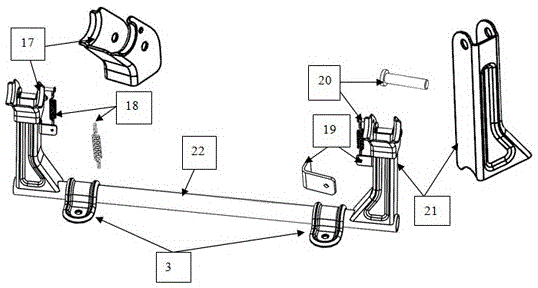

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] Figure 1 to Figure 3 The reference numerals in the figure are: seat cushion right connecting plate 1; rear supporting foot assembly 2; seat cushion mounting bracket 3; backrest limiter connecting plate 4; seat cushion rear support pipe 5; seat cushion left connecting plate 6; front supporting foot assembly 7; Front support foot reinforcement tube 8; seat cushion support longitudinal beam 9; cushion bottom surface grid assembly 10; cushion side grid assembly 11; cushion tube frame 12; front foot support plate 13; front foot mounting seat 14; installation foot reinforcement plate 15; front rotation Pin 16; Rear foot support seat 17; Hanging spring 18; Hanging spring support 19; Rear rotation pin 20; Rear foot support plate 21;

[0022] Such as Figure 1 to Figure 3 As shown, a rear seat cushion skeleton assembly of an automobile include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com