Broken chain monitoring and protecting system for scraper conveyor

A technology of scraper conveyor and protection system, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

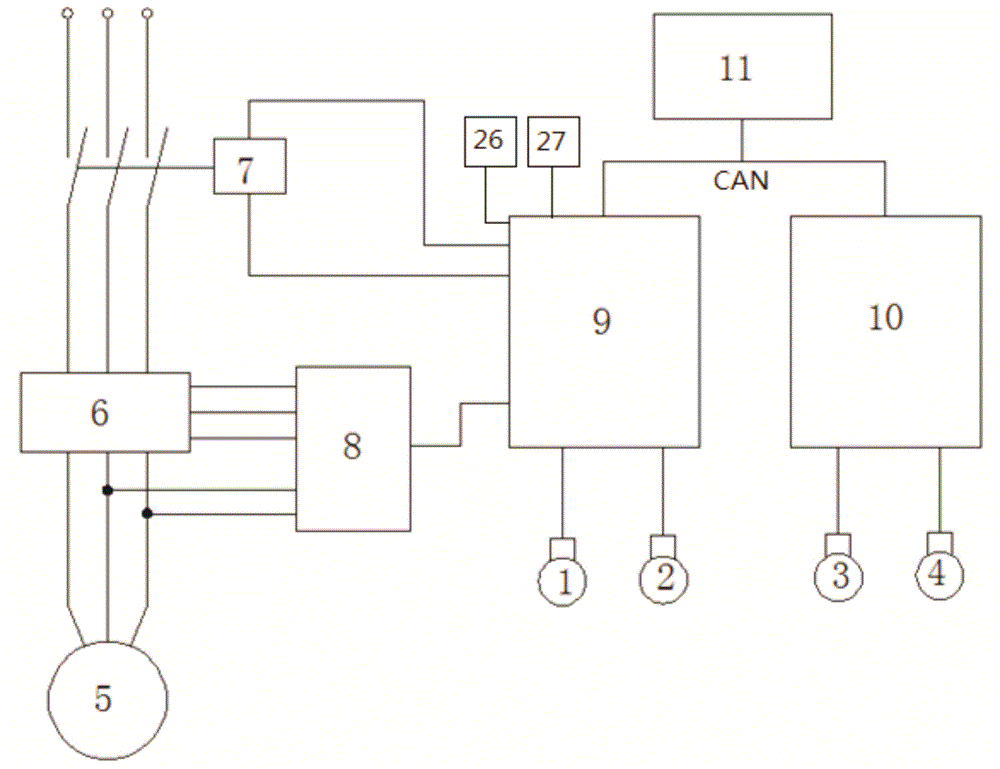

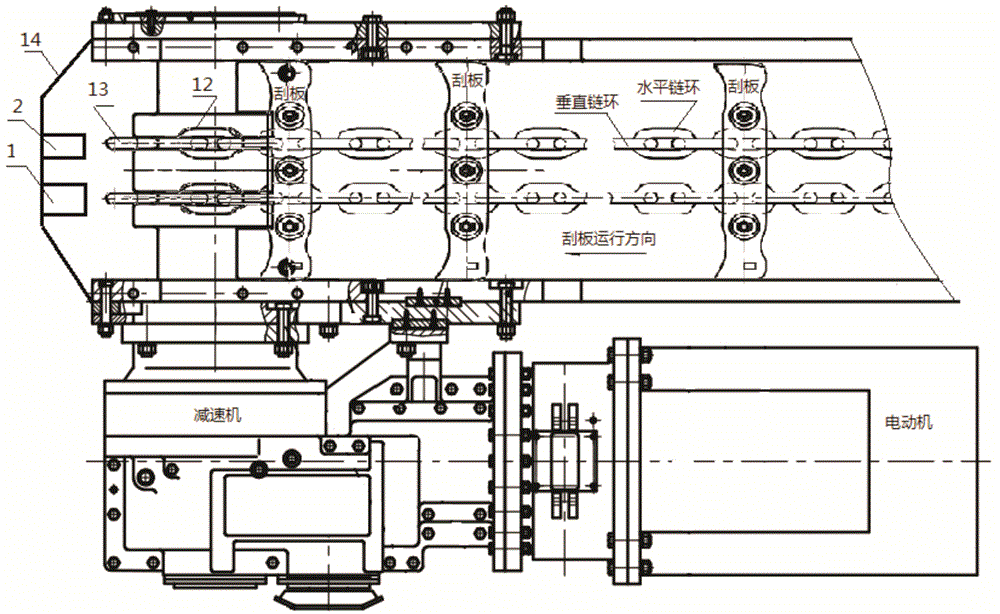

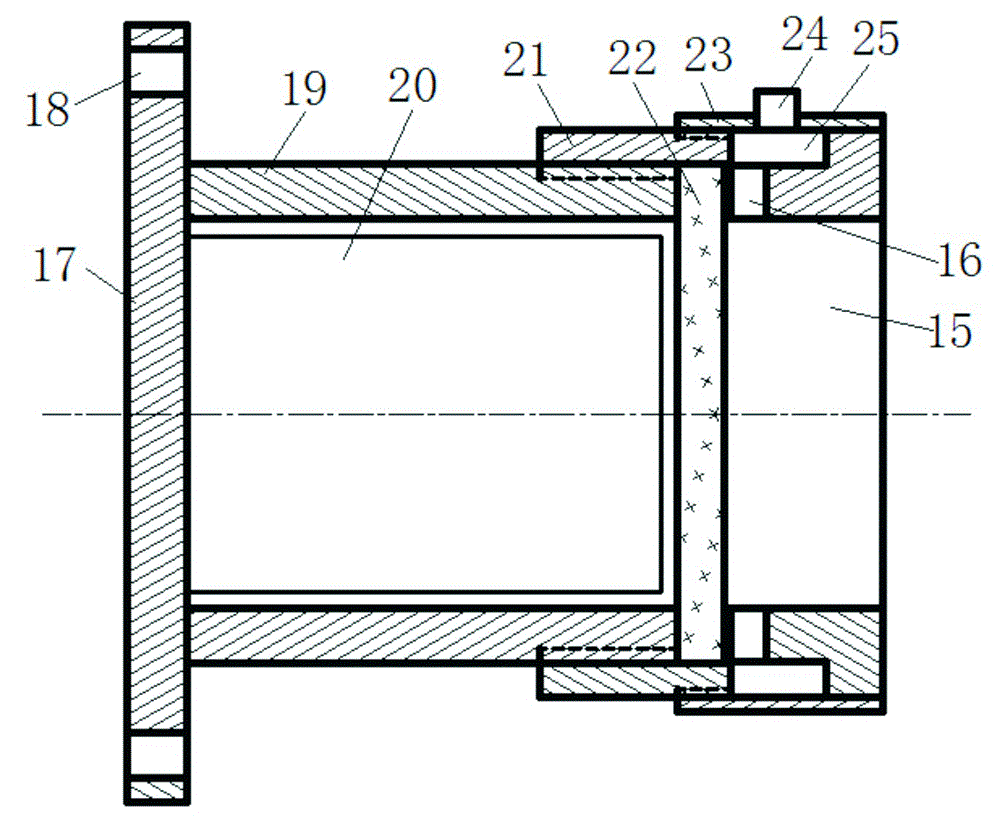

[0013] Now refer to the attached figure 1 , attached figure 2 And attached image 3 , are described as follows in conjunction with the embodiments: A chain-breaking monitoring and protection system for scraper conveyors according to the present invention includes a machine head infrared sensor A1, a machine head infrared sensor B2, a machine tail infrared sensor A3, a machine tail infrared sensor B4, a motor 5. Current transformer 6, magnetic starter 7, electrical parameter acquisition module 8, machine head controller 9, machine tail data transmission module 10, monitoring host 11, horizontal link 12, vertical link 13, bracket 14, air chamber 15. Air hole 16, base 17, mounting hole 18, sheath 19, explosion-proof infrared sensor 20, cover 21, glass 22, airway envelope 23, air inlet nozzle 24, airway 25, start button 26 and stop button 27. The magnetic starter 7 is connected to the motor 5 through the current transformer 6, the current transformer 6 is connected to the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com