Automatic monitoring equipment for annular pressure of oil field gas well

An annulus pressure, automatic monitoring technology, applied in flushing wellbore, wellbore/well components, measurement, etc., can solve problems such as unreasonable selection or formula design, low replacement efficiency, failure of cement sheath seal, etc., to achieve safety The effect of efficient production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

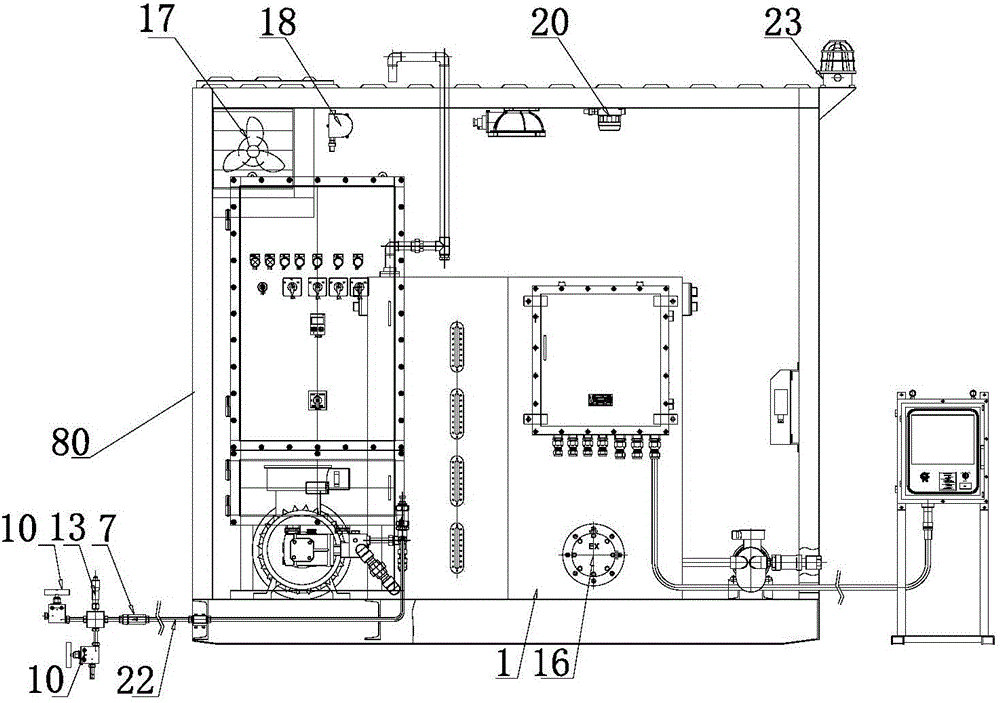

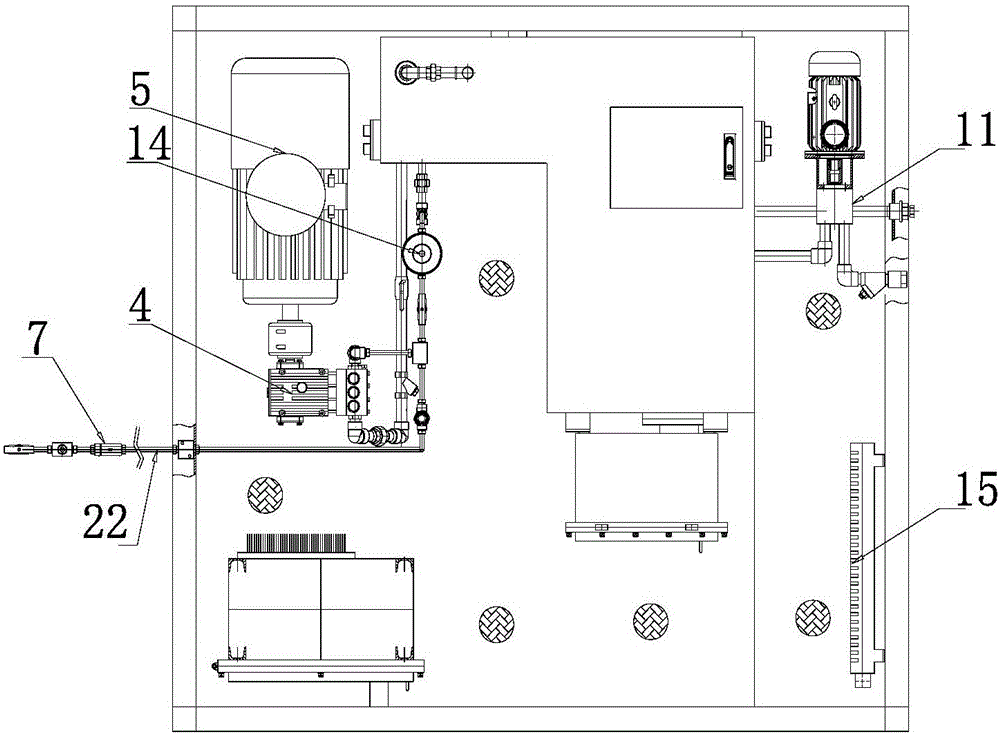

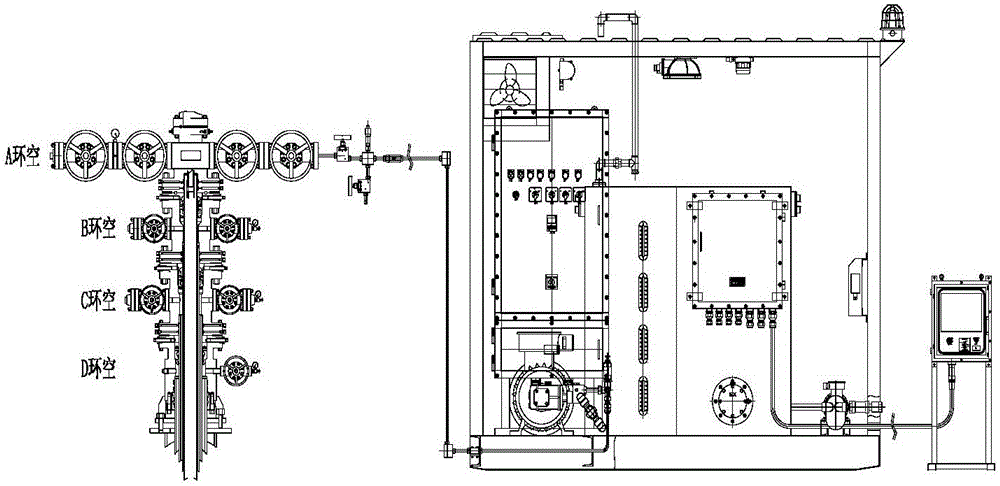

[0022] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

[0023] See Figure 1 to Figure 3 , the present invention relates to an oil field gas well annular pressure automatic monitoring equipment, and its preferred embodiment includes a controller, a pressure sensor 13, a booster mechanism and a liquid storage tank 1 for storing annular protection fluid;

[0024] The pressure sensor 13 is used to detect the pressure of the annulus of the gas well in the oil field in real time, and generate a corresponding annulus pressure signal;

[0025] The controller is used to compare the annular pressure signal with the preset pressure lower limit threshold, and when the annular pressure signal is lower than the pressure lower limit threshold, the oil annulus protection fluid in the liquid storage tank 1 is replenished to the The annulus of the gas well in the oil field is pressurized until the pressure signal of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com