Intermediate bearings with hydraulic loading devices for ship propulsion shafting test rigs

A technology of hydraulic loading and intermediate bearings, which is applied in the direction of mechanical bearing testing, etc., to achieve the effect of perfecting test and testing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

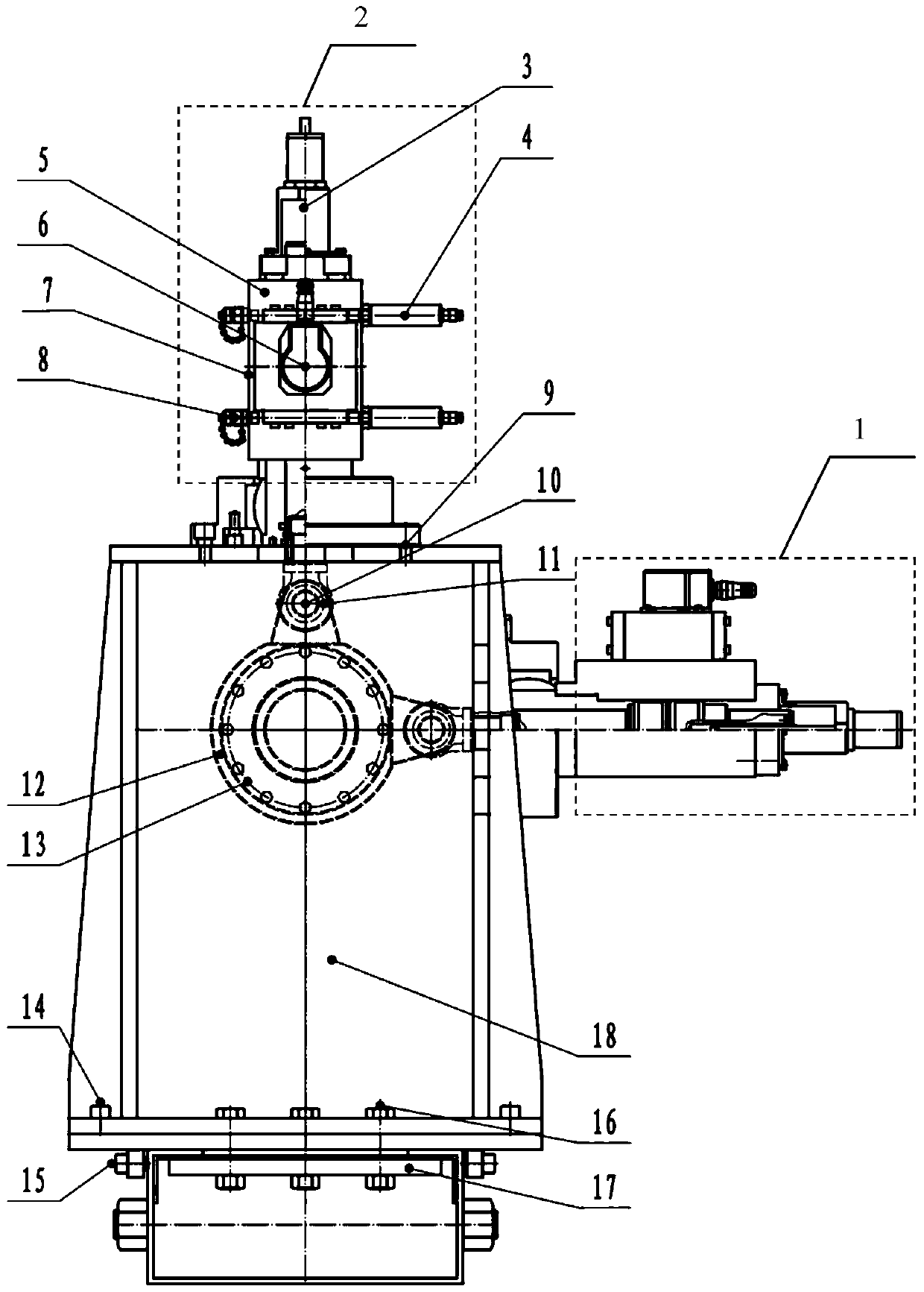

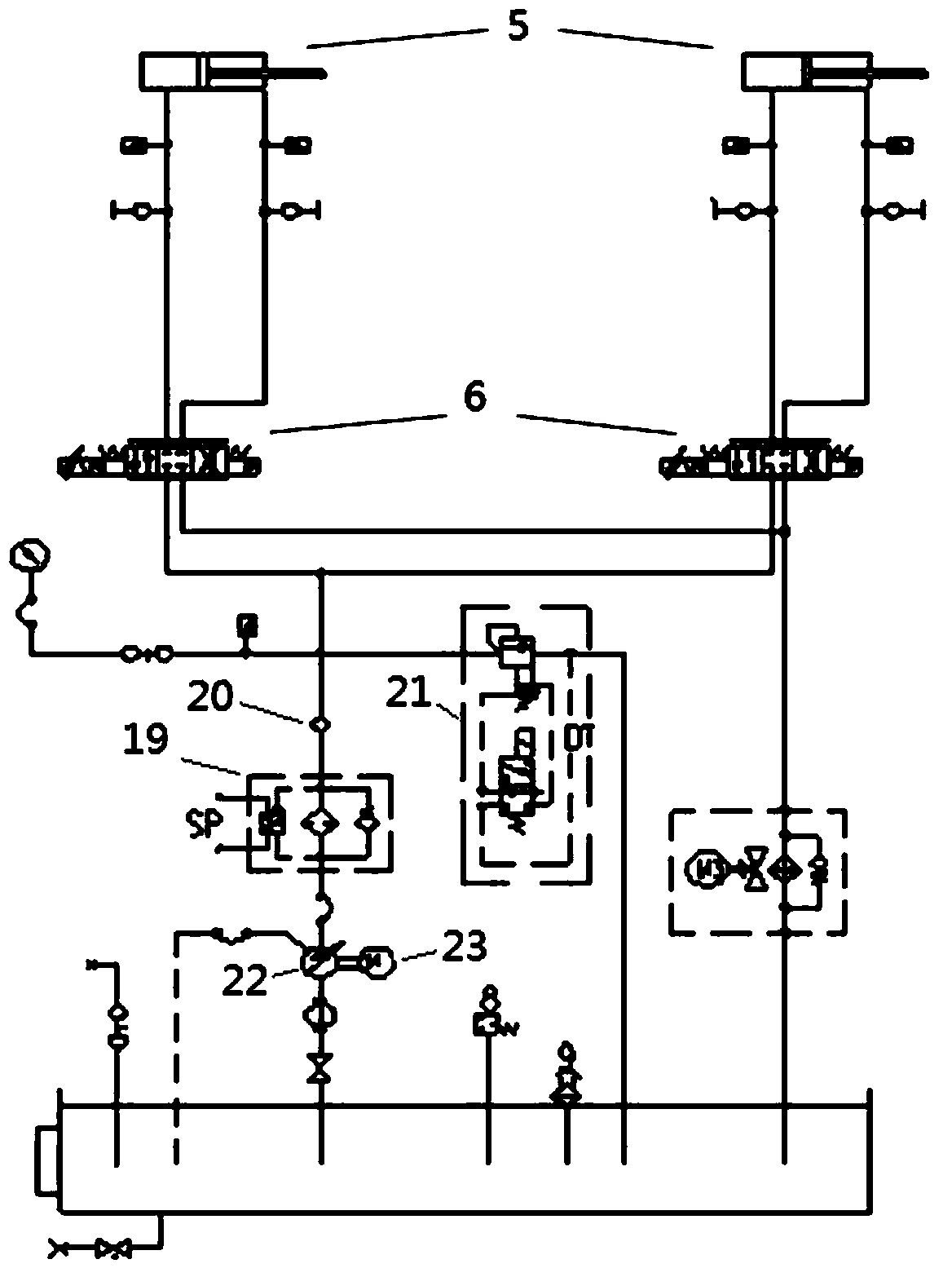

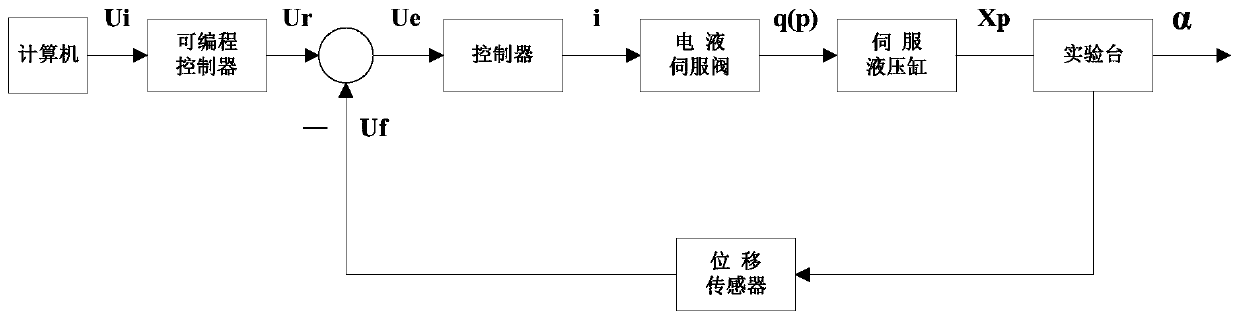

[0026] The invention provides an intermediate bearing with a hydraulic loading device for a ship propulsion shafting test bench. The loading device attached to the intermediate bearing is mainly composed of a force loading hydraulic device, a force sensor detection unit, a displacement sensor detection unit, and a hydraulic loading system controller. The force-loading hydraulic device has two hydraulic circuits, which are respectively installed in the horizontal and vertical directions of the intermediate bearing on the propulsion shafting of the ship. The oil cylinder is used for loading. The two hydraulic circuits can act separately or be adjusted at the same time. The pressure sensor detects the magnitude of the pressure, and the displacement sensor detects the moving distance of the shaft, so as to realize the closed-loop control, and carry out the conventional periodic function displacement loading on the bearing to simulate the effect of the hull deformation on the propul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap