Brake control system with adaptive lining characteristic curve for rail vehicles

A characteristic curve, rail vehicle technology, applied in the operation mechanism of rail vehicle brake, railway brake system, ABS control system, etc., can solve the problems of limitation, increase technical cost, etc., and achieve the effect of simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

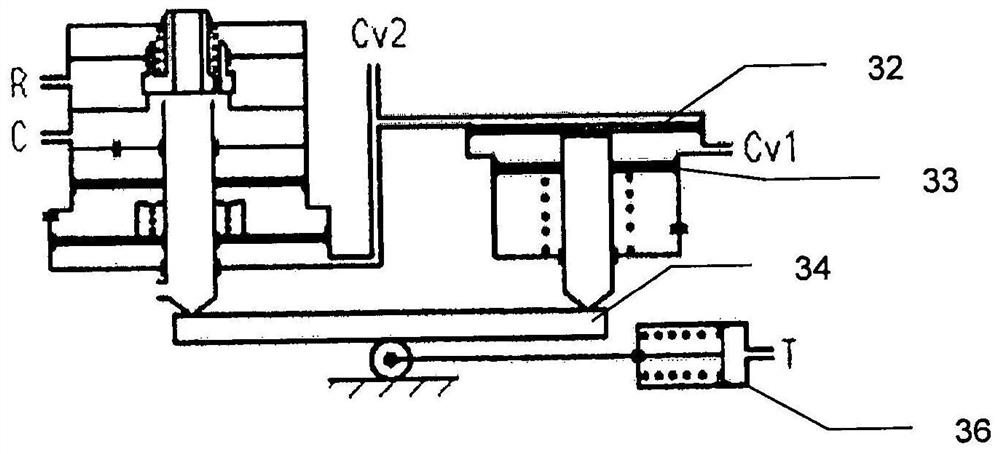

[0021] Advantageous embodiments for providing a friction coefficient-compensated brake control pressure for a pneumatic brake of a rail vehicle are described below with reference to an exemplary brake device for a rail vehicle.

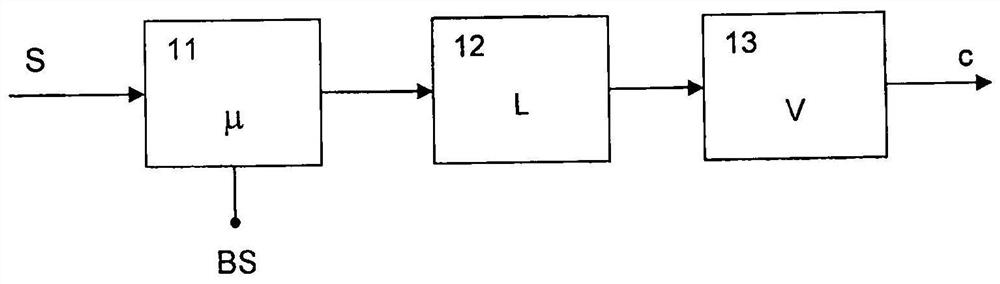

[0022] figure 1 A schematic functional block diagram of the brake control system according to the first exemplary embodiment is shown.

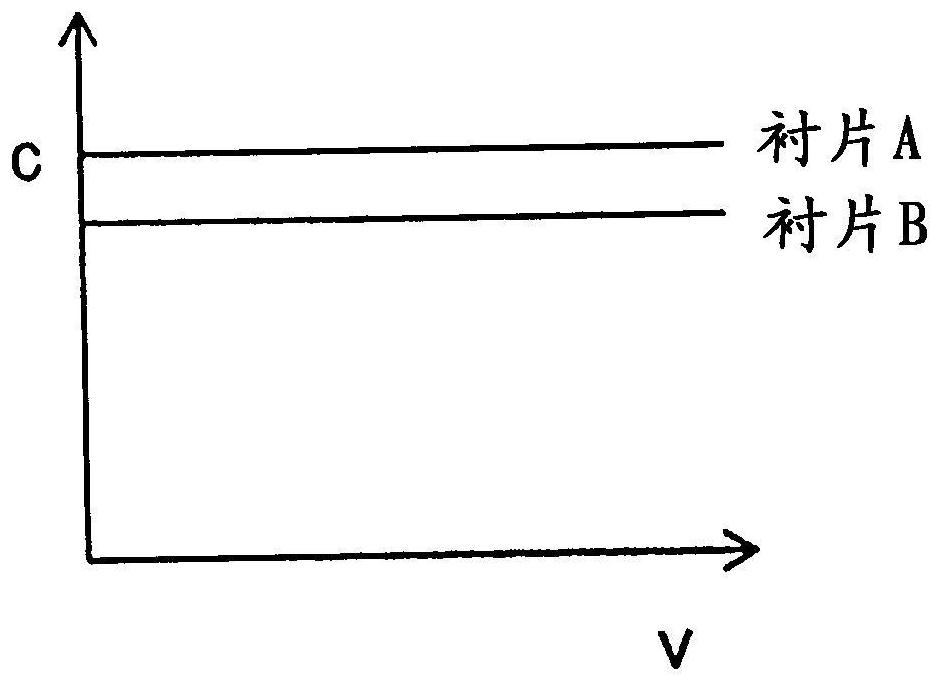

[0023] According to a first embodiment, the load pressure regulating, limiting or relay valve is designed to be independent of the load correction (L) of the brake pressure c by means of the corresponding load correction unit (L) 12 , for example during rapid braking , the pressure characteristic curve is additionally changed (for example shifted) by increasing the volume by means of booster unit (V) 13 in order to compensate for changes in the coefficient of friction caused by changing the type of brake lining. For this, a coefficient of friction determination or coefficient of friction adaptation unit 11 is first ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap