Fluid Dispensing System and Reservoir

A liquid storage and fluid technology, applied in the field of liquid storage, can solve problems such as insufficient supply and fluid supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

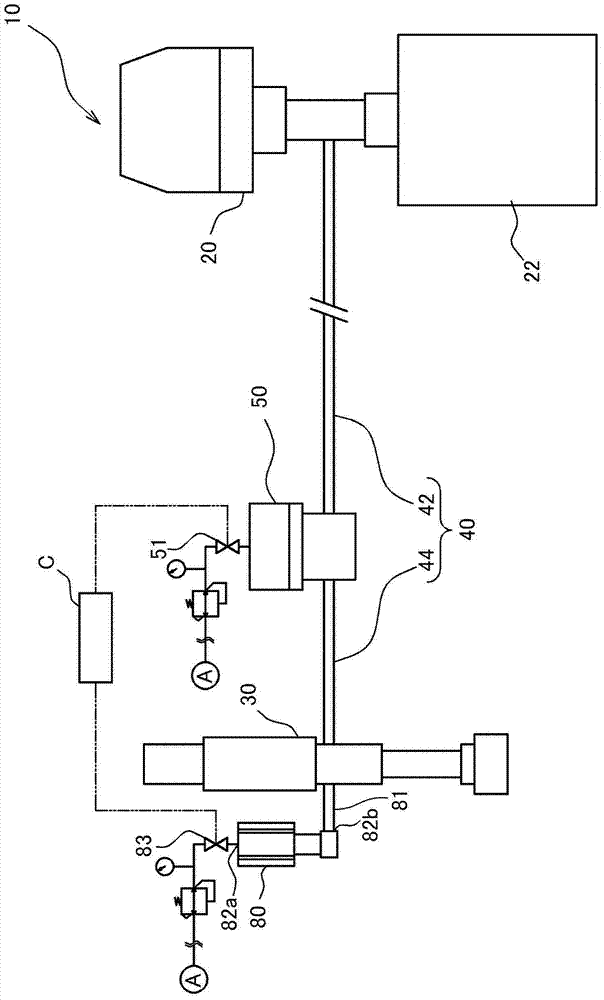

[0052] Hereinafter, a fluid discharge system 10 according to an embodiment of the present invention will be described with reference to the drawings.

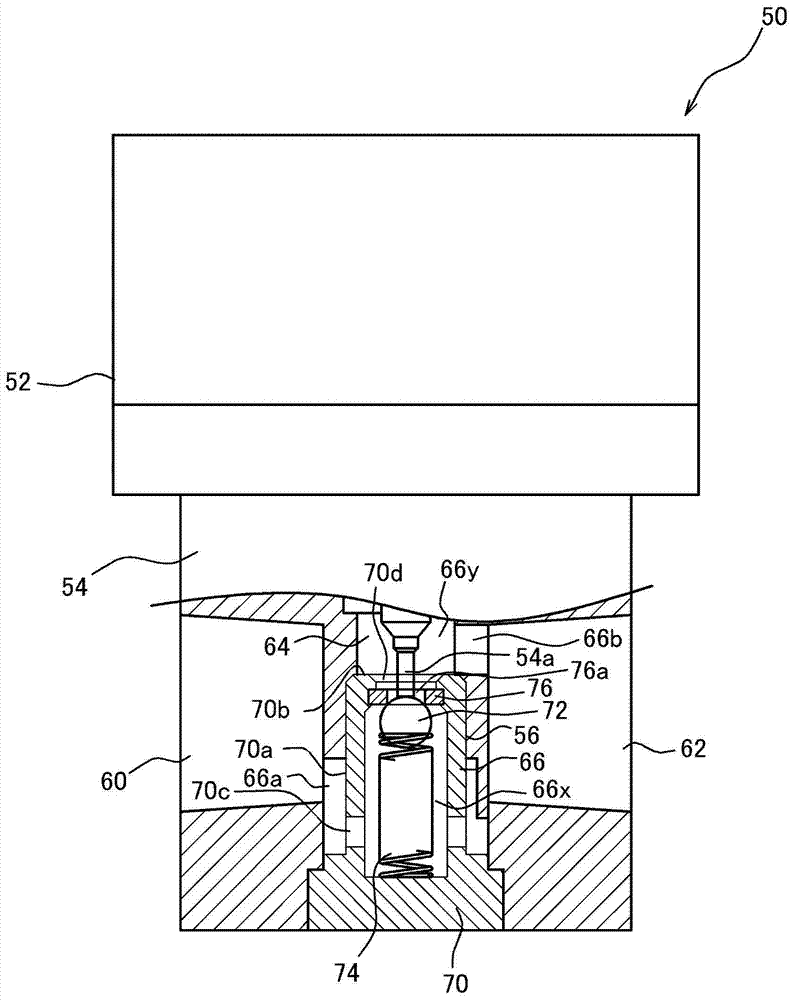

[0053] Such as figure 1 As shown, the fluid discharge system 10 is configured to connect the supply device 20 and the discharge device 30 through the supply channel 40 . In addition, the fluid discharge system 10 is configured such that a regulator 50 is provided at an intermediate position of the supply channel 40 and an accumulator 80 is attached to the discharge device 30 . The fluid discharge system 10 is a system for discharging the fluid supplied from the supply device 20 from the discharge device 30 onto a workpiece.

[0054] The supply device 20 is a device for sucking a fluid from a storage portion 22 storing the fluid and feeding the fluid under pressure. The supply device 20 is connected to the supply channel 40 through a pipe. Therefore, the fluid sucked from the reservoir by the supply device 20 can be pressuri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap