Moulding body and method for production thereof

A body, molding material technology, applied in the direction of processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve problems such as high investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

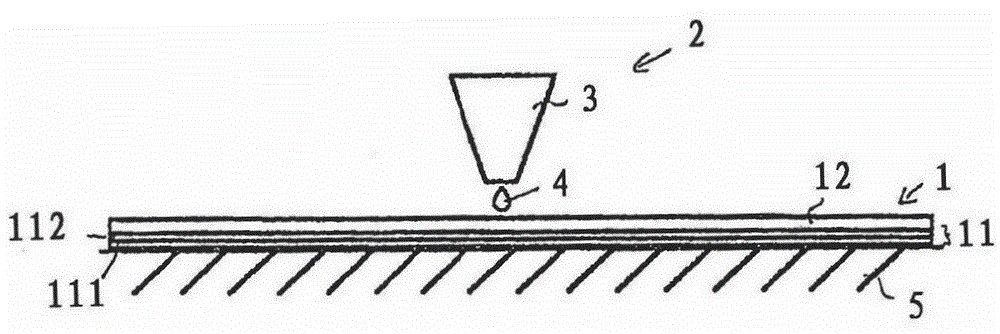

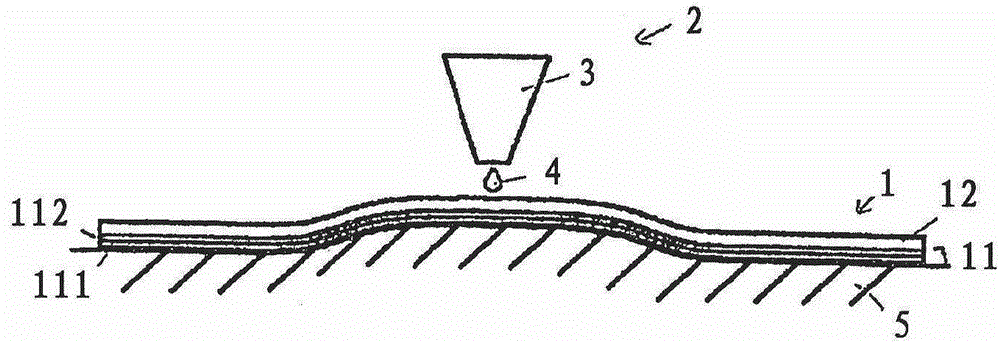

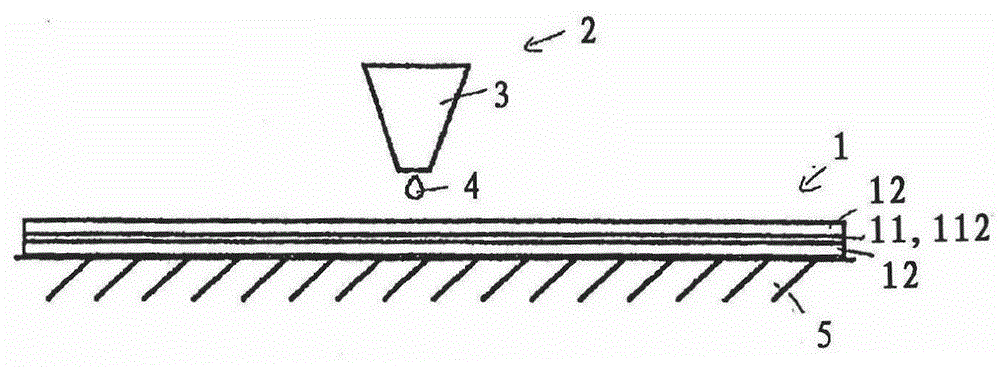

[0073] The molded body 1 comprises a foil layer 11 to which a plastic molding material 12 is applied by means of three-dimensional printing.

[0074] In this example, the foil layer 11 may be a laminate foil or a transfer foil. In the latter case, the foil layer 11 comprises a carrier layer 111 to which is adhered a transfer layer 112 which ultimately remains in the molded body, so that it is detachable.

[0075] The layer thickness of the foil layer 11 is preferably 10 μm to 250 μm, more preferably 20 μm to 250 μm.

[0076] The foil layer 11 may have an adhesion promoting layer, which is not represented in the figures. Plastic molding material 12 is applied to this adhesion promoting layer. In this example, it could be a plastic and / or a heat-activated adhesive chemically related to the plastic molding material, for example, a polyvinyl chloride (PVC)-based or acrylic-based adhesive, or a PVC- and acrylic-based adhesive mixture of adhesives.

[0077] Furthermore, the foil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com