Scyphus hole insert, panel fixing piece and scyphus hinge

A technology of cups and inserts, which is applied in the directions of hinged plates, connecting components, wing leaf parts, etc., which can solve the problems of increasing labor costs and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

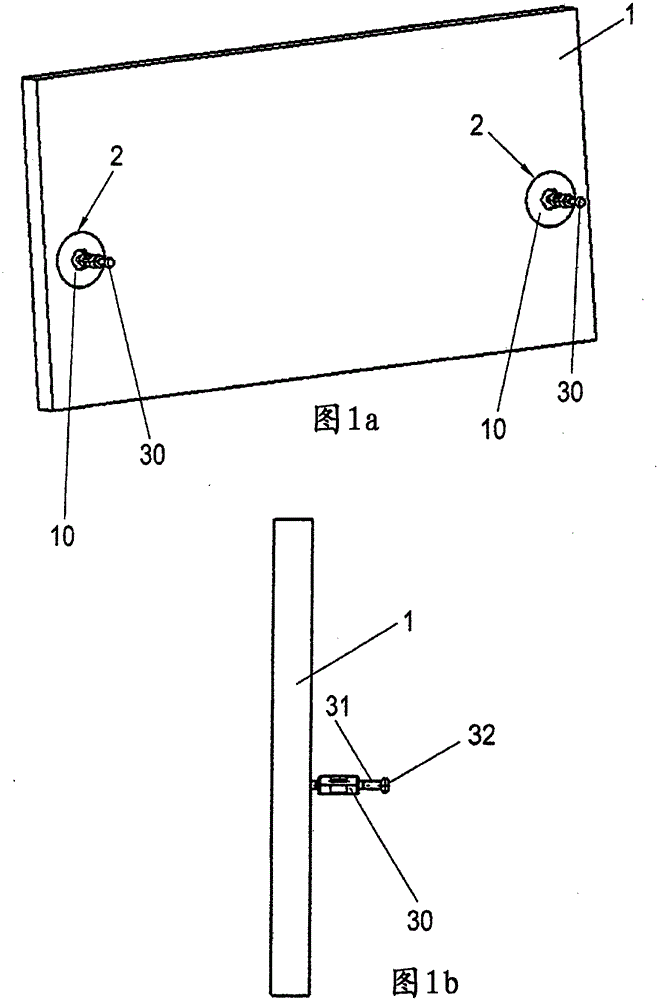

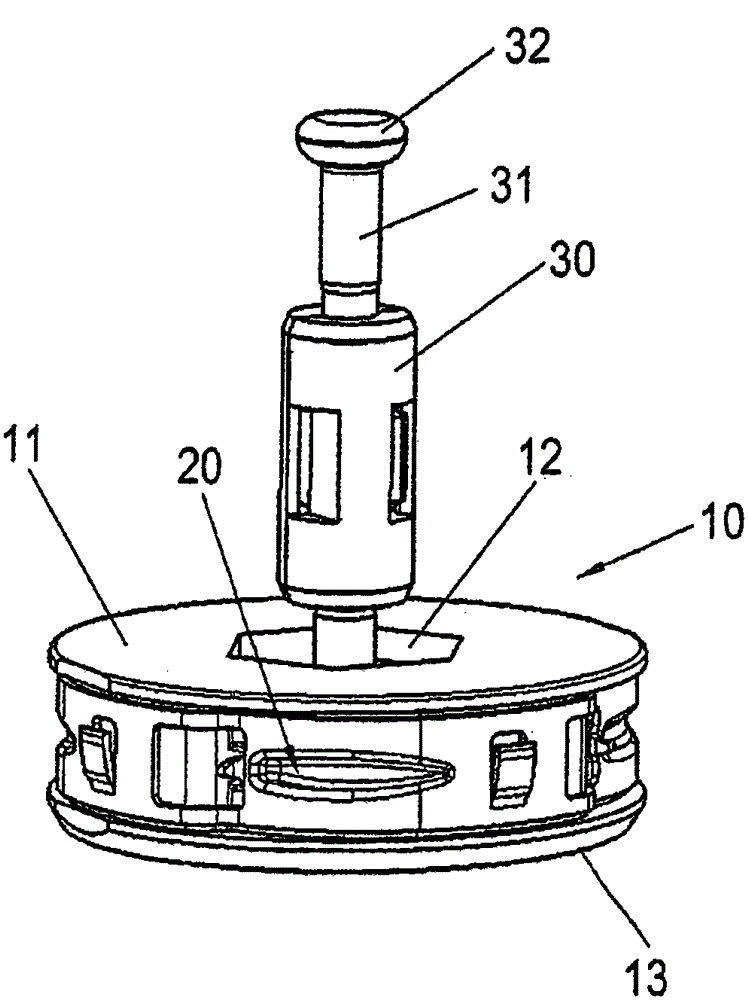

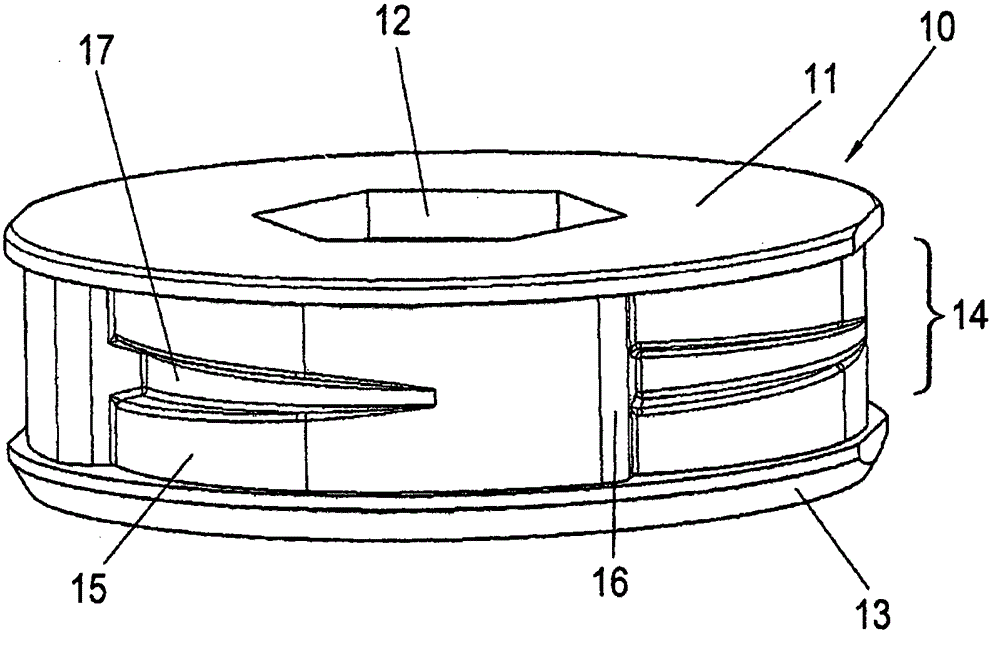

[0027] Figure 1a The back of the panel 1 facing away from the drawer is shown in isometric view. Such a panel 1 , also called a front panel, closes the drawer to the front and is usually fastened to the side frame of the drawer. For this purpose, cup bores 2 are drilled into the side panels 1 in the laterally outer region, into which a panel holder according to the application is inserted in each case. The panel fixing has a cup hole insert with a base body 10 which is flush-embedded in the cup bore 2 and fixed in the cup bore 2 in a manner described in detail below. The base body 10 has a pin 30 protruding perpendicular to the upper side of the base body 10 in the center, and the fixation with each side frame of the drawer is realized through the pins.

[0028] Figure 1b The panel 1 is shown in side view. It can be clearly seen from this side view that the base body 10 is completely inserted into the cup bore 2 and does not protrude from the surface of the panel 1 at any...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com