Assembled structure of ski resort and its construction method

A technology for ski resorts and snow tracks, which is applied to building structures, gymnasiums, buildings, etc., can solve the problems of inability to meet the assembly quality and precision requirements of plane or three-dimensional steel structures, low assembly efficiency, complex structures, etc., to meet the assembly quality requirements and accuracy requirements, flexible assembly method, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

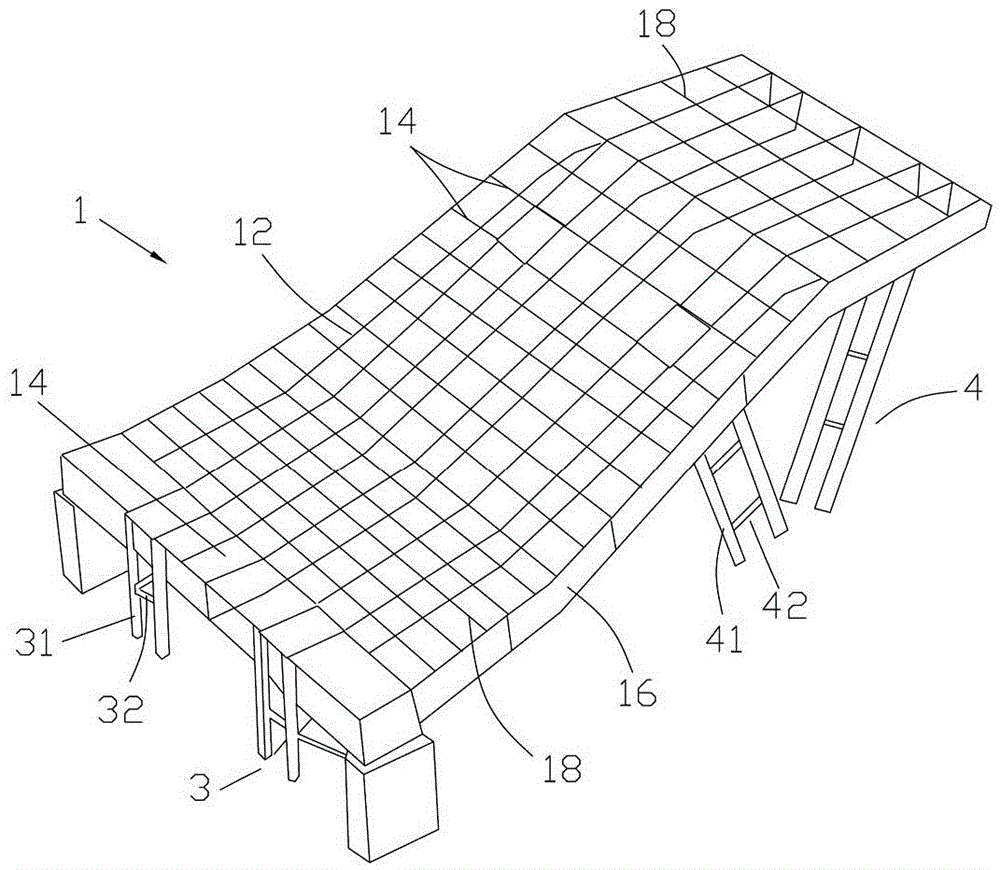

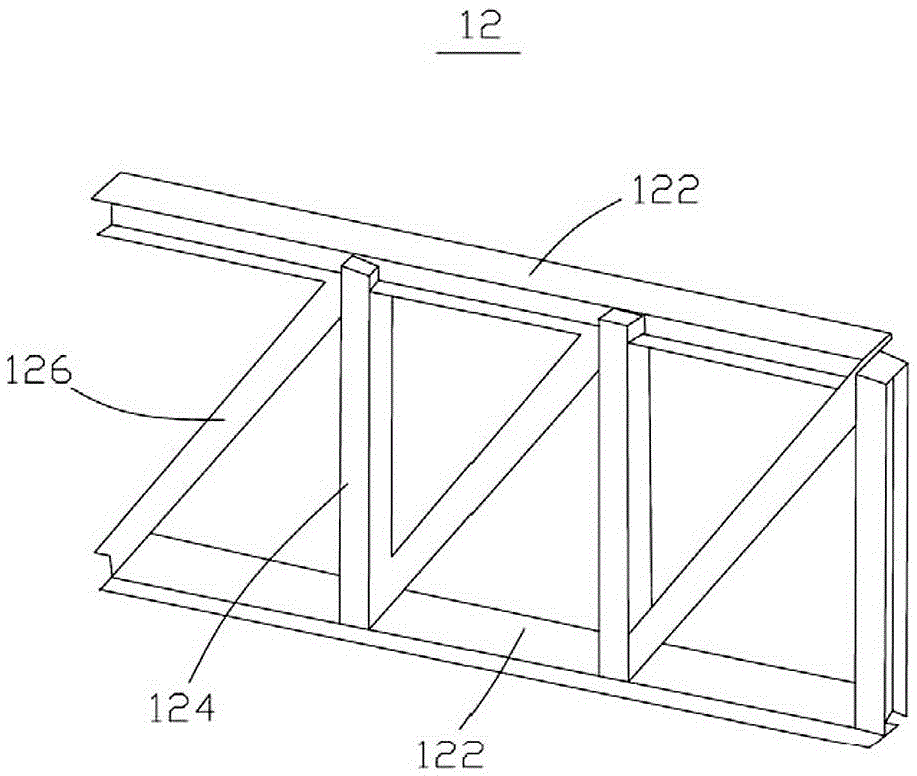

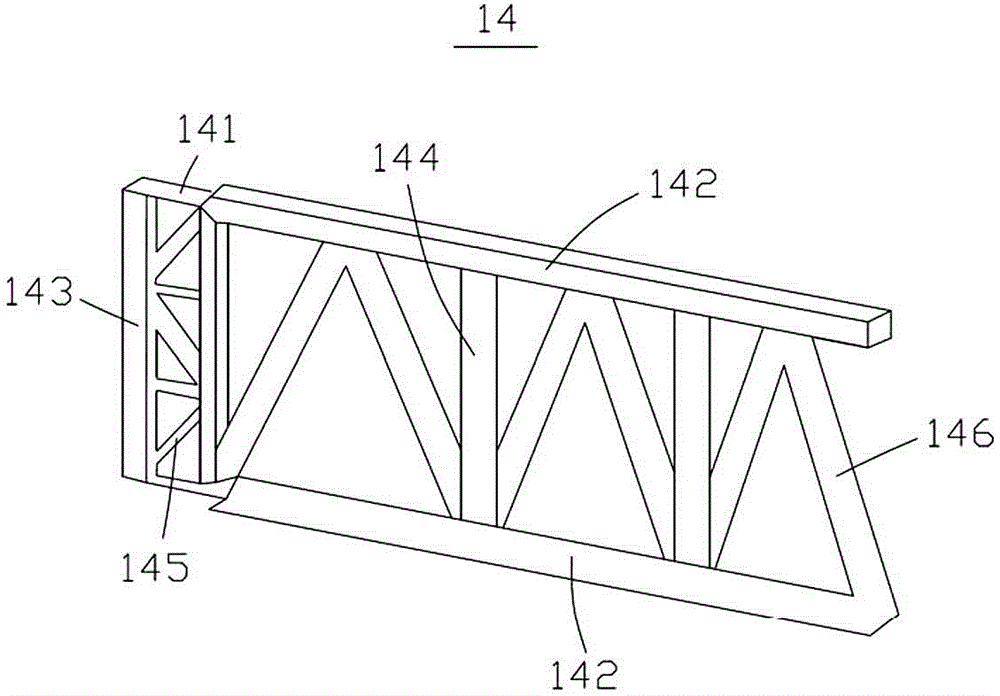

[0033] see figure 1 and Image 6 The ski resort assembly structure of the present invention includes a steel cylinder supported on the ground, a snow track layer steel truss 1 fixed on the steel cylinder, and a roof steel truss 2 welded and fixed to the snow track layer steel truss 1. The cylinder body includes straight columns 3 and inclined columns 4 oppositely arranged, and the steel truss 1 for the snow track layer includes a group of longitudinal main trusses 12 for the snow track layer, a group of transverse main trusses 14 for the snow track layer, and a group of longitudinal trusses for the snow track layer. Side trusses 16 and a group of snow track layer trusses 18, the snow track layer transverse main trusses 14 are respectively fixed on the straight column 3 and the inclined column 4 along the transverse direction, and the snow tr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap