Long shaft gear-assembled reducer

A technology for installing gears and reducers, which is applied to gear transmissions, belts/chains/gears, mechanical equipment, etc. It can solve problems that affect the performance and life of shafts, difficulty in installing gear sets, and long output shafts, etc., to achieve gear assembly Strong structure, convenient installation, improve the effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Further description will be made below in conjunction with drawings and embodiments.

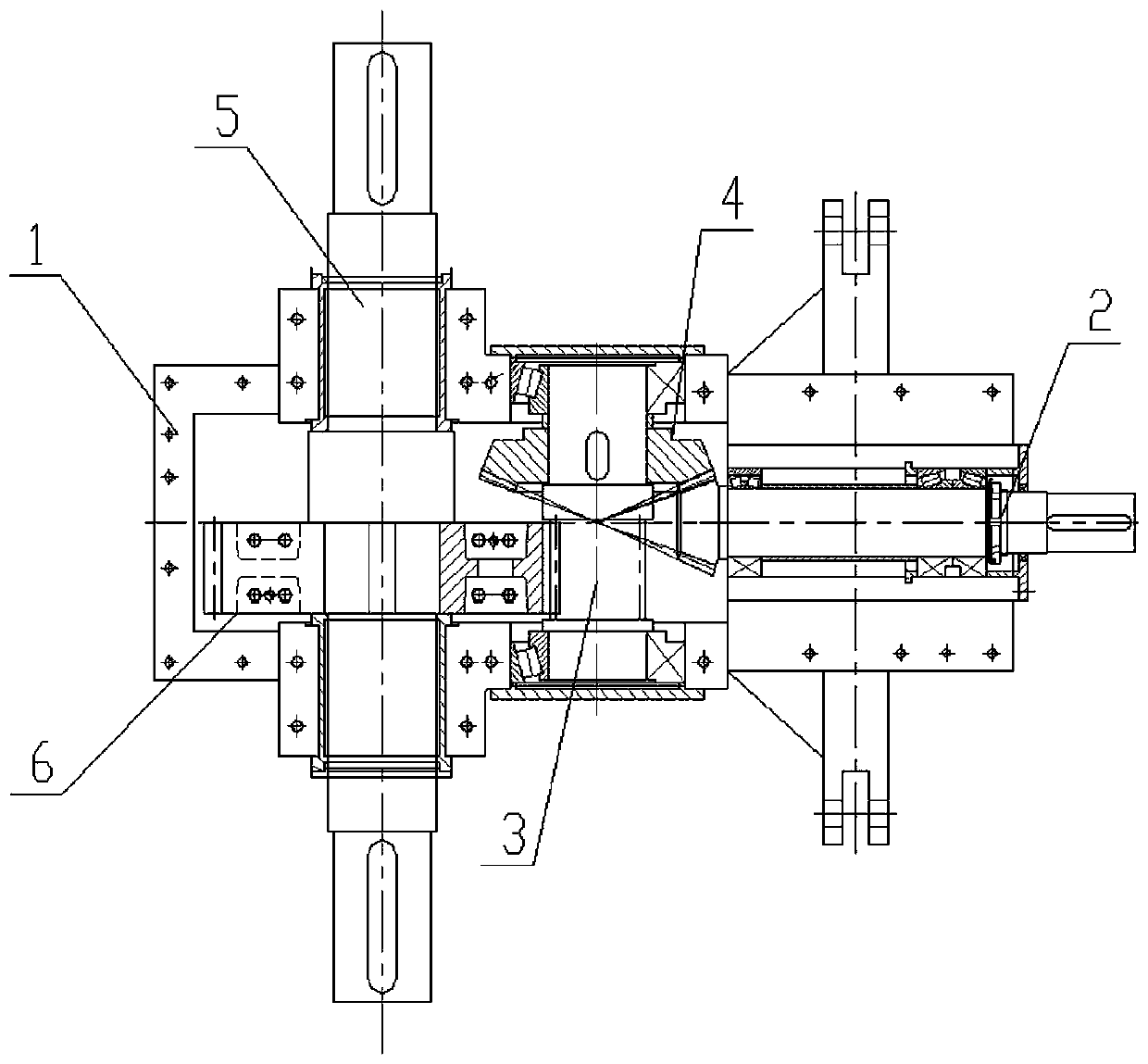

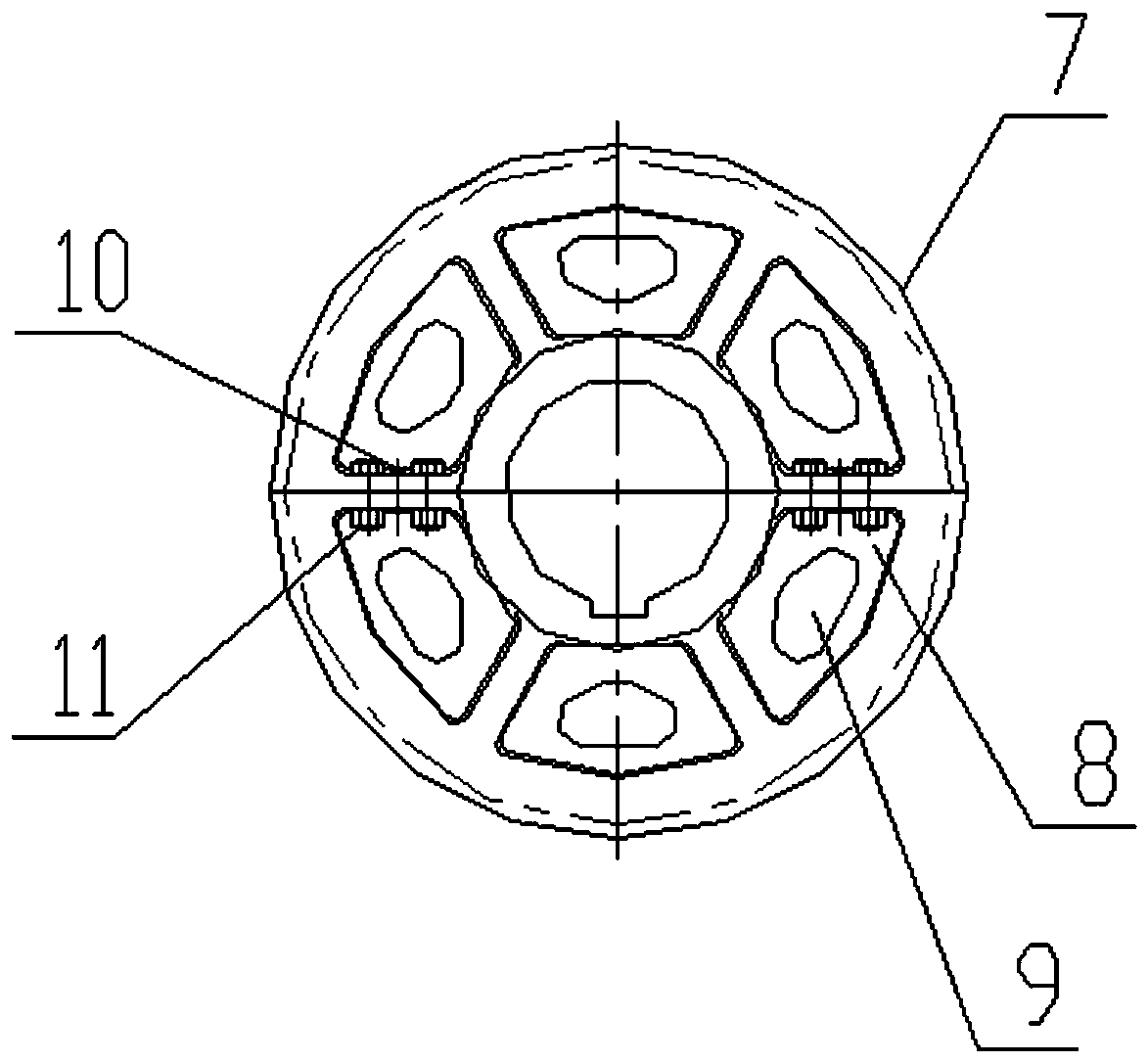

[0011] figure 1 , 2 Shown: a long shaft cutaway gear reducer includes a box body 1, a bevel gear input shaft 2, an intermediate shaft 3, a bevel gear 4, an output long shaft 5, and an output gear 6. The bevel gear input shaft 2 is formed by the box body 1 One side of the input meshes with the bevel gear 4 on the intermediate shaft 3 in the box, the intermediate shaft 3 and the output long shaft 5 are arranged in parallel in the box 1, the two ends of the output long shaft 5 protrude out of the box, and the output long shaft is connected by a key There is an output gear 6 meshing with the upper teeth of the intermediate shaft. The output gear includes two semicircular gears 7. A plurality of reinforced sinking grooves 8 with through holes 9 are evenly distributed on the front and back surfaces of the semicircular gears 7. The two semicircular gears Assembled into a complete circular ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap