Perforated strainer type heat transfer element for air pre-heater

A technology of air preheater and heat transfer element, which is applied in the field of boiler air preheater and flue gas heater. The effect of increasing the life, increasing the heat exchange area, and improving the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure and operating principle of a grate type air preheater heat transfer element provided by the present invention will be further described in detail below in conjunction with the accompanying drawings:

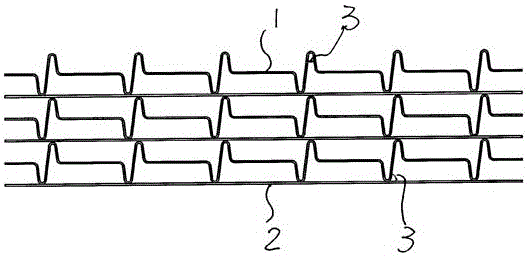

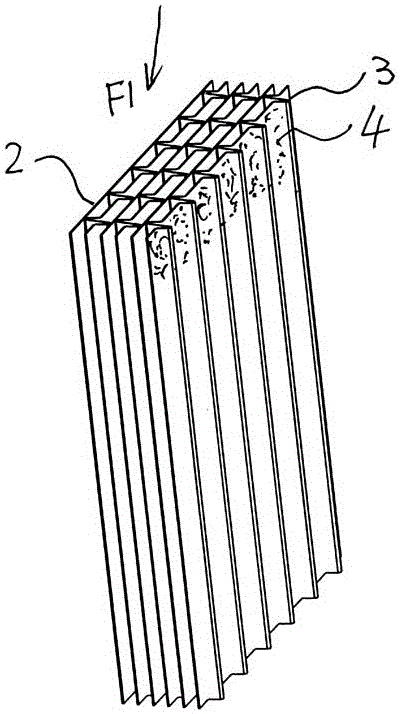

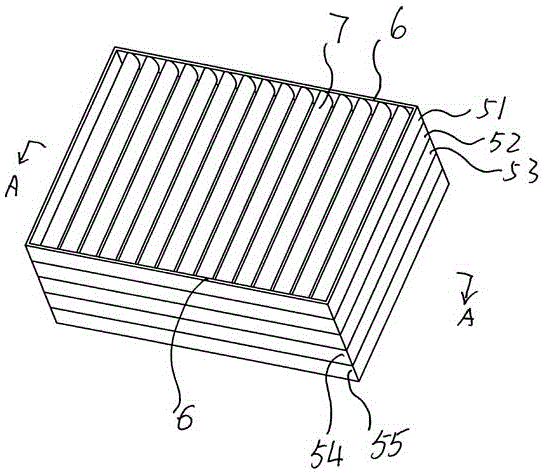

[0022] Such as image 3 , 4 As shown in and 5, the structure of a grate-type air preheater heat transfer element provided by the present invention is formed. According to the specifications of the air preheater compartment, several superimposed heat exchange units 51, 52, 53, 54 and 55, etc., the heat exchange unit is a grate-shaped structure composed of a number of bar-shaped metal heat exchange elements 7 fixed in parallel between two frames 6, and the heat exchange units 51, 52 stacked up and down , 53, 54 and 55 of the heat exchange units 71, 72 and 73 are arranged in a staggered arrangement (the sections of the heat exchange units 54 and 55 are omitted). With the heat transfer element of this structure, the high-temperature flue gas sent from the flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com